Properly managing risks in the mining industry isn’t a simple task. Inherently, mining activities are characterized by high structural damage, safety risks, and obstructed productivity. Within this volatile environment, companies still face several limitations that impede effective risk management and safety efforts. For this reason, new methods to optimally control hazards need to be explored by the Mining Industry. This article elucidates the industry’s bottlenecks in managing risks and how AI-driven technologies are enhancing current strategies.

Concerns regarding risk management in Mining Industries

According to the European Commission, risk management of a mine or any other mineral extractive facility is a systemic approach that aims to optimize the facility’s overall safety and environmental performance. In this sense, properly mitigating hazards is a major concern even for large industries, but what exactly needs to be mitigated?

1. Diffused data

Mining operations generate gigantic amounts of data, whether structured or not. In addition, each asset has its specific characteristics and safety standards, making data management from various sources a daunting task. In this context, if maintenance teams want to streamline analysis, planning, and decision-making processes, centralizing all equipment data into a unique channel will be necessary.

For this reason, integrating equipment data and operating systems is essential for seamless management. When systems are integrated, data can flow easily between different departments and teams, mitigating hazard chances and reducing the risk of errors. Besides that, by connecting varied sources of information, businesses can trace maintenance reports from multiple areas, giving them a more complete picture of their operations.

2. Safety

Safety represents the most significant concern regarding risk management in the mining industry. Deploying professionals to remote and risky environments involves considerable costs and exposes them to various dangers. Besides that, non-optimized risk management can turn a blind eye to potential fires, explosions, and other accidents, leading to scenarios that could threaten the company’s most valuable asset, its human expertise.

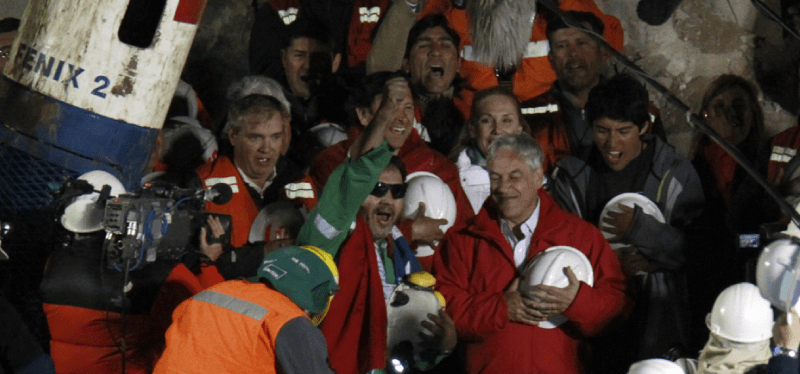

Source: https://g1.globo.com/mundo/fotos/2010/10/resgate-de-mineiros-no-chile.html

For instance, in 2010, a disaster struck a small copper-gold mine in Chile’s Atacama Desert. A tunnel collapse trapped 33 miners 700 meters underground, sparking a global media frenzy and a desperate international rescue effort. For 69 agonizing days, the miners battled claustrophobia, hunger, and dwindling supplies in a makeshift shelter. The tragedy laid bare the mining company’s long history of safety violations, with poor maintenance and shortcuts playing a key role in the disaster.

However, amidst such challenging environments, the support of innovative solutions is building a bright future for the mining industry. These innovations promise not only safer working conditions but also greater sustainability and efficiency. By embracing these advancements and fostering a culture of proactive risk management, the industry can pave the way for safer operations with data-driven insights.

3. Environmental

According to McKinsey, mining is currently responsible for 4 to 7 percent of greenhouse gas (GHG) emissions globally. Regarding this, activities like blasting, hauling, and processing minerals generate CO2 and other pollutants. This scenario requires an attitude change from mining corporations, fostering pollutant emission monitoring and decarbonization strategies. Propelled by the influence of environmental urgency, mining companies are pushed to pursue cleaner and more sustainable practices.

A 2021 Mineral Economics article reports that increasing global demand is pressuring mining companies to implement measures to cut carbon emissions, mitigate climate change effects, and address broader sustainability issues. That being said, it is clear that the high complexity of mining operations requires enhanced maintenance methods to mitigate environmental impacts. Consequently, industries started to seek new eco-friendly methods to conduct maintenance optimally. However, to comprehend current enhanced maintenance methods, it’s necessary to understand how risk is traditionally managed within the Mining Industry.

