Vidya Technology: Our Solutions

At Vidya Technology, we offer a range of digital solutions focused on APM (Asset Performance Management) to help industries optimize their operation and maintenance to improve performance. Our applications are designed to meet the specific needs of our clients and provide tangible, scalable, and fast results.

Our company is trusted by:

Our company is trusted by:

How Vidya’s solution lead operations towards Asset Performance Management

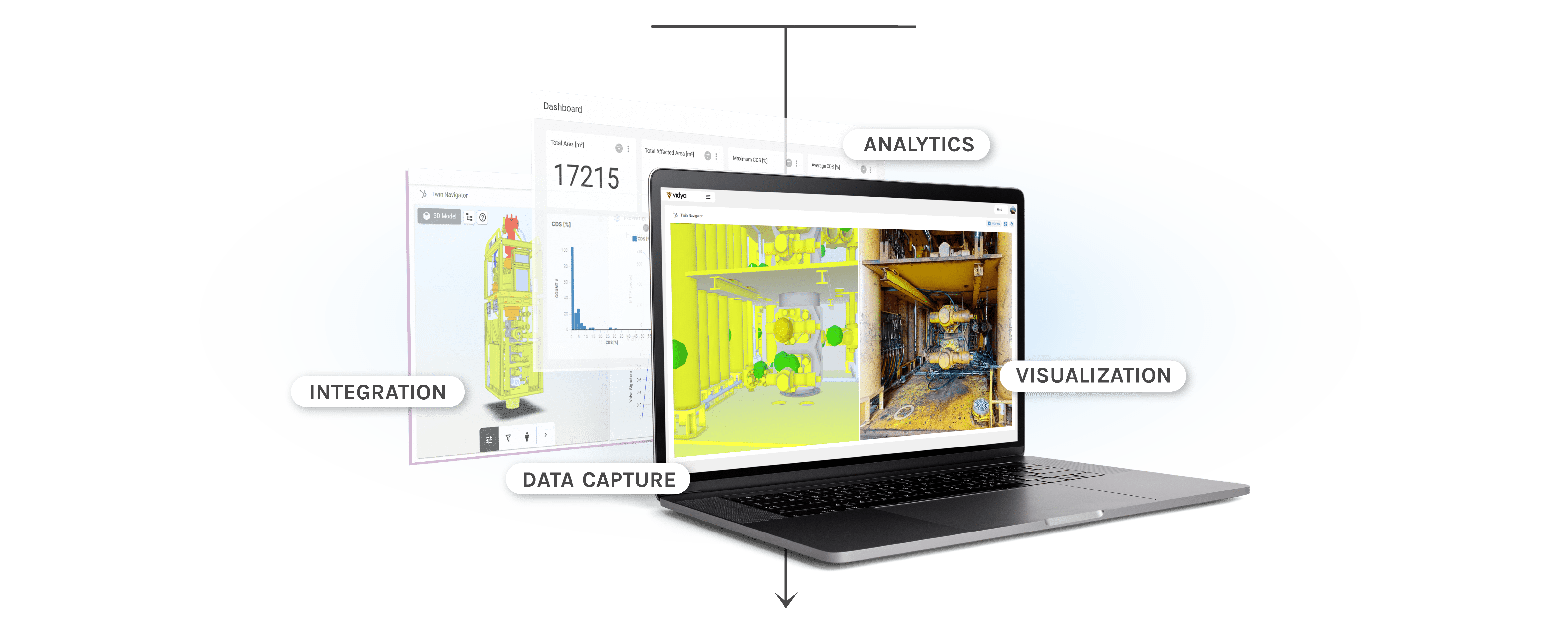

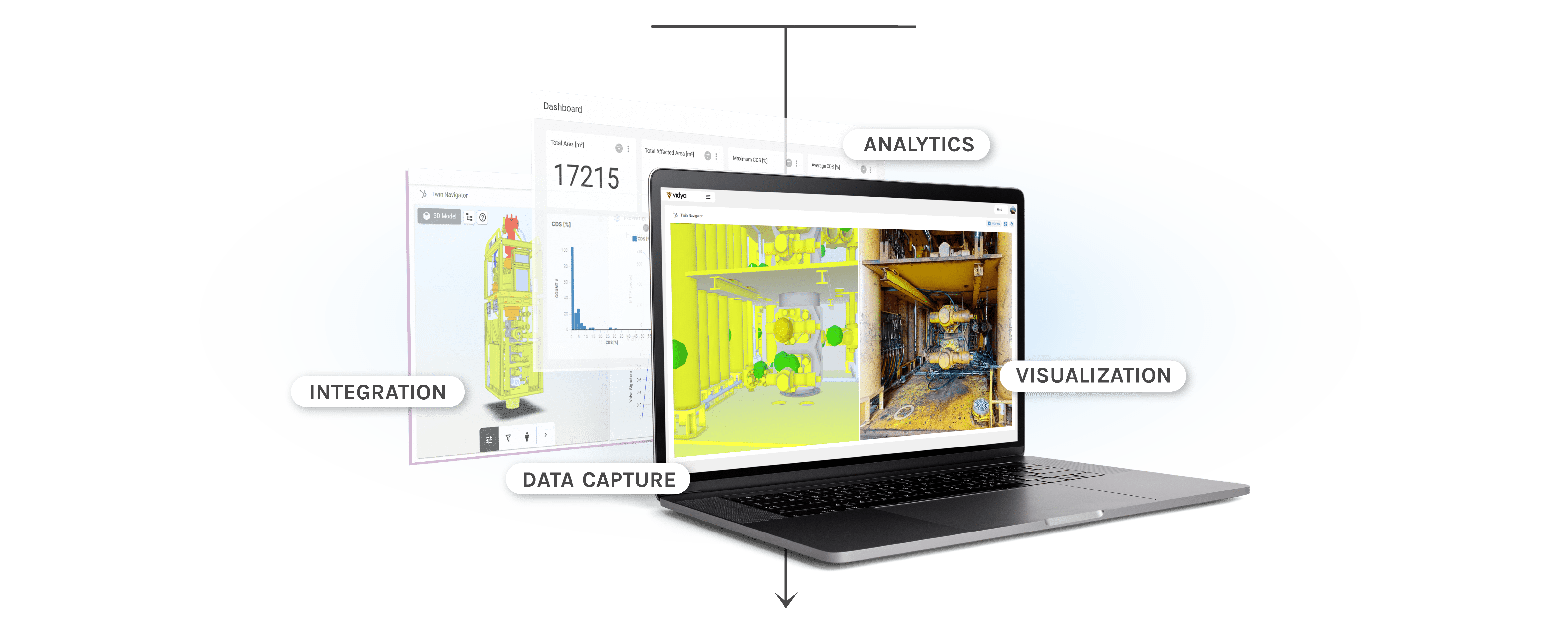

APM refers to an unified strategy that streamlines the process of maintaining assets through the capability of capturing accurate data, integrating it with aided visualization, and analytics to generate forecast regarding the availability, performance and reliability of assets – Gartner. Here’s how vidya’s applications interact with APM:

Integrity Management

Reliability

Asset Health Monitoring

Availability

Maintenance of Physical Assets

Vidya System Platform

How Vidya’s solution lead operations towards Asset Performance Management

APM refers to an unified strategy that streamlines the process of maintaining assets through the capability of capturing accurate data, integrating it with aided visualization, and analytics to generate forecast regarding the availability, performance and reliability of assets – Gartner. Here’s how vidya’s applications interact with APM:

