What if the smallest corrosion sign on a pipeline went unnoticed during inspections? And what if that small signal triggered a multimillion-dollar shutdown or, worse, a catastrophic accident? For decades, corrosion treatment has relied on slow, manual inspections that stretch across massive assets, often missing the anomalies that matter most. The stakes are brutal: safety risks, unplanned downtime, and escalating maintenance costs.

Now, AI is rewriting this story. By combining computer vision, machine learning, and connected data ecosystems, industries are turning corrosion treatment from a reactive task into a predictive process. But how exactly does AI achieve what traditional methods couldn’t? And why is it becoming indispensable for the energy sector?

How the Industry Traditionally Handles Corrosion Assessments

To understand how AI is applied to corrosion treatment, it’s important to first examine why the demand for it emerged. Before AI, corrosion detection alone could take months, requiring dozens of professionals to inspect facilities spanning over 200,000 m². And while inspections are a fundamental step in addressing corrosion, they represent only a fraction of the full workflow: maintenance planning, coating, and decision-making would still add several more months to the process.

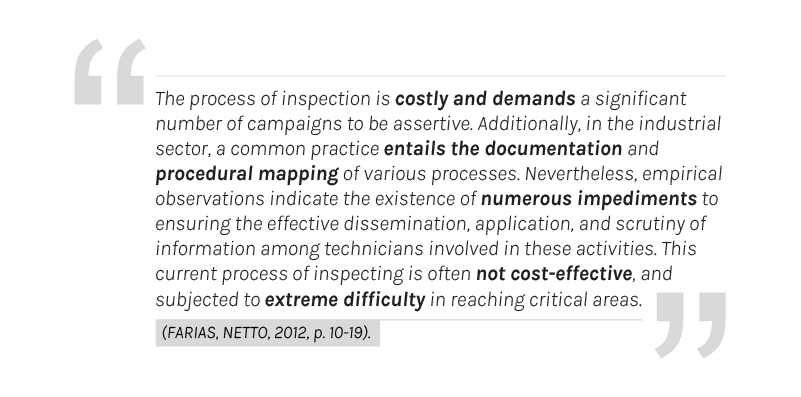

In this manner, treating corrosion involves balancing an inherently time-consuming process, budget constraints, and risk exposure for the people in the field. According to B.V. Farias, in his article “FPSO hull structural integrity evaluation in Bayesian updating of inspection data”:

Aside from generating a robust and fragmented workflow, traditional corrosion treatment displays a low capability to visualize the problem, its ramifications, and possible root causes. This challenge becomes even greater in difficult-to-reach areas, such as subsea structures, high-elevation piping, or confined spaces within processing units. In such environments, inspections demand specialized equipment and increase the likelihood of missing subtle corrosion signals due to limited visibility and access restrictions. The result is a reactive cycle where issues are only addressed once they have already escalated into visible damage, forcing industries to deal with higher costs, greater risks, and prolonged downtime. Under such conditions, companies must deal with specific obstacles, such as:

