In large-process industries, static equipment such as pressure vessels, piping, and storage tanks represents the majority of operational machinery. While these assets may not move or rotate like pumps or turbines, their failure can be equally catastrophic, leading to safety incidents, production losses, and regulatory penalties.

Understanding the nature and function of these assets is the first step toward building a robust and auditable integrity management framework. And, given the scale of risk involved, ensuring the integrity of static equipment is both a regulatory obligation and a strategic necessity. But what exactly qualifies as static equipment? And why does its compliance play such a critical role in industrial operations? This blog explores 5 Steps to Strengthen Your Static Equipment Compliance Strategy.

What is Static Equipment?

Static equipment refers to non-moving components in a plant or facility that perform vital containment, transfer, or storage functions. In the energy industry, this includes:

- Pressure vessels

- Storage tanks

- Heat exchangers

- Columns and reactors

- Separators

- Furnaces

- Boilers

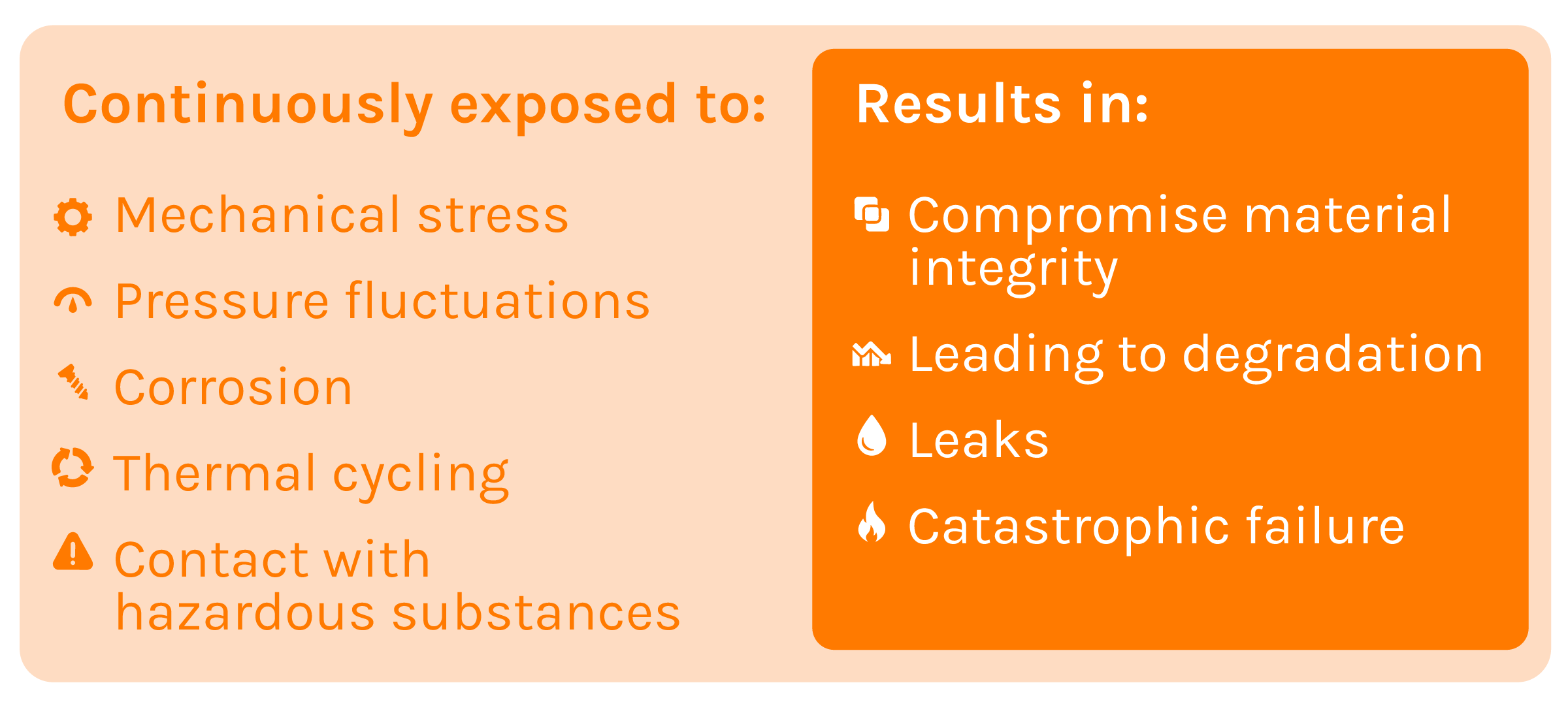

Although static equipment has no moving parts, it is continuously exposed to mechanical stress, pressure fluctuations, corrosion, thermal cycling, and contact with hazardous substances. Over time, these conditions can compromise material integrity, leading to degradation, leaks, or even catastrophic failure. Such events often result in serious consequences, including process shutdowns, environmental damage, safety incidents, and regulatory violations.

