In large-process industries, entire facilities operate under conditions of high pressure, high temperature, and elevated risk. Within this context, regulatory compliance is not a bureaucratic obligation—it is a technical imperative. Asset integrity, safety, and operational continuity depend on how well facilities meet and maintain regulatory standards, particularly for pressure-retaining equipment and critical infrastructure. This blog explores why Asset Integrity requires regulatory compliance and how operations can benefit from being transparent and compliant.

Why Asset Integrity Requires Regulatory Compliance

Maintaining the structural integrity of equipment such as pressure vessels, storage tanks, and interconnecting piping systems is essential for mitigating the risk of catastrophic failures. Regulatory frameworks provide the minimum technical requirements for these systems’ design, inspection, maintenance, and operation. In this sense, the requirements are based on the fluid characteristics (toxicity, flammability, operating temperature), equipment classification, and operational pressure-volume profiles.

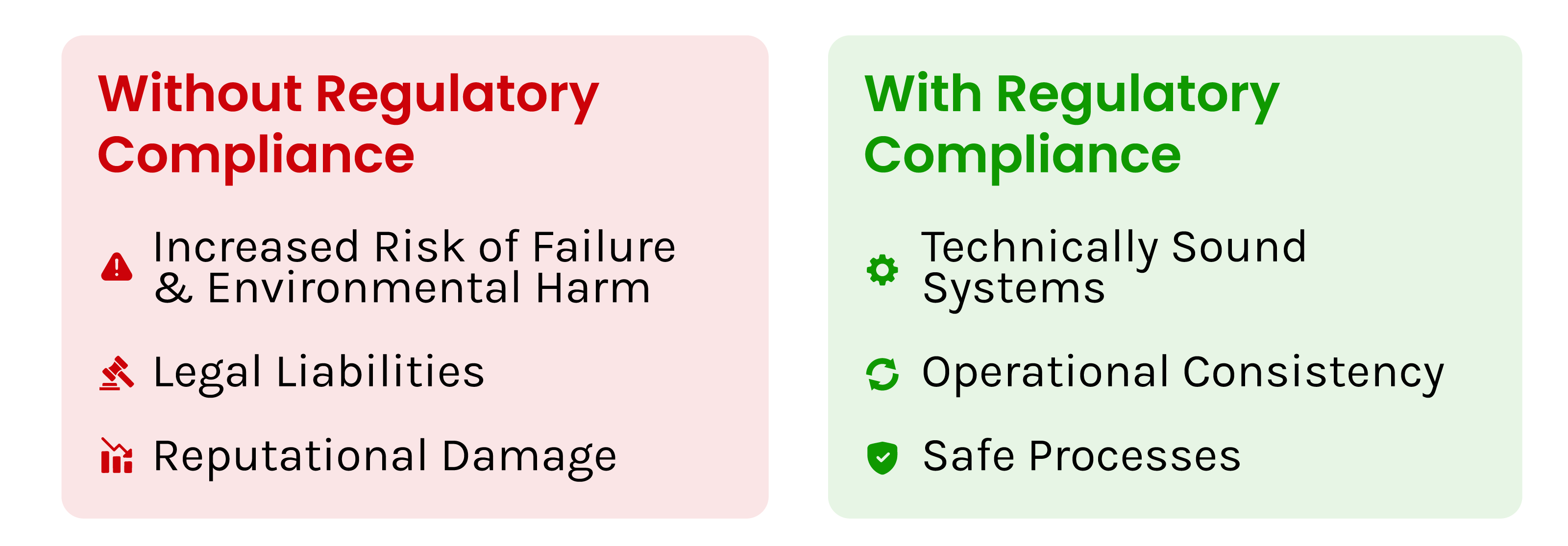

In the absence of compliance, not only is there a higher probability of material failure and environmental impact, but operators also expose themselves to legal liabilities and reputational damage. Regulatory codes ensure that integrity management systems are technically sound and consistent across facilities and operators, providing a reference for safe processes while formally registering how equipment should be handled.