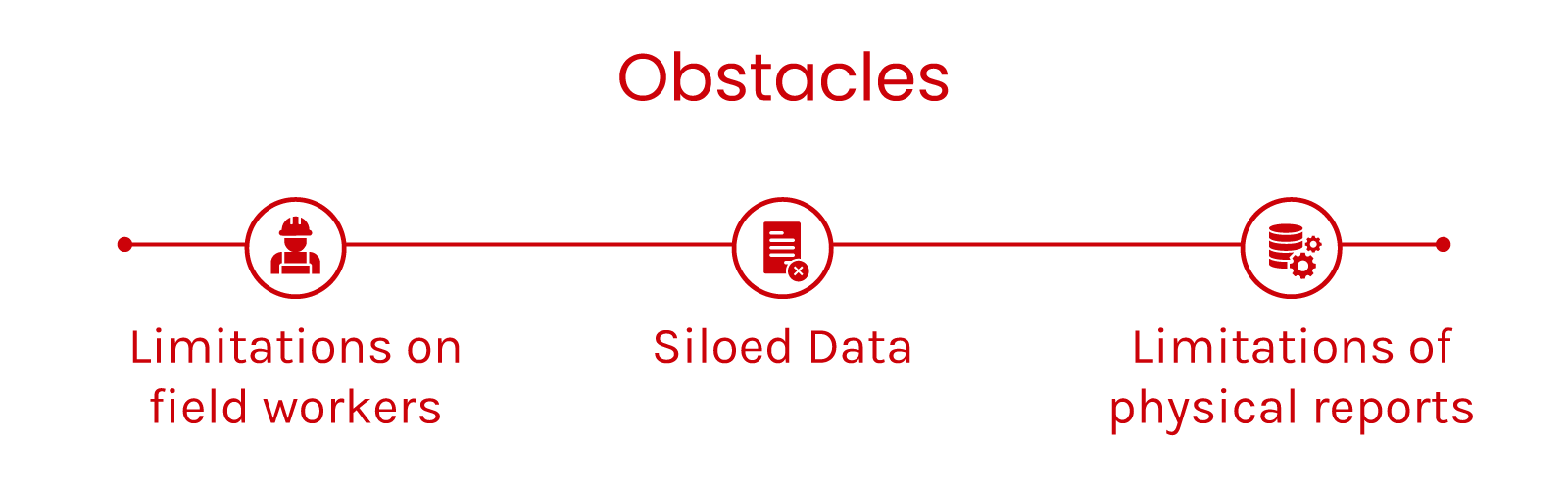

1. Limitations on field workers

Addressing corrosion involves allocating professionals to inspect an inherently hazardous environment. Thus, companies have to simultaneously deal with limitations on the number of people allowed in the field and the necessity of a specialized workforce to solve occurrences. And, while corrosion progression doesn’t stop, asset activities must be paused to perform mitigation actions.

In this scenario, field professionals face multiple challenges related to safety, logistics, technology, and human factors when displaced to industrial operations. It encompasses the remote location of the operation, difficult-to-access areas, dangerous activities that require rope access, unstable weather, and isolation from their families for extended periods. And, while reducing the fieldwork count may appear straightforward, professional intervention remains essential to monitor the asset’s health.

2. Siloed data

Another significant challenge is the integration of diverse data sources. Industrial facilities rely on various systems for data collection and thousands of documents for storage. This data is often unstructured, unprocessed, untreated, and presented in various forms as spreadsheets, reports, on-premises systems, or cloud systems. According to Forbes, despite industries collecting vast amounts of data, 60% to 73% of this data has yet to be successfully used for any strategic purpose.

Additionally, the Journal of Petroleum Technology reported that 80% of employee time in the offshore industry is spent looking through unstructured data to inform decisions. This means countless hours cross-referencing documents and systems just to interpret the scale and relevance of corrosion anomalies. Without contextualization, this data cannot provide a holistic view of corrosion anomalies or reveal patterns that support better decisions. To move forward, industries must adopt data strategies that preserve organizational memory and, more importantly, provide context to the information they collect.

3. Limitations of physical reports

While diffused data limits context, physical reports challenges arise from how information is organized and shared across disciplines. In most operations, corrosion is still treated through a fragmented and highly manual process. Inspection results are stored in static documents like spreadsheets, PDFs, or scanned reports, while maintenance records sit in separate databases or legacy systems. Engineering teams manage their own files, and risk assessments are updated manually and independently of operational data.

In offshore cases, corrosion inspections often result in reports exceeding a thousand pages, packed with images and detailed information. Engineers must interpret these documents to pinpoint the findings, which accumulate in the thousands of reports on an offshore platform. On top of that, inspectors are not fully integrated into the broader maintenance process, which creates gaps between data collection, effective decision-making, and maintenance execution.

This siloed management approach forces constant reconciliation between teams, consuming valuable time just to align existing knowledge. When inspection data isn’t directly tied to maintenance schedules or risk models, critical issues can remain buried in reports or lost during handovers. As a result, interventions become reactive rather than predictive, and planning cycles are built on assumptions instead of evidence.

The role of AI in corrosion detection

Given the complexity and scale of energy industry operations, traditional inspection methods are no longer sufficient to guarantee timely and reliable integrity decisions. AI addresses this gap by transforming corrosion assessment from a fragmented, reactive cycle into a connected, predictive process. Instead of relying solely on human interpretation, AI models are trained on hundreds of thousands of field images to automatically identify corrosion signals, even in their earliest stages. However, automatic corrosion detection has its limits, as the identified findings still need to be prioritized and integrated into the maintenance workflow.

After corrosion is detected, these algorithms can predict its growth, estimating its rate of progression, and providing a clearer understanding of how the anomaly might evolve. In this scenario, AI leverages the opportunity to connect different teams and systems and ensures they can communicate and share data seamlessly. The output is to have all the anomalies mapped, classified, and prioritized according to operational rules, supporting engineers in maintenance routines with data-driven insights.