To prevent these risks, static equipment must remain fully compliant with regulatory standards that govern its design, fabrication, inspection frequency, allowable damage limits, and documentation practices. Thus, maintaining this compliance is essential for demonstrating fitness for service and supporting a structured, risk-based integrity management program.

Why Regulatory Compliance for Static Equipment Matters

Static equipment is governed by multiple overlapping regulations. These are designed to ensure the safe design, operation, and inspection of equipment throughout its lifecycle. Regulatory bodies and standards that often apply include:

- API Standards: API 510 (pressure vessel inspection), API 570 (piping), and API 653 (storage tanks) define in-service inspection practices, repair requirements, rerating protocols, and acceptance criteria based on empirical degradation data

- ASME Boiler & Pressure Vessel Code: governs allowable stresses, load cases, and material behaviors for boilers and pressure vessels.

- NFPA 86 (Standard for Ovens and Furnaces): defines requirements for furnaces handling flammable materials or operating in low-oxygen environments, including design, siting, instrumentation, and safety controls.

- OSHA regulations: validates documentation of hazard assessments, inspections, and maintenance.

- NR-13 in Brazil: ensures safe use and oversight of boilers and pressure vessels.

- ISO 17020:2012: sets requirements for inspection bodies, including traceability, impartiality, and record consistency.

Non-compliance can result in legal liability, reputational damage, and, in worst cases, catastrophic failure. But the complexity lies not only in meeting these requirements but in proving compliance, particularly in environments where audits and inspections are frequent, and documentation must be fully traceable.

For instance, in 2011, a catastrophic explosion occurred at a chemical production facility in Louisville, Kentucky, when an electric arc furnace—classified as static equipment—violently overpressured. The incident, which resulted in the deaths of two workers and injuries to others, was traced back to persistent failures in the furnace’s integrity. Despite recurring water leaks, refractory wear, and signs of hazardous overpressure events known as “blows,” the operation continued without implementing a robust inspection or mechanical integrity program. Over two dozen leak repairs had been recorded in just the months leading up to the incident.

Regulatory standards, including NFPA 86 and state safety codes, had established clear guidance for furnaces operating under flammable and low-oxygen conditions. Yet, the absence of enforced safety instrumentation, inadequate maintenance tracking, and the normalization of deviant process conditions ultimately led to tragedy. The explosion not only caused loss of life but also resulted in regulatory penalties and plant disruption, demonstrating how failure to comply with static equipment standards can escalate from overlooked maintenance to irreversible consequences.

Challenges in Ensuring Compliance for Static Equipment

According to an article by Josue Eduardo Franca (2024), several industrial operators are suffering from heavy backlogs due to regulators’ interdictions, with process safety unwanted events in between. And, despite the critical importance of regulatory adherence, maintaining compliance across large and complex industrial facilities presents a range of operational and organizational challenges:

Manual or Fragmented Inspection Processes

Many organizations still rely on spreadsheets, paper forms, or siloed software to plan, conduct, and record inspections. These disconnected tools increase the likelihood of missed inspections, data inconsistencies, and human error, especially under audit pressure.

Traceability and Auditability Gaps

Auditors demand not just inspection results but also traceable evidence: who performed the task, when, under what criteria, and with what tools or instruments. Without accessible traceability, assembling this information retroactively can become a time-consuming, error-prone task.

Lack of Real-Time Visibility

Without centralized tracking and monitoring of inspection status and findings, it’s difficult to proactively address nonconformities or prioritize equipment based on risk. As a result, inspection programs may become reactive, driven by past failures rather than predictive indicators.

