Corrosion detection is a challenging, risky, time-consuming, and expensive process. According to NACE, the global corrosion cost is estimated to be US$2.5 trillion, equivalent to 3.4% of the global GDP (2013). On top of that, it requires workers to inspect every edge of an enormous environment full of flammable hydrocarbons. However, the use of AI is reshaping this practice.

In this context, AI-driven corrosion detection offers a safer and more sustainable method of addressing corrosion by providing a holistic perspective on Asset Integrity Management with 3D models, predictive algorithms, data contextualization, and Machine Learning. Thus, this blog analyzes how AI applies to corrosion treatment and how it supports maintenance routines in the Energy industry.

Traditional Corrosion Detection: How it Works and Its Main Challenges

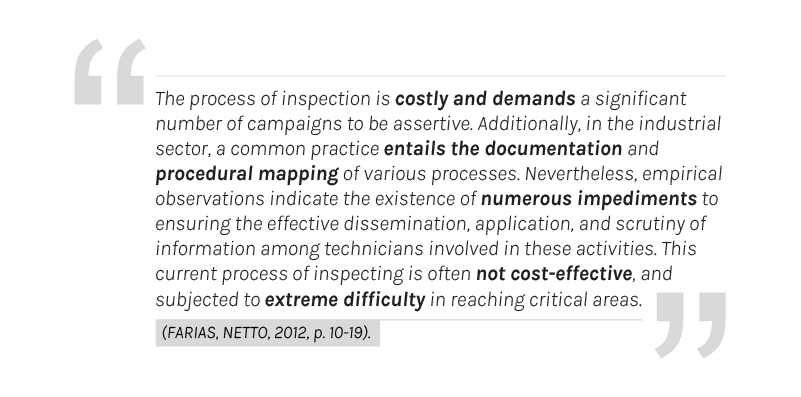

To understand how AI applies to this context, it is necessary to look at how its demand arose. Before AI, corrosion detection alone took months, allocating dozens of professionals in +200.000m² assets to look around for anomalies. Not considering the other stages of corrosion treatment, such as painting, maintenance, and decision-making, which would still take several months to complete.

Corrosion Detection processes must deal with limited time, budget constraints, and costly downtime. Beyond these restrictions generating a time-consuming process, they display a low capability to visualize the problem and its ramifications. In these conditions, a possible anomaly oversight in difficult-to-reach areas may turn into accidents such as oil leaks or explosions. Furthermore, non-optimized inspections consist of monotonous tasks that rely on robust documents for analyzing each asset. Essentially, traditional inspection methods interfere with visualizing improvement points and potential risks optimally.

Limitations on field workers

Addressing corrosion for maintenance involves allocating professionals to inspect an inherently hazardous environment. As a result, companies have to simultaneously deal with limitations on the number of people allowed in the field and the necessity of a specialized workforce to solve occurrences. And, while corrosion progression doesn’t stop, asset activities must be paused to perform mitigation actions.

In this scenario, professionals face multiple challenges related to safety, logistics, technology, and human factors when displaced to industrial operations. It encompasses the remote location of the operation, difficult-to-access areas, dangerous activities that require rope access, unstable weather, and isolation from their families for extended periods. And, while reducing the fieldwork count may appear straightforward, professional intervention remains essential to monitor the asset’s health.

Diffused data

Corrosion inspections also involve relating data from each asset’s components. Each asset has its specific characteristics and safety standards, making data management from various sources daunting. According to Forbes, despite industries collecting vast amounts of data, 60% to 73% of this data has yet to be successfully used for any strategic purpose. Indeed, the Oil and Gas industry relies on an interplay of large-scale equipment and complex procedures, and it is difficult to achieve an assertive maintenance plan with the lack of true awareness regarding historical data.

Additionally, the Journal of Petroleum Technology reported that 80% of employee time in the offshore industry is spent looking through unstructured data to inform decisions. In this sense, maintenance teams consume time relating tons of documents to comprehend the relation and scale of corrosion anomalies. Thus, usual approaches don’t allow a broad visualization of the operation’s improvement points. As industrial organizations build a successful data strategy for their digital transformation plans, they must maintain organizational memory and ensure data has context.

For this reason, corrosion inspections face improvement opportunities, and AI fits perfectly to execute this task.

