Our company is trusted by:

Our company is trusted by:

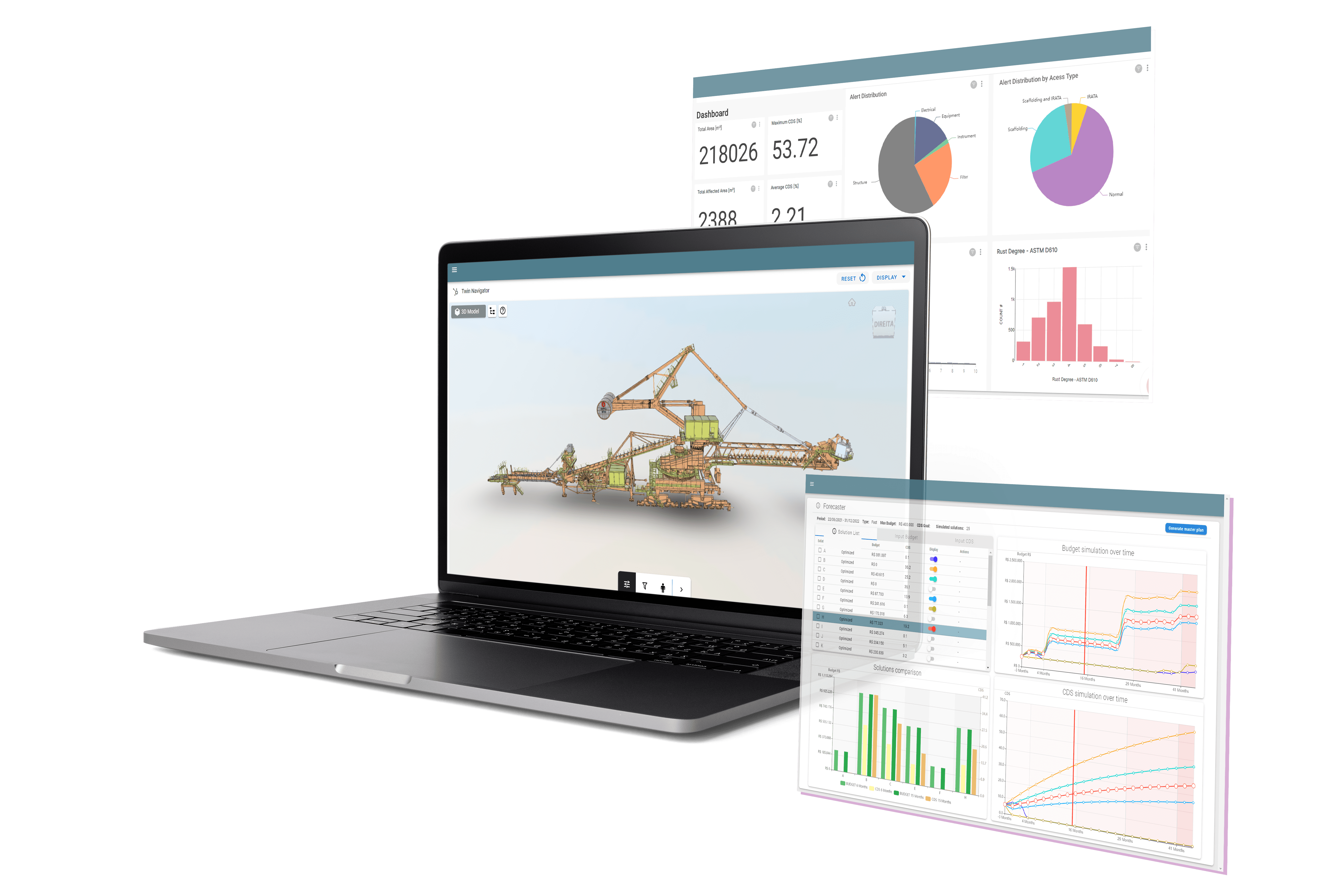

Using risk evaluation and degradation level of acceptance, the Digital Structural Integrity application prioritizes components and reduces in up to 42% the time and resources to plan maintenance actions.