AI-Based Corrosion Assessment

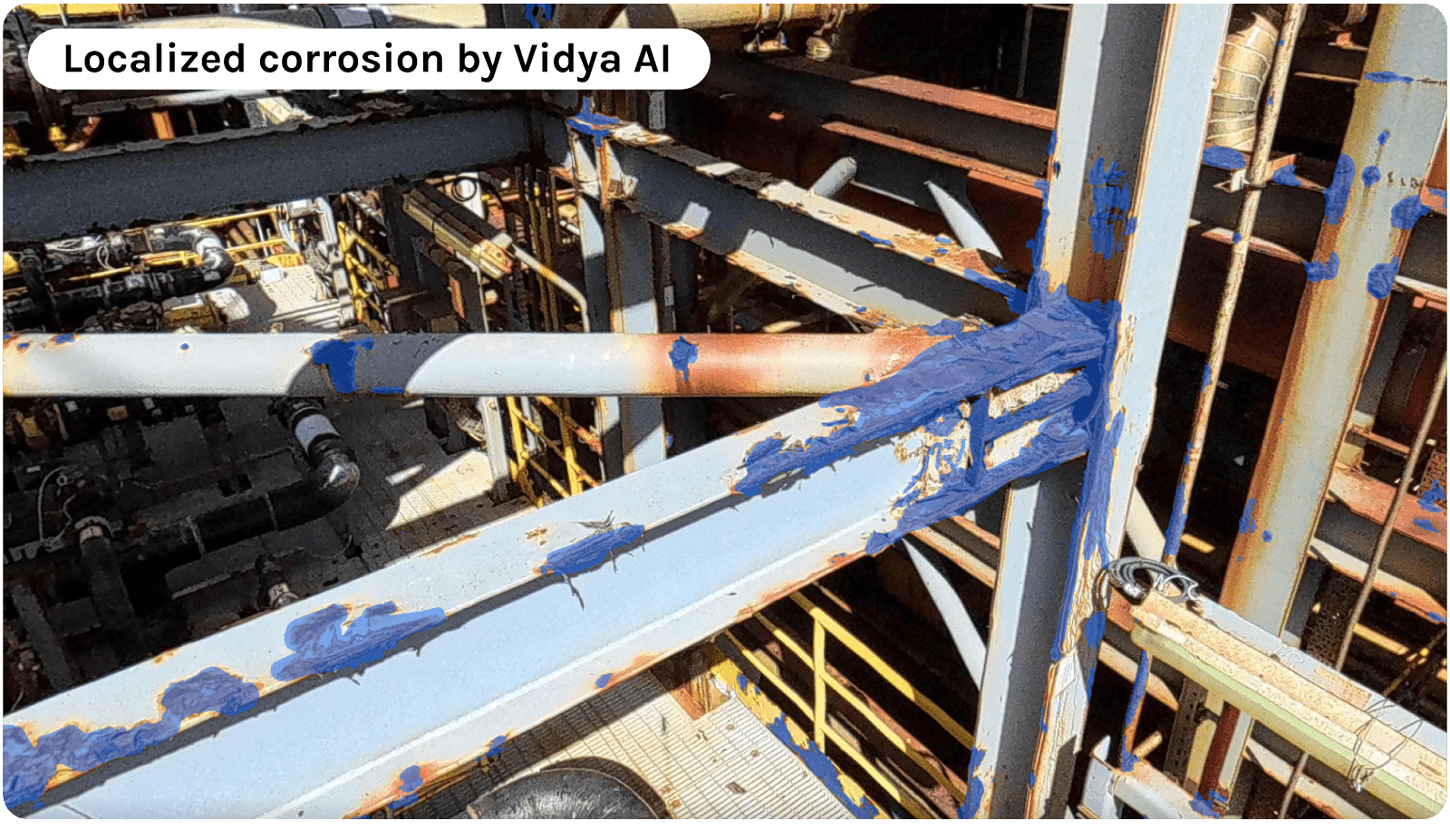

Unlike traditional inspections that rely on visual checks and manual reporting, Vidya Technology, a global company in AI-driven Asset Integrity Management for large-process industries, developed an AI-based corrosion assessment method that uses machine vision to process field images and automatically detect early signs of damage. Trained on large datasets of industrial images, deep learning models can recognize corrosion patterns with high precision, even under poor lighting or in complex environments where human visibility is limited, allowing the replacement of the General Visual Inspection (GVI) process.

Once corrosion is identified, the algorithms go further by classifying the type of anomaly according to the ‘’ASTM D610’’ and ‘’ISO 4628’’ standards, mapping its location, and predicting its progression over time. This predictive capability helps engineers anticipate risks, prioritize maintenance activities, and avoid unnecessary shutdowns. In practical terms, what once required months of manual inspections can now be achieved in days, with far fewer people exposed to hazardous fieldwork.