How Regulatory Compliance is Verified in Industrial Facilities

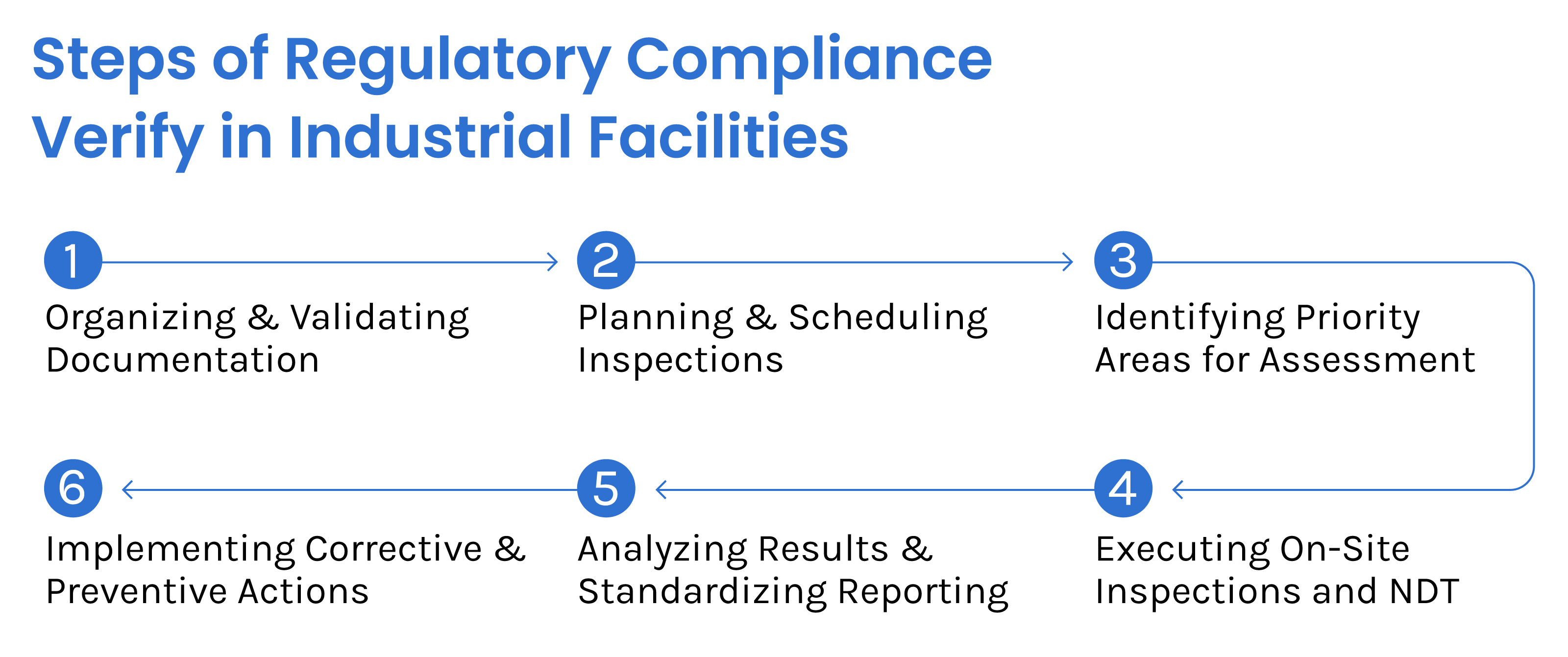

Verifying regulatory compliance in large-process facilities involves a methodical, technically rigorous process. According to Deloitte, only 43% of energy industries conduct an annual compliance assessment, while another 14% infrequently conduct them. The steps below outline the basic procedure typically followed by integrity management teams:

Step 1: Organizing and Validating Documentation

The compliance process begins by consolidating technical documentation related to each pressure-retaining item. This includes design records, fabrication data, inspection histories, operating parameters, and photographic evidence. Ensuring that this information is accurate, complete, and traceable forms the foundation for all subsequent inspection activities.