How is risk traditionally managed within the Mining Industry?

Inherently, mining activities cause structural damage and security risks, unveiling several threats to the equipment, on-site workers, and natural resources. Considering this, these harsh tasks’ effects must be properly managed to mitigate the consequences of actively changing the environment. For this purpose, mining companies traditionally manage risks through inspections based on paper reports.

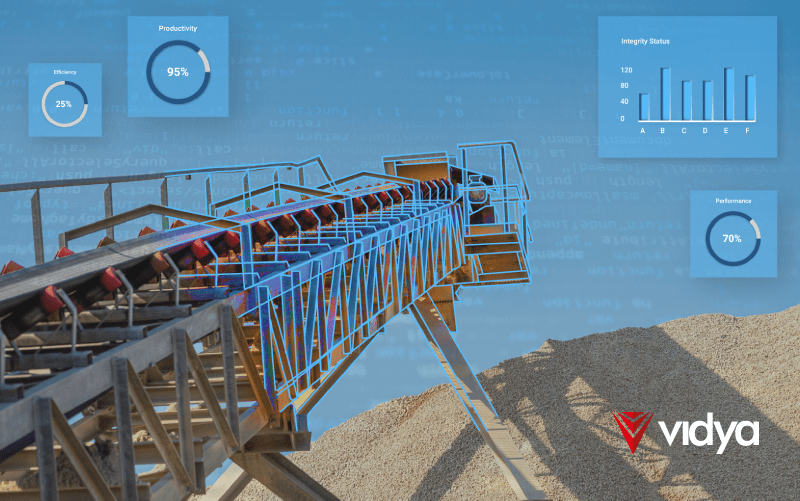

Inspecting and analyzing mining assets such as Conveyors through diffused data sources displays a low capability to visualize problems and possible ramifications. In this context, manually locating and reporting anomalies doesn’t match the massive flow of materials being processed at the same time. Beyond that, these reports take months to be completed, not considering how much it takes to develop and execute a maintenance plan.

Besides that, mine inspections are often done when necessary, and rarely on a scheduled, predictive approach. In this setting, occasional interventions lead to equipment failures and unplanned shutdowns, implicating financial losses and hazards to on-site workers and the environment. In this sense, regularly inspecting facilities holds the potential to prevent shutdowns and eliminate risks.

How is AI enhancing Mining’s risk management?

Mineral extraction represents a naturally extensive process that exposes hundreds of professionals to hazardous environments. For this reason, relying solely on manual reports may not be the best choice for inspecting large mining facilities that process tons of minerals a day. Within this dicey scenario, this irreplaceable human expertise needs to be conciliated with optimal ways of performing asset maintenance.

Indeed, AI technologies such as Computer Vision and Predictive Algorithms come as a solution for mitigating risks and preventing possible errors from becoming harmful outcomes. By freeing workers to execute more well-informed tasks, AI platforms like Vidya provide risk evaluation and prioritization of critical components on field inspections. According to McKinsey, advanced analytics capabilities alongside traditional lean techniques can be used to predict and prevent equipment failures, increase labor productivity, and streamline the management of external contractors.

Beyond that, AI-driven risk management allows operators to broaderly visualize the asset’s conditions, centralizing all equipment data, work orders, and other reports necessary in a unique channel. From this standpoint, this technology indicates the best possible actions considering time constraints, budget, and people on the field limitations, guaranteeing safer, cheaper, and more sustainable inspections. For instance, the Vidya Sofware Platform offers varied applications for enhancing risk management in mining environments:

