Introduction:

Tank and hull inspections are critical for ensuring the safe and efficient operation of oil and gas floating production and storage facilities and tanker ships. The challenges of maintaining hull integrity are numerous, including corrosion, fatigue, and structural damage.

In this article, we will explore the challenges of hull integrity management, as well as emerging technologies and approaches that may help address the challenges faced by this industry.

Challenges of Hull Integrity Management

Managing hull integrity presents a multitude of challenges, particularly when dealing with offshore and remote locations. External and internal care of hulls necessitates unique inspection methodologies. External inspections, conducted by specialized IRATA inspectors, are costlier. These inspections, involving operators suspended over the sea, focus on identifying issues such as corrosion, discontinuities, and welding problems.

Internal inspections, on the other hand, involve structural data diffused on multiple reports, obstacles in viewing, locating, mapping, and quantifying anomalies, and having data management, inspections, and repairs carried out in non-intuitive generalist systems. Besides, the delicate balance between inspection schedules and operational demands complicates the identification and resolution of potential issues before they become critical.

Inefficiencies in the inspection process can lead to HSE (Health, Safety, and Environment) risks as a consequence of structural problems, such as oil spills, while the time-consuming and labor-intensive nature of hull inspections, often requiring dry-docking, results in significant downtime.

The Naval Digital Tracking approach

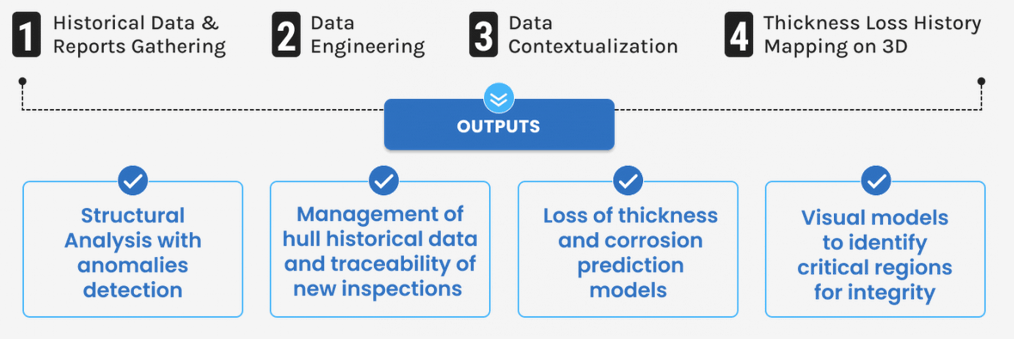

To address these challenges, leveraging enhanced asset management practices becomes imperative. Vidya’s Naval Digital Tracking application provides precise activity planning to ensure the structural integrity of the internal hull. By incorporating data analytics, predictive maintenance, and a 3D visualization environment supported by Artificial Intelligence, this innovative approach provides a comprehensive hull solution. Therefore, supporting inspection plans, maintenance actions, engineering analysis by the structural integrity team, and evaluation by the class society.

Vidya’s Naval Digital Tracking application involves contextualizing the historical integrity data (such as thickness measurements, temporary repair history, and measurements in critical areas, among others) in a 3D environment with thickness loss history mapped directly on it. In that way, the application enables:

- 3D representation maps thickness loss history, enabling

- structural analysis with anomaly detection,

- effective management of historical data,

- inspection traceability,

- prediction models for thickness loss and corrosion,

- visual models to identify critical regions for ensuring integrity.

Conclusion

In conclusion, the significance of tank and hull inspections cannot be overstated in maintaining the safety and efficiency of oil and gas storage facilities and maritime vessels. The integration of innovative technologies and best practices, exemplified by the Naval Digital Tracking approach, offers a path forward. Investing in digital solutions are crucial for enhancing safety, minimizing downtime, and achieving cost-effectiveness in the management of hull integrity within the oil and gas industry.

Fill the forms below to a deeper understanding of Vidya’s Naval Digital Tracking application