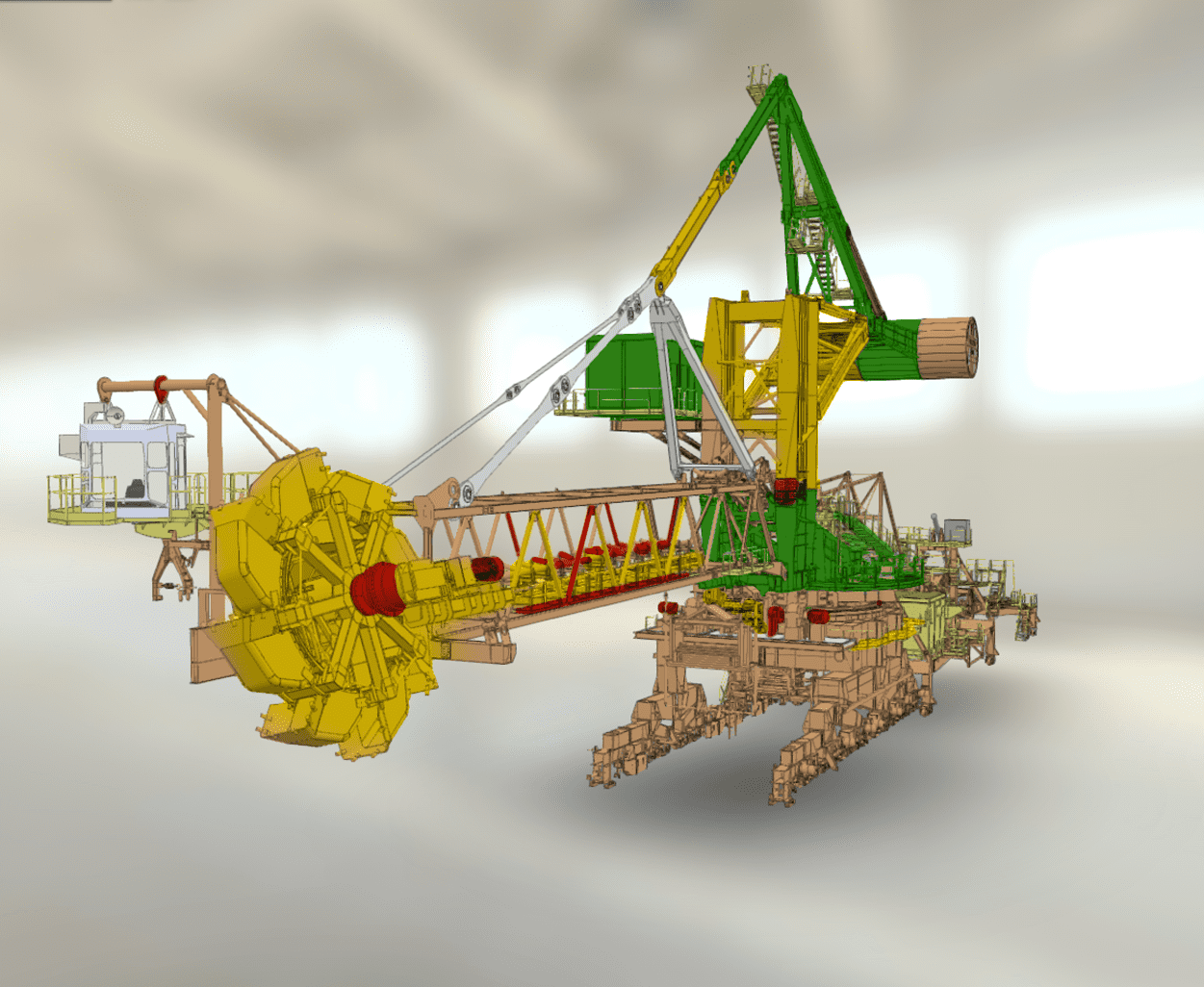

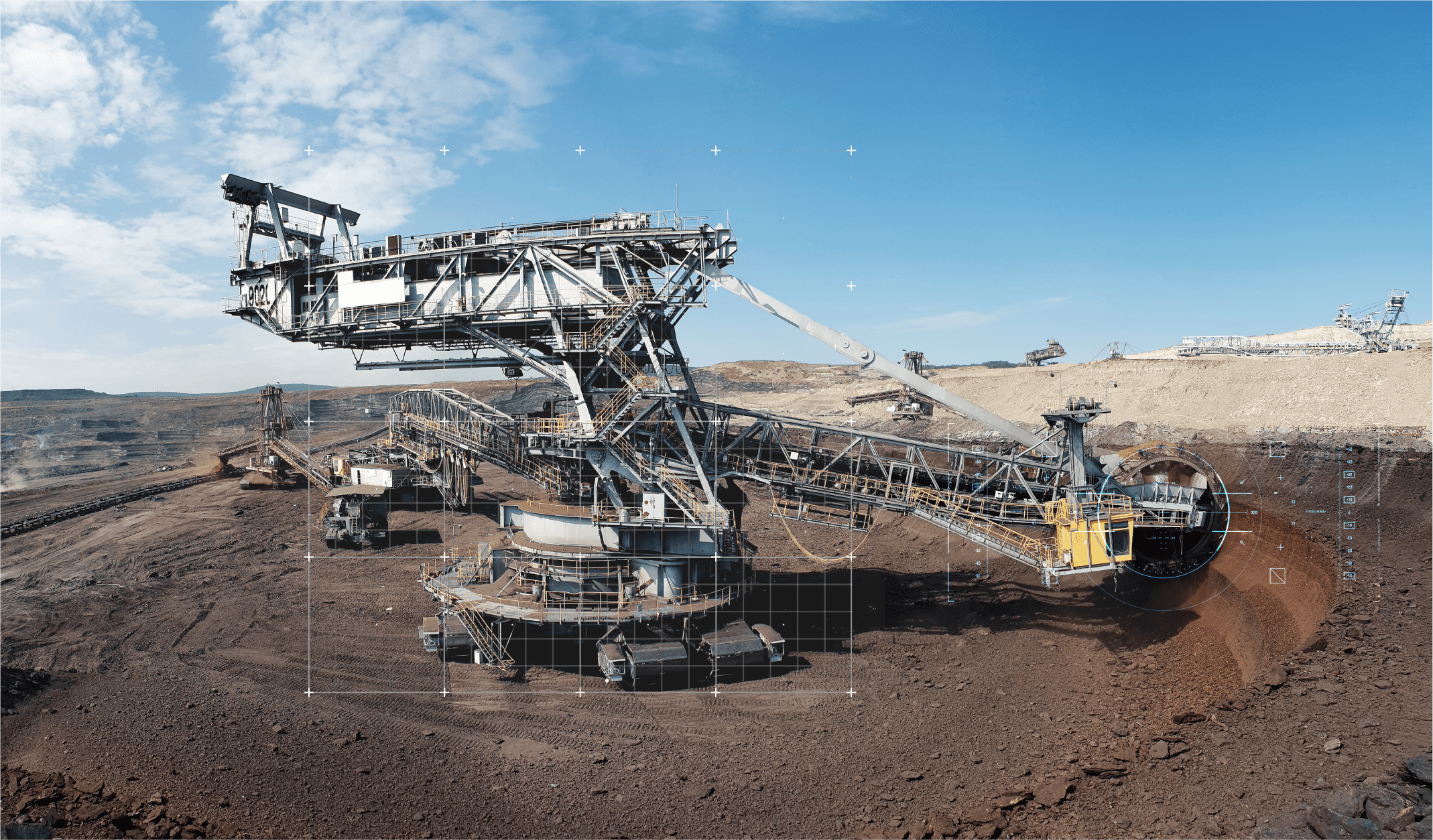

Vidya’s Machine Vision performs effectively even in environments characterized by substantial dirtiness. It analyzes, marks, and identifies structural anomalies and corrosion while strictly adhering to the company’s visual inspection standards, such as ISO 4628-3.

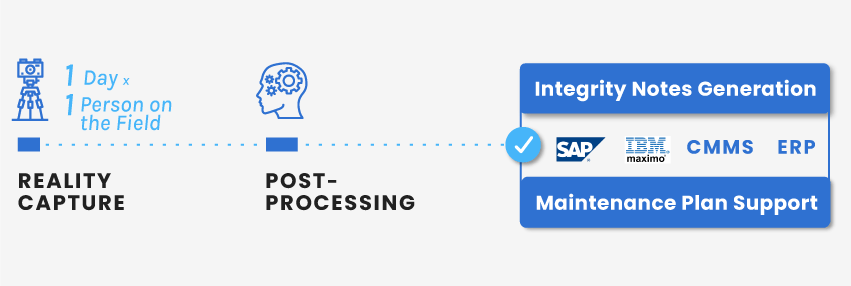

How we fulfill the integrity assessment

Combining reality capture and machine vision, the application reduces the number of people on field in up to 86% and provide more control over the structural integrity management, reducing unplanned downtime and improving the Health, Safety and Environment of the company and completed in just 30 days.

Assertive results for maintenance plans in 30 days:

Contact us to learn how this solution fits your operation

Beyond a digital solution, we deliver structural integrity outputs for you. By scheduling a meeting, we will:

- Acknowledge your prime concerns and the initiatives you are doing to trying to solve them.

- Present our Digital Structural Integrity solution and the results we’ve achieved in the structural management.

- Identify how we can help you improve your structural integrity management and monitoring.