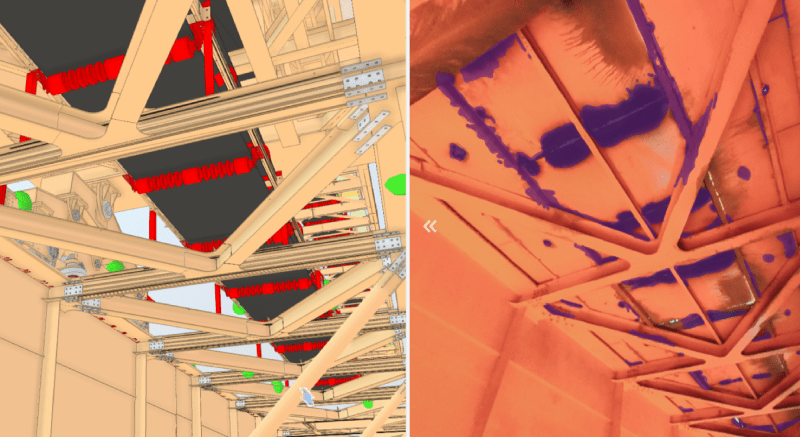

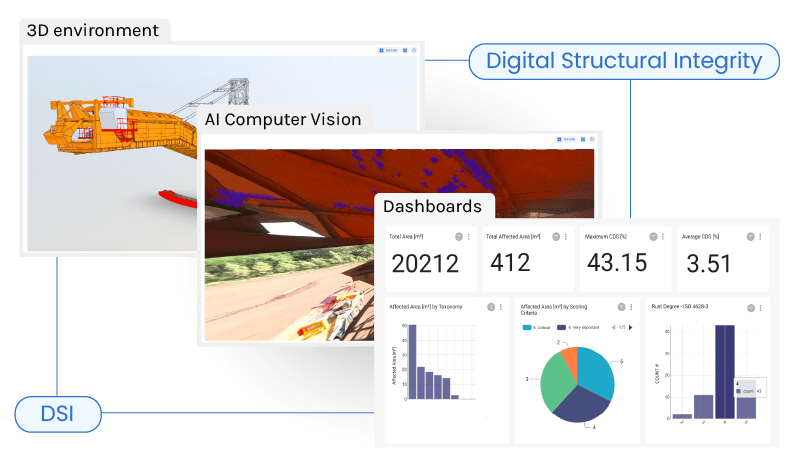

Digital Structural Integrity

The Digital Structural Integrity application autonomously identifies structural anomalies in mining assets. It integrates Artificial Intelligence, 3D environments, and Reality Capture to transform field images into valuable structural integrity outputs, including risk and prioritization matrix, and heatmaps. Additionally, the system performs effectively even in environments characterized by substantial dirtiness. It also analyzes, marks, and identifies structural anomalies and corrosion while strictly adhering to the company’s inspection standards.

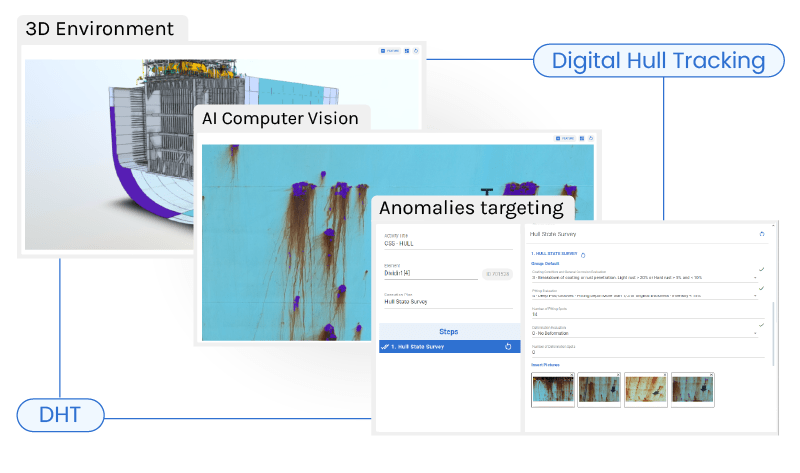

Digital Hull Tracking

Vidya’s Hull Integrity solution is crucial in enhancing bulk carrier integrity. Besides these facilities being inherently exposed to liquefaction, they face hull anomalies such as corrosion, pitting, welding, and other discontinuities. For this purpose, The Digital Hull Tracking application combines reality capture via drone images in a 3D environment with AI to view, locate, classify, and quantify potential discontinuities, pitting, and critical corrosion points. As a result, the application provides a digital and visual management system for hull inspection, with anomalies mapped and classified with maintenance action support and generating integrity notations in less than 30 days.

Conclusion

In essence, the Mining Industries’ inherent and complex risk management challenges are being streamlined with the use of AI. While traditional methods rely on manual inspections based on paper reports, AI brings a paradigm shift by providing a predictive and data-driven approach. As technology continues to advance, the industry stands to benefit from a harmonious integration of human expertise and AI-driven solutions, paving the way for a safer and more efficient future in mineral extraction.