Step 2: Planning and Scheduling Inspections

With documentation in place, the next step involves establishing inspection timelines based on regulatory requirements and operational risk. This means classifying inspection types—whether initial, periodic, or extraordinary—and defining their frequency according to equipment specifications and service conditions. In these conditions, integrating automated scheduling systems helps prevent missed deadlines while also aligning inspection intervals with asset criticality and degradation behavior.

Step 3: Identifying Priority Areas for Assessment

After establishing the inspection schedule, the next step involves mapping facility assets and determining which equipment presents elevated risk due to operating conditions. By prioritizing components exposed to high pressure, extreme temperatures, corrosive media, or limited accessibility, operations ensure that efforts and resources are directed toward the most critical areas, aligning the inspection scope with real-world vulnerability.

Step 4: Executing On-Site Inspections and NDT

With priority areas defined, inspections can proceed using non-destructive testing (NDT) methods such as ultrasonic thickness gauging and visual examination. These techniques enable the evaluation of structural integrity without disrupting operations, allowing for the detection of wall loss, cracking, or corrosion. Ensuring that inspections are carried out by qualified personnel under established procedures is essential for maintaining technical validity.

Step 5: Analyzing Results and Standardizing Reporting

Following field inspections, the collected data must be analyzed and structured to support regulatory interpretation and future reference. This involves standardizing measurements across equipment classes, validating findings against acceptance criteria, and compiling reports. Beyond that, photographic records, thickness readings, and interpretative comments ensure that the documentation can support audits and guide maintenance decisions.

Step 6: Implementing Corrective and Preventive Actions

Once anomalies have been identified and assessed, the next step involves translating these findings into technically grounded actions. This may include scheduling repairs, replacing components, or initiating detailed engineering evaluations when required. In parallel, using inspection data to estimate the remaining service life of equipment supports more informed maintenance planning. This way, integrity teams guarantee that compliance efforts continuously inform and strengthen the overall asset integrity strategy.

How Industrial Operators Benefit from Regulatory Compliance

Beyond meeting legal mandates, regulatory compliance delivers measurable operational value for industrial facilities managing pressure-retaining equipment. By systematically documenting inspections and aligning maintenance with regulatory frameworks such as OSHA, ASME BPVC, API 510, or NR-13, operators streamline audits, reduce unplanned downtime, and improve the accuracy of life-cycle asset planning.

- OSHA – Occupational Safety and Health Administration: Established by the U.S. Department of Labor in 1971, OSHA is the federal agency responsible for ensuring safe and healthful working conditions across various industries, including energy and manufacturing. OSHA sets and enforces standards for workplace safety, conducts inspections, and provides training, outreach, and assistance to employers and employees.

- ASME Boiler and Pressure Vessel Code (BPVC): Developed by the American Society of Mechanical Engineers, the ASME BPVC is a holistic set of codes that govern the design, fabrication, inspection, and testing of boilers and pressure vessels.

- API 510 – Pressure Vessel Inspection Code: Published by the American Petroleum Institute, API 510 provides guidelines for the in-service inspection, repair, alteration, and rerating of pressure vessels. It is widely used in the oil and gas industry to maintain the mechanical integrity of pressure vessels and ensure they operate safely throughout their service life.

- NR-13 – Brazilian Regulatory Standard: Similar to ASME BPVC, NR-13 is a regulation established by Brazil’s Ministry of Labor, setting forth the minimum requirements for the design, operation, maintenance, and inspection of boilers and pressure vessels. It aims to ensure the structural integrity of such equipment, safeguarding the health and safety of workers in industrial settings.