Integrity Management

Reliability

Asset Health Monitoring

Availability

Maintenance of Physical Assets

Vidya System Platform

Digital Fabric Maintenance

Because your corrosion treatment can’t end in a report

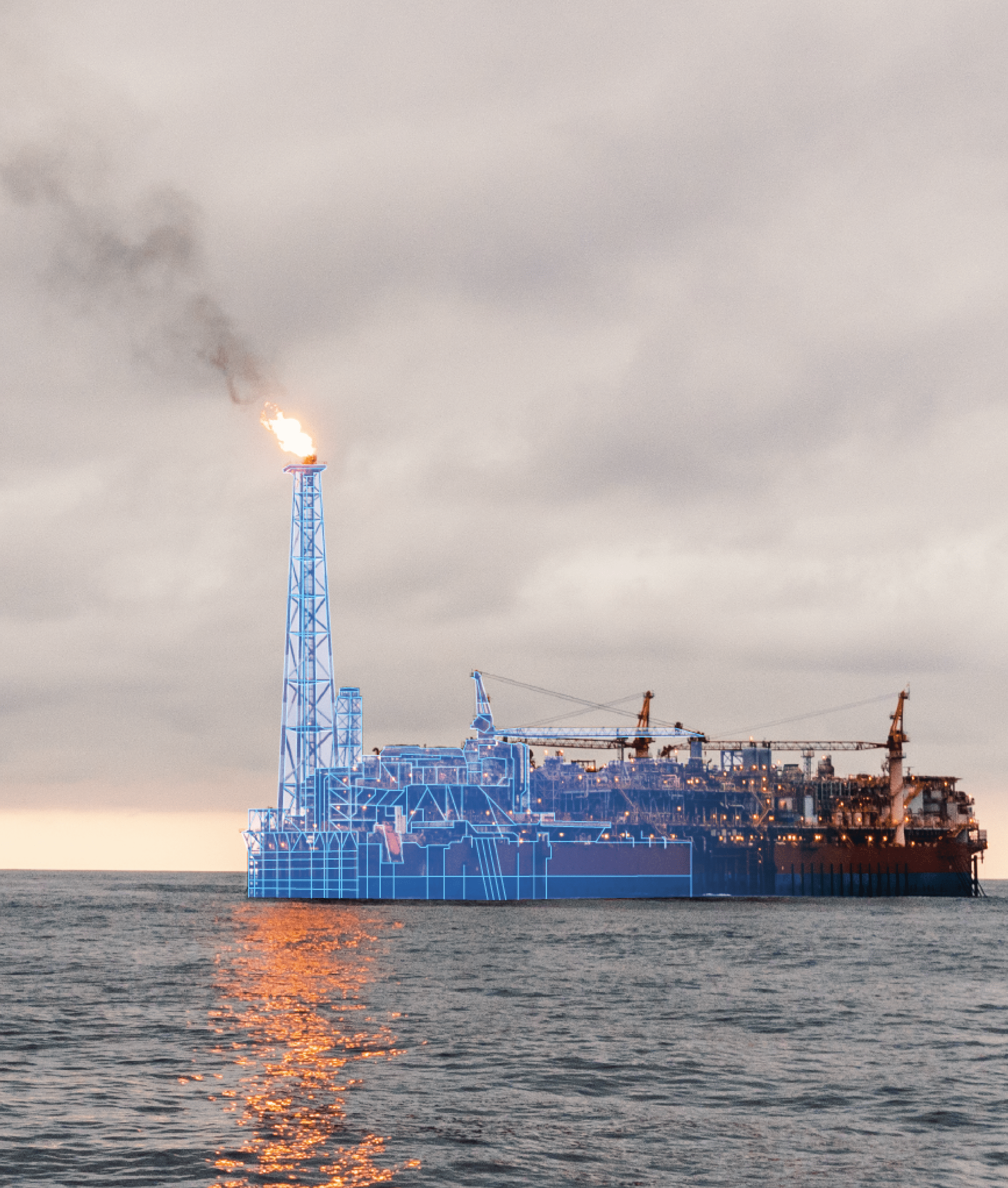

Corrosion is a widespread problem to Oil and Gas facilities. According to AMPP, the cost associated with corrosion management globally is estimated to be around US$ 2.5 trillion.

The Digital Fabric Maintenance application comes as a solution to this major problem and is the ideal application for streamlining your corrosion assessment with reduced PoB in highly corrosive environments.

From inspection to maintenance – DFM is enabling automated corrosion monitoring with the support of Artificial Intelligence autonomous corrosion identification and classification.

Digital Fabric Maintenance offers industries the possibility of identifying the real condition of their assets while enabling managers to accurately better use their resources.

Digital Hull Tracking

Transforming Drone Images into Hull Integrity outputs

Hulls are constantly exposed to harsh impacts, mechanical stress and high corrosion rates during operation. Precise Integrity is a central aspect of operational reliability. If not properly managed, problems can lead to leaks, significant maintenance costs and downtime.

Digital Hull Tracking is the ideal application for enhancing the process of managing Hull Integrity in marine vessels.

By identifying corrosion, cracks, discontinuities and welding problems through a 90% accurate Artificial Intelligence, the digital hull tracking enables proactive mapping, classification, and monitoring, providing accurate information for optimal engineering analysis.

Naval Digital Tracking

Transforming Hull Historical Data into Engineering outputs

Manually inspecting internal areas of Hulls can be a risky, challenging and often inaccurate practice that could lead to unplanned vessel repairs, oil leaks, penalties, and unnecessary dry-docking.

By placing historical contextualized integrity data on measurement points into a 3D model, we provide engineers with essential outcomes for their analytical work, inspection blueprints, and assistance for extended lifespan analyses.

Have access to precise data-driven support for engineering analysis, enabling accurate evaluation by regulatory compliance.

Digital Equipment Performance

Delivering AI-driven outputs for critical equipment performance

Predictive maintenance is key to operational efficiency, however having accurate data regarding the optimal time for intervention is equally fundamental.

Vidya’s Digital Equipment Performance is the ideal application for monitoring critical equipment performance and integrating large volumes of data.

By a meticulous data engineering process supported by artificial intelligence, this application enables faster mapping, analyzing, treating and correlating of available data.

Resulting in precise predictive analysis, reduced time between failures, and maintenance planning connected to ERPs and CMMSs.

Digital Structural Integrity

Improving Health, Safety, and Sustainability, while reducing downtime and maintenance costs

Just in Canada mining, corrosion wear is estimated to cost over C$15 billion for maintenance, repair and operations (MRO) in 2013.

The Digital Structural Integrity has been leveraging automated structural anomaly identification for this broad challenge.

Through the combination of deep expertise of miners’ and structural integrity engineers needs and high-level artificial Intelligence, Vidya has been able to leverage accurate use of available data and processing with Machine Vision, trained to the specifics challenges of mining operational environments.

By leveraging risk assessment, prioritization, and degradation acceptance, the solution had generated more than $1,000,000 savings by preventing unnecessary downtime.

Why choose Vidya?

Vidya is a company with extensive experience in the Oil and Gas and Mining industry. Our journey is characterized by the ability to deeply understand the context and challenges inherent in these industries. This expertise empowers us to develop AI-driven technology specifically tailored to effectively and accurately address the daily problems of operating in these sectors.

The opportunities and potential offered by the Management System from Vidya stand out for presenting a market differential where management gains significant added value through the provided tools, which are seamlessly integrated with the planning process.