The role of AI in corrosion detection

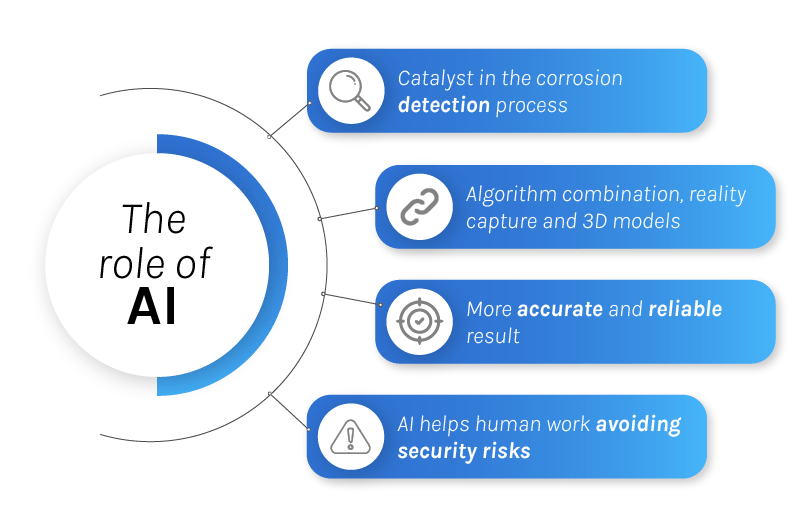

Considering the high complexity and scale of the energy industry’s operations, maintenance inspections needed more efficient and reliable tools to make trackable and auditable Integrity decisions. In this context, AI acts as a catalyst in the corrosion treatment process by unifying all necessary data in a unique channel, providing a holistic analytic framework for Asset Integrity Management.

Thus, by integrating field images into trained algorithms and connecting them to a digital ecosystem, industries can leverage data-driven insights to detect and prevent incidents faster and safer. In this scenario, AI leverages the opportunity to connect different systems and ensures they can communicate and share data seamlessly. The output is to have all the anomalies mapped, classified, and prioritized according to the business rules, supporting engineers in their complex maintenance routines with data-driven insights

Deep Tech Corrosion Treatment: AI Computer Vision

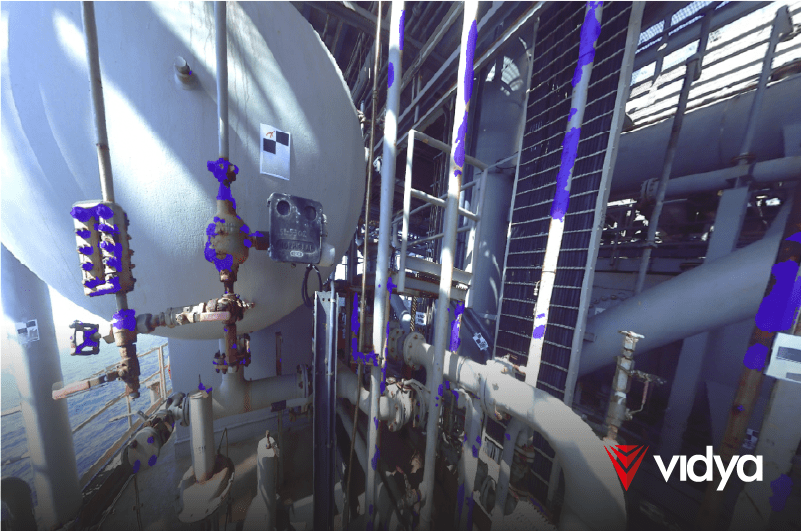

AI Computer Vision was built to detect anomalies optimally, offering enhanced accuracy to extract valuable data and make decisions based on that information. In this regard, this technology trains images to extract the most relevant information for a specific task. This means the system can precisely extract information about the object’s shape, color, and area, facilitating the identification of the established rule.

Computer Vision algorithms enable constant monitoring of an object’s conditions, allowing professionals to determine the anomaly’s scalability and overall impact accurately. Indeed, the use of this technology reduces costs, downtime, and the number of people on the field exposed to inherent risks, foreseeing safer, faster, and more accurate maintenance decisions. This tool marks a paradigm shift in which industries can easily identify minimum and hard-to-reach anomalies and address them before they turn into big problems.

However, Computer Vision alone won’t do the job, the system leverages the essence of any AI, Machine learning. This technology allows the system to learn from its experience, constantly adjusting and improving its behavior. By analyzing massive datasets, Machine Learning algorithms identify patterns and improve their performance over time. Thus, computers can learn from data without needing explicit programming, being able to make predictions, classifications, and relevant alerts.

Conclusion

The integration of AI in corrosion detection marks a transformative shift for the energy industry, enhancing safety, efficiency, and sustainability. By leveraging AI technologies such as Computer Vision and Machine Learning, industries can overcome traditional inspection challenges, reduce costs, and minimize downtime. Certainly, AI-driven solutions offer a comprehensive approach to Asset Integrity Management, enabling real-time monitoring, precise anomaly detection, and data-driven decision-making. This evolution ensures the longevity and reliability of critical infrastructure and paves the way for a more resilient and forward-thinking approach to industrial maintenance and operations.