To enhance accuracy, transfer learning techniques are applied. By leveraging pre-trained models originally developed for large image datasets, AI can detect corrosion patterns more effectively, even when industrial datasets are relatively small or noisy. According to Kaizer (2021), the application of U-Net deep learning networks in corrosion detection showed that transfer learning significantly improves results, making it possible to achieve higher accuracy even with challenging image conditions.

This finding is particularly relevant for field environments where lighting and image quality are rarely ideal. Kaizer (2021) also highlights that, despite these constraints, deep learning models were still able to generate detailed segmentation masks, pinpointing corrosion areas with precision. Such results reinforce the value of applying advanced machine vision models to real-world industrial operations.

The approach also brings significant safety and cost benefits. By reducing the number of professionals needed for rope access, offshore deployment, or confined-space inspections, AI minimizes operational risks and cuts inspection-related expenses. Instead of overwhelming teams with fragmented reports, Vidya’s algorithm calculates the affected area by corrosion and supports mitigation actions by estimating the area to be painted.

As shown in the image above, AI models identify corrosion on asset images and map it onto the 3D model by linking the pixels showing corrosion to their corresponding locations. This flags a corrosion finding for the element and its TAG in the digital twin, making it easier to validate anomalies, prioritize high-risk areas, and accelerate decision-making. The result is a visual map of corrosion occurrences, enabling engineers to quickly confirm findings, focus resources where they’re most needed, and plan interventions before minor defects escalate into serious structural threats.

Connecting Corrosion Diagnostics to Integrity Cycles

The value of AI in corrosion management doesn’t end with detection. For asset-intensive industries, the real challenge is ensuring that corrosion findings are not just captured but also integrated into the integrity cycle from inspection through to mitigation and long-term planning.

AI enables this integration by automating General Visual Inspections (GVIs), generating a consistent stream of findings that feed directly into the integrity workflow. With anomalies automatically mapped and tagged in the digital twin, inspection data is no longer confined to static reports. Instead, each finding becomes a living element of the asset’s integrity cycle, ready to be tracked, prioritized, and acted upon. But how exactly can AI predict corrosion growth? And can it compare that prediction with resource allocation and business priorities?

