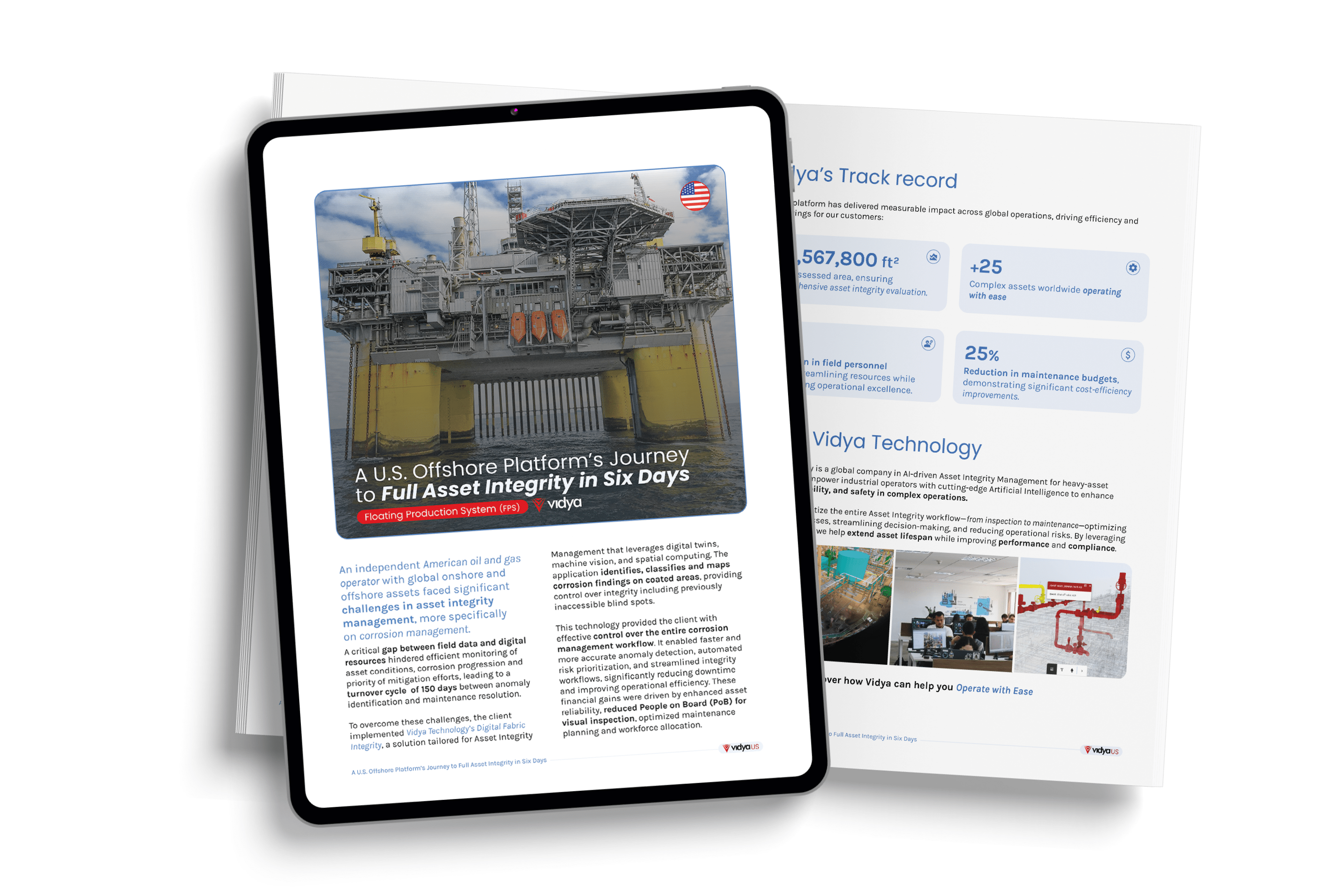

Case Study: A U.S. Offshore Platform’s Journey to Full Asset Integrity in Six Days

Case Study: A U.S. Offshore Platform’s Journey to Full Asset Integrity in Six Days

Executive Summary

An independent American oil and gas operator with a global presence faced significant challenges in asset integrity management. Disconnected data sources and manual inspection workflows led to 150-day cycles between anomaly detection and resolution, leading to operational inefficiencies, increased costs, and heightened risk.

By implementing Vidya’s Digital Fabric Integrity (DFI) solution, the client achieved comprehensive visibility over the asset’s condition, including previously inaccessible areas. The platform enabled anomaly detection, automated risk prioritization, and streamlined workflows. The outcomes included enhanced asset reliability, reduced personnel on board (PoB) for inspections, and significant improvements in time and cost efficiency.

The Challenge

Operating in complex offshore environments, the client encountered several obstacles:

These challenges hindered maintenance planning, increased backlog, and inflated costs.

The Solution: Digital Fabric Integrity

Vidya’s Digital Fabric Integrity integrates digital twins, machine vision, and spatial computing to provide a centralized asset integrity environment. Key functionalities include: