Intro

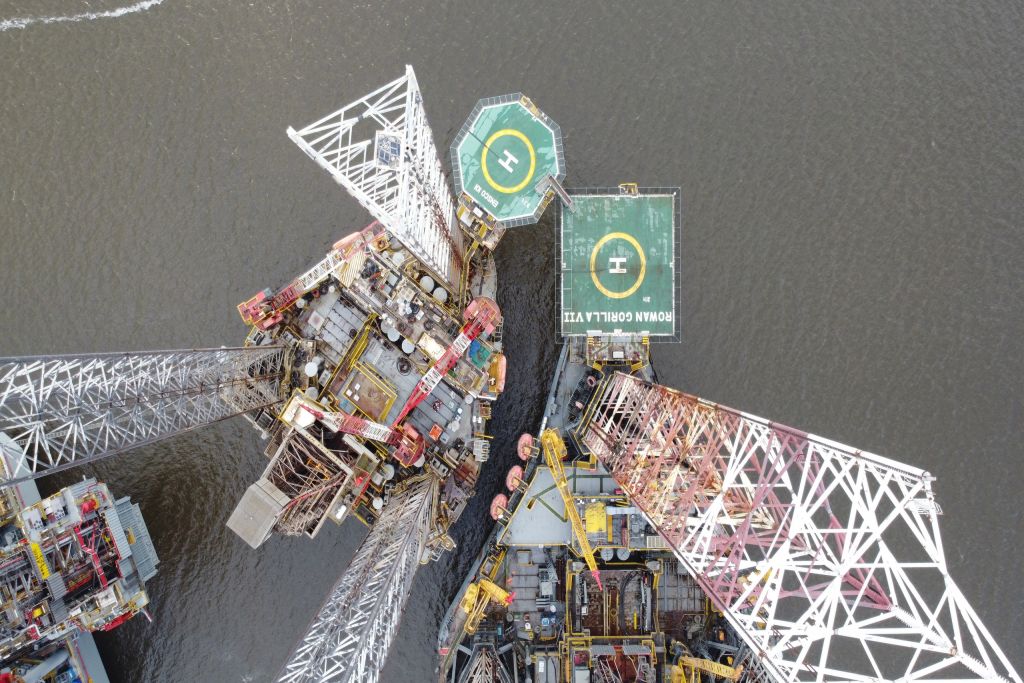

The oil and gas industry plays a critical role in powering our modern world. However, ensuring the integrity and safety of assets in this industry can be a very complex and dangerous task. Traditional inspection methods often involve significant manpower and time, along with potential safety risks due to the nature of offshore production processes. In recent years, remote inspection techniques have emerged as a game-changer, revolutionizing the way inspections are conducted in these kind of facilities.

In this blogpost, we will delve into the possibilities offered by remote oil and gas inspection, such as drones and 360 cameras.

Can Oil and Gas adapt to remote?

In a world where technology continues to transform industries at an unprecedented pace, the oil and gas sector is no exception. The implementation of remote inspection techniques represents a significant shift in how the industry approaches asset monitoring and integrity. However, as with any transformative change, there are challenges to be addressed and questions to be answered.

Reasons to adapt to remote inspections?

Technological Advancements:

Advancements in remote inspection technologies have paved the way for their integration into the oil and gas industry. With the introduction of drones, 360 cameras, companies now have access to a range of tools that can remotely assess asset conditions. These technologies enable inspections in areas that were once difficult or dangerous to access, allowing for a more comprehensive and accurate evaluation of assets.

Embracing Efficiency and Cost Reduction:

Remote inspection techniques offer the industry an opportunity to optimize efficiency and reduce costs. By eliminating the need for manual inspections, which often involve time-consuming processes and extensive manpower, remote inspections can be carried out more swiftly and with fewer resources. This allows companies to allocate their workforce more effectively and redirect resources to other critical operations. Additionally, the reduction in travel expenses associated with remote inspections can lead to substantial cost savings.

Enhancing Safety and Mitigating Risks:

The safety of personnel is of paramount importance in the oil and gas industry. Remote inspection techniques provide an opportunity to minimize human exposure to hazardous environments and mitigate risks associated with physical inspections. Drones, for example, can survey offshore platforms or pipelines without putting human inspectors in harm’s way. These tools can access confined spaces or areas with toxic gases, reducing the potential for accidents or injuries. By utilizing these remote technologies, companies can prioritize safety while maintaining the necessary level of inspection rigor.