Managing Static Equipment Compliance Optimally

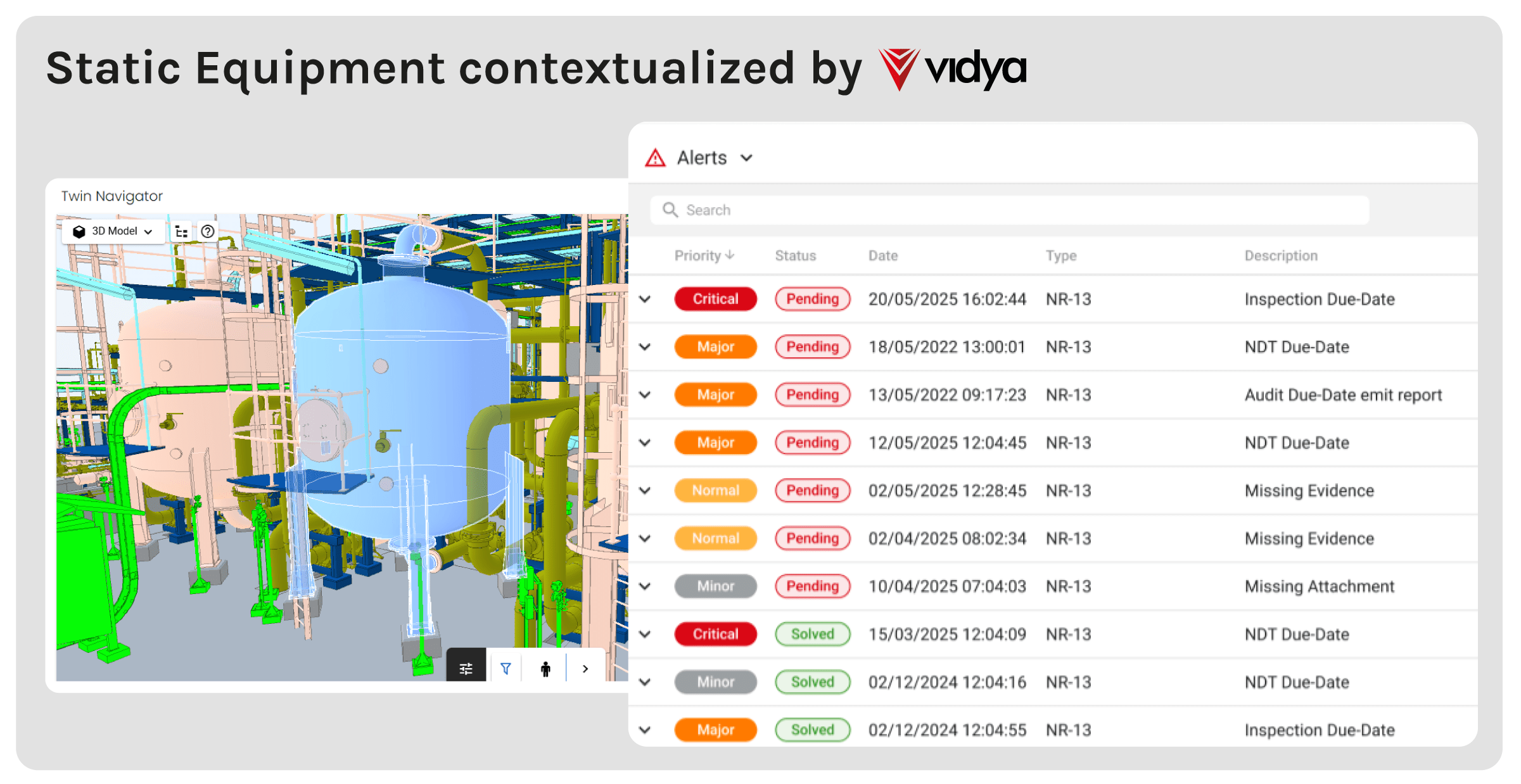

In this scenario, organizations are increasingly turning to digital integrity management systems. And, to navigate the complexities of static equipment regulation, Vidya Technology, a global company in AI-driven Asset Integrity Management for large-process industries, developed a targeted integrity management solution that integrates compliance at the core of operations. With Vidya, you can:

1. Automate Scheduling Based on Equipment Class and Regulation

Vidya’s system helps you map each static asset to its corresponding category and required inspection frequency, as defined by standards like API 510, NR-13, or ASME. Upcoming inspections can be automatically scheduled, with alerts and notifications that ensure no deadline or compliance window is missed.

2. Standardize Field Routines with Regulation-Compliant Checklists

To eliminate inconsistencies and ensure regulatory alignment, Vidya’s system provides digital checklists and workflows fully compliant with the standards that govern each type of equipment. Inspections are executed using pre-configured routines built on API, OSHA, or NR-13 guidelines, reducing interpretation errors and enforcing procedural discipline across the organization.

3. Capture and Centralize Inspection Data

Manual forms and siloed spreadsheets are no longer needed with mobile-enabled workflows. Inspectors can document field activities in real time, attach images and measurement data, classify surface conditions, and flag anomalies. This ensures completeness, accuracy, and traceability of every data point collected.

4. Ensure Full Traceability and ISO 17020:2012 Compliance

Every inspection performed through Vidya’s platform is automatically recorded with time stamps, responsible personnel, procedural references, and supporting evidence. This structure aligns with ISO 17020:2012 traceability and documentation standards, enabling full accountability and rapid audit response with no need to reconstruct records manually.

5. Monitor Compliance Status in Real Time

The platform’s dashboards provide up-to-date visibility into the compliance status of all static equipment assets. Teams can quickly identify overdue inspections, upcoming deadlines, or nonconformities, and take corrective actions before issues escalate. This continuous monitoring capability supports proactive decision-making and risk mitigation.

Conclusion

Effective compliance management for static equipment depends on more than routine inspections; it requires visibility, coordination, and accountability across all layers of operation. With regulatory demands becoming more complex and the consequences of failure more severe, industrial operators need systems that meet the standards and streamline how they are applied. Vidya’s platform was built precisely for this context: integrating standards, automating workflows, and enabling real-time oversight of compliance across entire facilities. In doing so, it supports safer operations, stronger governance, and more efficient asset management in environments where there is no margin for error.