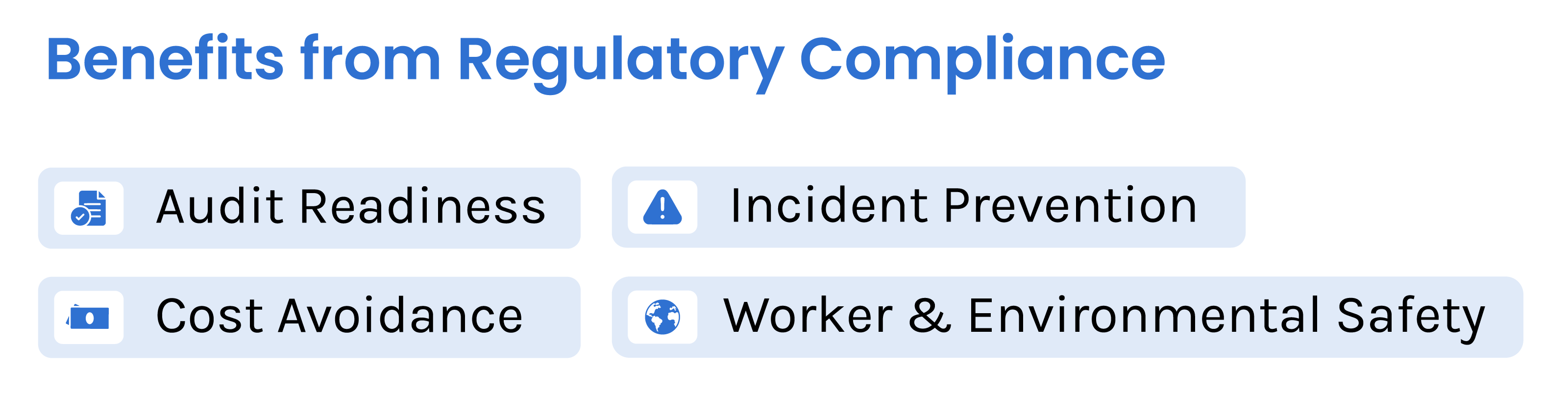

Audit Readiness

A critical benefit of compliance programs is the ease of audit processes. Maintaining organized, digitized records of inspections, tests, and operational history demonstrates adherence to regulations and significantly reduces the administrative burden during data retrieval or third-party inspections. This audit readiness enhances transparency, minimizes disruptions, and positions the operator as a reliable steward of industrial safety.

Incident Prevention

Regulatory compliance requires the consistent evaluation of equipment degradation through precise inspection protocols. A 2022 study by the National Safety Council revealed that companies adhering to updated Occupational Safety and Health Administration (OSHA) guidelines experienced a 25% reduction in workplace accidents compared to prior years. Thus, operators can implement mitigation actions by identifying signs of wear, such as loss of wall thickness or localized corrosion, before they escalate to failure.

Cost Avoidance

While compliance programs require systematic investment, they lead to measurable financial benefits over time. Early detection of mechanical or structural degradation allows operators to avoid unplanned shutdowns, emergency repairs, and extended downtime. The costs associated with reactive maintenance, especially in remote or offshore upstream facilities, are significantly higher than those associated with planned interventions aligned with regulatory schedules.

Worker and Environmental Safety

Ultimately, compliance affirms a company’s commitment to the well-being of its workforce and the surrounding environment. Adhering to technical standards for hazardous equipment reduces the risk of explosions, toxic leaks, and structural failures. This safeguards not only human lives but also critical environmental assets, reinforcing public and regulatory trust in the operator’s risk management culture.

Conclusion

In high-risk industrial environments, regulatory compliance is not simply a checkbox—it is the operational framework through which safety, efficiency, and longevity are achieved. It defines how complex systems should behave under stress, establishes traceable procedures, and sets a technical language for risk control that transcends borders and company boundaries. When industrial operators approach compliance not as an external requirement but as an internal engineering discipline, they unlock a more predictable, auditable, and resilient way of operating. This shift—from compliance as obligation to compliance as strategy—is what ultimately elevates asset integrity from a maintenance routine to a competitive advantage.