The International Association of Oil and Gas Producers reported a 36% increase in offshore fatalities from 2020 to 2021. This concerning rise underscores the inherent safety challenges of the industry. Certainly, this sector is subjected to safety threats due to the complex processes and hazardous environments in which it operates. For this reason, high-complexity facilities such as oil and gas need to target safety and risk assessments as fundamental pieces of operational management. But what are the main concerns of the oil and gas industry regarding risk management?

Concerns regarding risk management in the O&G Industry

Classified by the Bureau of Labor Statistics as one of the riskiest industries, oil and gas producers face numerous challenges, including equipment failures, accidents, and safety hazards. In this context, the main objective of the company’s risk management is to ensure the continuity and stability of the production process by preventing threats. Indeed, a single incident can result in dangers to on-site workers, environmental damage, and damage to a company’s reputation. For this reason, it is important to understand the main concerns regarding risk management in the oil and gas industry.

Asset Integrity

Pipelines, storage tanks, offshore platforms, and other structures are all vulnerable to degradation, which results in corrosion, pitting, welding, cracks, and other discontinuities. And, if assets are not adequately protected from these harsh conditions, premature wear and tear can occur. In this scenario, equipment becomes unreliable, leading to more frequent breakdowns, elevated repair costs, and production loss. This implicates risks to the company’s production goals, the environment, and on-site workers.

Operational Safety

Oil and gas operations deal with hazardous materials, demanding environments, and intricate procedures and technologies. For this reason, offshore operations frequently have to manage restrictions on People on Board (POB) numbers, which addresses the most valuable resource companies have, their human expertise. While reducing the POB count may appear straightforward, it is essential to have people on board to ensure the constant monitoring of the asset’s health. In this sense, professional intervention remains essential to the asset’s activities.

Environmental impact

Environmental impact is a top concern. Accidents such as spills or oil leaks can inflict lasting damage on our planet. In this context, offshore operations are often located in ecologically sensitive areas, like the Arctic or deep ocean. For this reason, the industry needs an improved way of dealing with its challenging conditions. Due to this, a robust risk management program acts as an environmental protection, allowing to identify and address environmental risks before they escalate into disasters.

Regulatory compliance

The oil and gas industry operates under a complex web of regulations. In many cases, governments may choose to implement new laws that reduce the profitability or efficiency of oil and gas projects by increasing taxes, reducing subsidies, or establishing new safety procedures. According to the S&P Global Commodity Insights, between 2016 and 2018, an average of 17% of the legal documents maintained in the upstream petroleum database were replaced with newly enacted laws. Within this scenario, industries must adhere to an ever-evolving regulatory framework to stay compliant with regulations.

How is risk traditionally managed within the O&G industry?

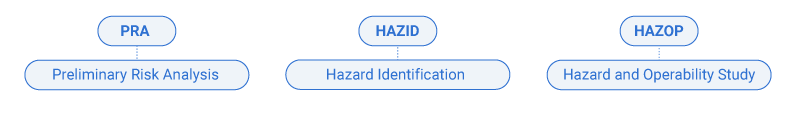

According to Professor Nancy Leveson in MIT Energy Initiative, the offshore oil industry makes it clear that some players in this industry are not using basic and appropriate safety engineering technologies and practices. Naturally, these techniques aim to contribute to risk management, applying safety procedures, regular asset maintenance, risk assessments, and condition monitoring. For instance, several studies such as Preliminary Risk Analysis (PRA), Hazard Identification (HAZID), and Hazard and Operability Study (HAZOP) serve as the foundation for risk management.

General Risk Management Study Structure

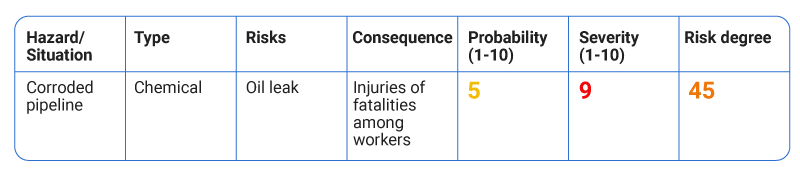

In this context, risk refers to any event or circumstance that can negatively impact the organization’s objectives, whether related to safety, operational efficiency, or environmental protection. These risks are categorized through the mentioned tools to allow mitigation actions in different operational stages. To properly manage and consequently mitigate them, risk-directed studies determine and prioritize risk degrees by classifying them according to the multiplication of the probability of occurrence and severity of each hazard.

*The classification may vary depending on the industry and the applicable laws of the region.

- Hazard / Situation: This is the general term for the occasion that generated the danger or threat;

- Type: Refers to the general nature of the risk;

- Risks: These define what needs to be avoided, it’s the risk itself;

- Consequence: This is the potential outcome of the hazard if it were to occur;

- Probability: This is the likelihood that the hazard will occur. The probability can be expressed as a percentage or a fraction;

- Severity: This is the seriousness of the potential consequences. The severity can be rated on a scale, such as low, medium, or high;

- Risk degree: This represents the overall risk prioritization.

What methodology to choose

Risk analysis can be conducted through varied methods. For this purpose, industries often adopt Preliminary Risk Analysis (PRA), Hazard Identification (HAZID), and Hazard and Operability Study (HAZOP), which have similar structures but different application stages within an operation. In this context, PRAs consist of the simplest tool, providing a holistic analysis of operational risks with risk degree prioritization, essentially following the presented structure. On the other hand, HAZID and HAZOP have proven to be more specialized frameworks by proposing mitigating actions for each situation identified, going beyond the abrasive point-of-view of PRAs.