Addressing Challenges

While the potential benefits of remote inspection techniques are evident, challenges must be acknowledged and addressed to ensure successful implementation. Adapting to remote inspection methods requires companies to invest in appropriate technology, train personnel in their use, and establish robust data management systems. Regulatory considerations, such as airspace restrictions for drones, need to be navigated. Moreover, ensuring reliable connectivity and data security is crucial to maintaining the integrity of remote inspections.

Finding the Right Balance

It is important to strike a balance between remote inspections and traditional methods, recognizing that certain inspections may still require hands-on evaluation. While remote techniques can provide valuable insights, they may not fully replace the need for on-site inspections in all circumstances. A hybrid approach that combines remote and physical inspections can offer the best of both worlds, maximizing efficiency and accuracy while still addressing specific challenges that may arise.

Remote Inspection Techniques

In the ever-evolving oil and gas industry, the need for efficient and reliable inspection techniques is of major importance to the production environment. Through an effective Integrity assessment industries are able to maintain a safe and continuous operation without unplanned downtime and safety to their workforce. In this scenario, remote inspection techniques have emerged as a powerful way of inspecting harsh environments, offering the potential to streamline reduced costs and enhanced safety.

When it comes to remote inspect an Oil plant, there are numerous technologies that have been employed in the task, such as:

Drones:

Drones have rapidly gained popularity in the industry for inspection purposes. Equipped with high-resolution cameras, thermal imaging, and other advanced sensors, drones can efficiently survey vast areas and inaccessible locations. They provide real-time video feeds, high-quality imagery, and detailed data, allowing inspectors to assess the condition of assets remotely. Drones are particularly suitable for upstream inspections, including pipelines, offshore platforms, and refineries, where they enable visual inspections, leak detection, and monitoring of structural integrity.

Cameras:

360 cameras offer a comprehensive view of the inspection site, capturing images and videos in all directions. These devices are portable and easy to use, enabling field technicians to conduct inspections without physically being present at the site. They are well-suited for midstream inspections, such as tank farms and storage facilities. 360 cameras provide a virtual walkthrough experience, allowing inspectors to identify anomalies, measure dimensions, and document conditions effectively.

Next Steps for the Oil and Gas Industry in Adapting to Remote Inspection

As the oil and gas industry embraces the benefits of remote inspection techniques, there are several key steps that companies can take to effectively adapt and optimize their operations.

These steps include:

Invest in Technology:

Companies should invest in the right remote inspection technologies that align with their specific needs and requirements.

Train Personnel:

To ensure the successful implementation of remote inspection techniques, companies need to provide comprehensive training to their personnel. Operators, inspectors, and technicians should be trained on how to operate the remote inspection equipment, interpret data, and make informed decisions based on the findings. Training programs should also cover safety protocols and best practices for remote inspections.

Establish Robust Data Management Systems

Remote inspection generates large amounts of data, including images, videos, and sensor readings. It is crucial to establish effective data management systems that can handle and store this data securely. Implementing data analytics tools can also help extract valuable insights and trends from the collected data, enabling predictive maintenance and proactive decision-making.

Navigate Regulatory Considerations

The use of remote inspection technologies, such as drones, may be subject to regulatory restrictions and airspace regulations. Companies must navigate these considerations and ensure compliance with applicable laws and regulations. Engaging with regulatory authorities and staying up to date with evolving guidelines will be essential in leveraging remote inspection techniques effectively.

Conclusion

The oil and gas industry is entering a new era of inspection practices, leveraging cutting-edge technology to enhance efficiency, reduce costs, and improve safety. Remote inspection techniques, including drones and 360 cameras, have emerged as powerful tools that enable companies to monitor assets and assess integrity in a more comprehensive and accurate manner.

By embracing technological advancements, investing in appropriate equipment, and training personnel, companies can unlock the full potential of remote inspection techniques. Overcoming challenges related to regulation, data management, and connectivity is crucial for successful implementation. Striking the right balance between remote and physical inspections allows companies to maximize the benefits while addressing specific requirements of different inspection scenarios.

As the industry continues to evolve, remote inspection techniques will play an increasingly significant role in ensuring safe and efficient operations. By embracing these innovations, the oil and gas industry can lead the way in leveraging cutting-edge technology for asset monitoring and integrity assessment, setting new standards for safety, efficiency, and sustainability.

Access and understand Vidya’s approach to remote inspection in Oil and Gas