Curitiba, June 13th, 2025

Vidya Technology announces the launch of its Digital Asset Integrity Management Suite, a set of integrated tools that enables full control over the integrity lifecycle from detection to resolution. Combining Artificial Intelligence, Digital Twins, and Spatial Computing, the new solution delivers a contextualized, end-to-end visualization of physical assets, allowing faster and better-informed decisions while enhancing safety, reducing downtime, and cutting operational costs.

Originally founded at COPPE/UFRJ, Vidya has become a recognized player in offshore software solutions. Its visual inspection automation technology, which uses computer vision to measure and classify surface corrosion, currently holds 57% of the private market share in Brazil for that segment.

While Vidya’s roots are in the oil and gas industry, its solutions are now being applied across sectors such as mining, maritime, petrochemicals, manufacturing, infrastructure, and renewable energy. “Every industrial plant, no matter the sector, faces the same fundamental question: how do you ensure asset integrity?” says CEO Otavio Correa.

According to Correa, the idea for the suite emerged from direct market feedback: “We saw that clients were looking for more than a corrosion solution; they recognized the potential of our digital twin to support a wide range of integrity processes.”

In response, Vidya mobilized its engineering team, brought in integrity specialists, and invested in new development to create a robust and modular platform. The goal: to centralize and optimize all asset integrity processes in a single, adaptable system.

“The suite’s robustness and depth ensure that most, if not all, integrity processes can be consolidated within the platform,” Correa explains. “But what makes it work is the ability of each module to adapt to the specific routines, rules, and challenges of each client.”

It was precisely this flexibility across different industry practices that drove the decision to develop a modular architecture: “No two companies have identical integrity processes. There are similarities, yes, but differences matter. The modular design lets us support both specific needs and full-scale integrity programs. Whatever the challenge, the suite can adapt.”

Structured around the Deming Cycle (Plan, Do, Check, Act), the suite includes eight independent modules, each supporting traceability, standardization, and continuous compliance:

- Digital Fabric Integrity

- Non-Destructive Testing (NDT)

- Static Equipment Integrity

- Digital Dropped Objects (DROPS)

- Risk-Based Inspection (RBI)

- Temporary Repairs

- EX Inspection

- Digital Structural Integrity

Together, they form an Asset Integrity Data Management System, focused on unifying all information and workflows related to asset integrity, from planning and standardization to execution and field traceability.

This approach doesn’t just replace traditional and fragmented systems; it consolidates everything in one digital environment, integrated with ERPs and corporate systems like SAP, IBM Maximo, Oracle, and TOTVS.

A Connected Workforce

One of the suite’s standout features is its mobile interface, nicknamed the “pocket twin.” It enables users to interact directly with a 3D model of the asset, providing practical access to data, work plans, and inspection records, even offline.

The tool also includes advanced computer vision and AI capabilities to automatically detect anomalies and populate the integrity backlog with real-time data from operational environments.

Fully compliant with leading technical and regulatory standards (ISO, ASTM, ABS, PPIM), the platform streamlines compliance without adding friction or bureaucracy. Every action, data point, and inspection is fully auditable.

Growing the Technology Portfolio

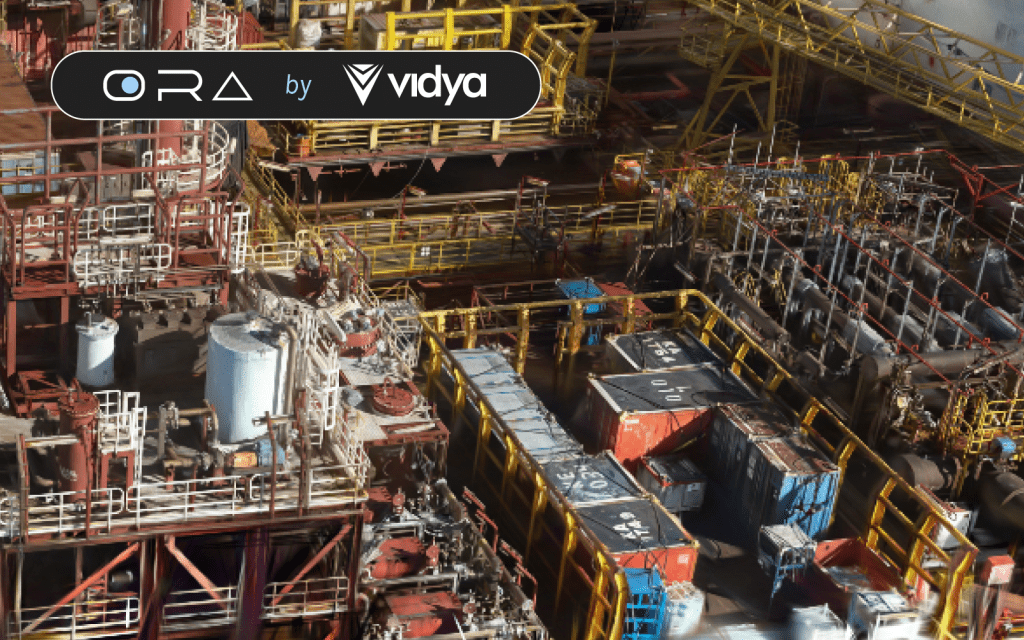

This marks Vidya’s second major launch in 2025. Back in March, the company introduced Ora Viewer, a browser-based tool that uses spatial computing and AI to deliver ultra-realistic 3D environments for immersive visualization of industrial assets.

By combining cutting-edge technology with the practical realities of industrial operations, Vidya reaffirms its commitment to industrial digital transformation, delivering flexible, field-ready solutions that meet the evolving needs of frontline operations.