Besides that, according to the article ‘’Risk Management Techniques HAZOP & HAZID Study’’, both HAZID and HAZOP are group-based analyses utilizing structured guidewords and multidisciplinary inputs to generate risk improvement recommendations. However, HAZIDs are typically conducted early in projects or when risk profiles change significantly, focusing on identifying all hazards and safeguards. At the same time, HAZOPs can be done at any stage, often during mid-design and ongoing operations, requiring more mature design data than HAZID.

Safety Instrumented Systems (SIS)

SIS are essential components of safety risk management in the oil and gas industry. They are independent systems designed to detect and respond to atypical conditions, preventing or mitigating the consequences of potential hazards. SIS are typically used in conjunction with other risk management techniques like HAZOP and PRA to ensure the safety and reliability of operations.

A Safety Instrumented System (SIS) can be configured to protect against various process hazards within a plant by executing one or multiple safety functions. Other common terms for this type of system include safety shutdown system, emergency shutdown system, or safety critical system.

Reliability Centered Maintenance (RCM)

RCM is a systematic approach to maintenance planning that focuses on preventing equipment failures. By analyzing the potential consequences of equipment failures, RCM helps determine the optimal maintenance tasks and intervals to minimize risks and maximize equipment reliability. This approach is crucial for ensuring the safety and efficiency of oil and gas operations.

Elevating Risk Management Analysis

The aforementioned methods allow industries to foster a safety culture, providing causes, effects, and mitigation options for a specific problem into different analytic frameworks. And, although seeming like effective solutions, they involve locating every risk and hazard data analytics on, offshore cases, 200.000m²+ facilities in diffused documents across different datasets. This structure may lead to an extensive process that allocates dozens of professionals in hazardous environments.

In this context, traditional methods display a low capability to visualize the problem and its possible ramifications. Beyond that, these reports take months to be completed, not considering the time it takes to develop and execute a maintenance plan. Despite these being useful tools for safeguarding industrial operations, they still lack the reliability that an AI-integrated safety system delivers. Thus, risk management in the oil and gas industry requires a holistic and comprehensive approach to the complex nature of operations, safety measures, process control, and numerous potential hazards.

Companies that process thousands of barrels of oil can’t afford to expose their operations to these degrading vulnerabilities. Indeed, according to ”WordOil Magazine”, the industry’s complexity, scale of operations, and high cost of production could cause some companies to overlook the benefits of adopting new tools already available. In this regard, traditional risk-oriented studies become a limited framework to analyze the enormous scope of industrial operations, requiring a holistic approach that contemplates hundreds of PDF pages of the mentioned analysis, thousands of variables, and improvement points for each analysis.

How to achieve optimal risk management

Within this dicey scenario, preventing accidents, protecting personnel, and the environment is a top priority for this industry’s risk management. Thus, understanding the status of critical elements, barriers, factors from the preliminary risk analysis and other tools, and information related to Pressure Safety Valves (PSVs) is essential. In these circumstances, platforms such as Vidya support engineers by integrating and visually contextualizing all engineering documents, safety management, shutdown, and turnaround data or procedure

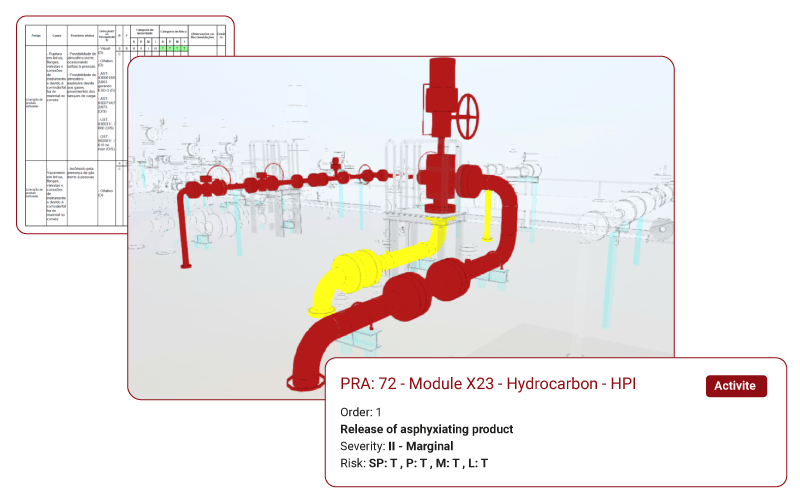

According to The Journal of Petroleum Technology, 80% of employee time in the offshore industry is spent looking through unstructured data to inform decisions. Vidya’s interactive platform represents event chains, allowing users to pinpoint the most likely components to initiate an incident and those most susceptible to its effects. Therefore, instead of looking for hundreds of PDF pages, the risks, sequence of actions, process triggers, causes, effects, and possible failures and hazards are available in a 3D environment with all the scenarios listed and visually animated.

In these conditions, operators can make more data-driven decisions with much more visualization of the asset’s integrity, achieving a holistic point-of-view in risk assessment and emergency preparedness. This technology evaluates the best possible actions considering time constraints, business priorities, and POB limitations, guaranteeing situational awareness, and safer, and more sustainable processes.

Conclusion

Given the urgency of enhancing risk management in the oil and gas industry, traditional methods, while helpful, have limitations due to their time-consuming nature and inability to provide a holistic view of potential problems. However, technological advancements made industries aware of optimal safety management by integrating all engineering documents, safety management, shutdown, and turnaround data or procedures within a 3D environment. This enhanced awareness allows companies to make better-informed decisions, optimize maintenance procedures, and ultimately create a safer and more sustainable future for the oil and gas industry.