Predict your Integrity with Vidya’s CDS and Forecaster

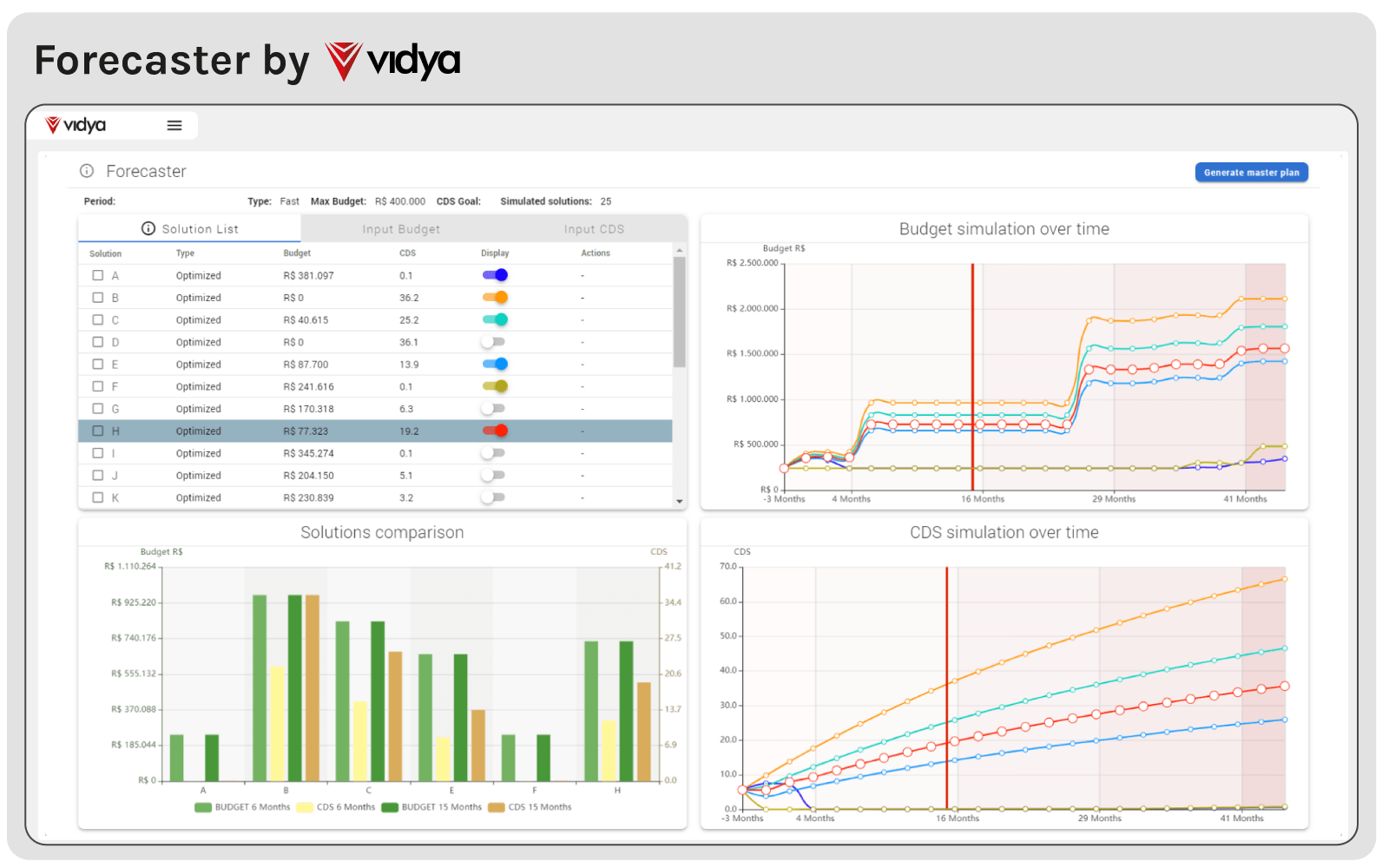

To evaluate the consequences of corrosion degradation to operational components, such as the status of protective coating and affected areas, Vidya developed a proprietary algorithmic model, the CDS (Corrosion Degradation State). As a long-term prediction model, it uses the lifecycle data of each asset to fine-tune its predictions, providing an estimate of the corrosion evolution over time.

Beyond that, Vidya also developed an AI capable of predicting budget allocation for maintenance planning: The Budget Forecaster. This algorithm is a multi-objective optimization model that simulates different budget scenarios by crossing conflicting objectives, such as budget, People on Board/Field, Risk Models, and even the evolution of corrosion, with comparisons with the CDS model. Thus, it offers different scenarios on how the level of integrity will perform at different resource applications based on trade-offs between the objectives.

This foundation allows Critical Visual Inspections (CVIs) and Non-Destructive Testing activities (NDT/NDE) to be executed more strategically. Rather than deploying teams reactively, engineers can focus on anomalies that matter most, supported by a continuously updated list of findings. Over time, these diagnostics create a closed loop: new corrosion detections feed into mitigation planning, results of interventions are logged back into the system, and predictive models like Vidya’s CDS (Corrosion Degradation State) refine their forecasts with Machine Learning capabilities in every cycle.

The connection also extends to resource allocation. By linking diagnostics with the Budget Forecaster, companies can simulate scenarios that weigh corrosion growth against available budgets, workforce constraints, and risk models. This transforms integrity management into a dynamic process where each inspection not only reveals the current state of the asset but also informs strategic trade-offs about how to preserve it in the future.

In practice, this means corrosion is no longer treated as a series of isolated anomalies but as part of a continuous integrity cycle. AI ensures that every detection, every inspection, and every intervention strengthens the overall lifecycle management of the asset from detection to resolution.

How is AI-based corrosion assessment applied to real-world scenarios?

Despite Vidya’s technology already being applied in over 27 assets, from entire FPSO fleets to mining structures such as conveyor belts, stack reclaimers, and ship loaders, one of the most representative applications took place on a U.S. offshore Floating Production System (FPS). In this case, the operator faced average cycle turnover exceeding 150 days from issue detection to resolution, inconsistent and fragmented field data, and difficulties in consolidating risk data holistically. By adopting Vidya’s Digital Fabric Integrity (DFI), the company transformed its corrosion management, achieving full asset integrity in just six days and drastically improving efficiency, safety, and cost control.

Conclusion

Corrosion has long been one of the most persistent threats to industrial assets, but its treatment no longer needs to be slow, reactive, and uncertain. By embedding AI capabilities into corrosion treatment, the energy sector is redefining how facilities are preserved: moving from damage control to foresight. Thus, the path ahead is clear: organizations that embrace AI-driven corrosion management will not only safeguard their operations but also secure a stronger, more resilient future.