Digital Twins: More Than

Just a Buzzword

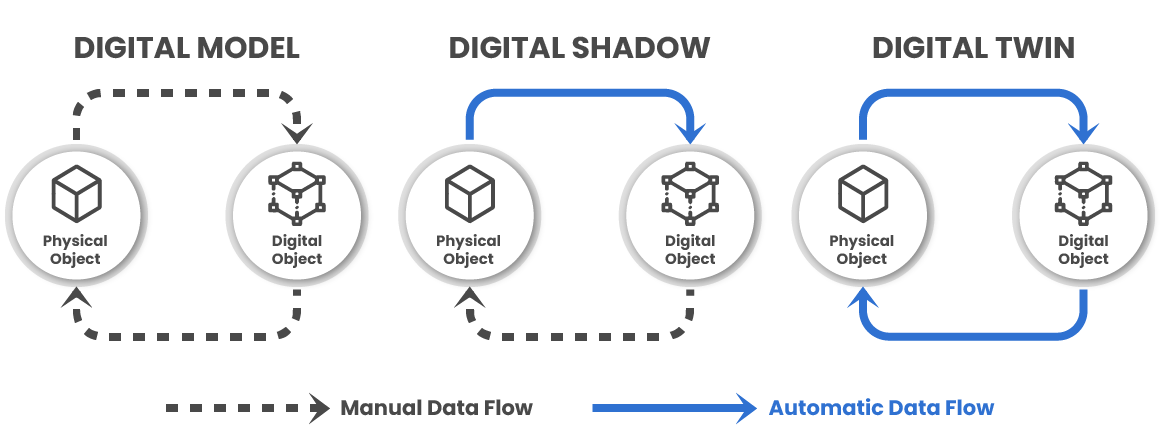

Digital twins have gained popularity in many industries. While some may claim to have digital twins, the reality is that not all implementations fully capture the concept.

At Vidya, we’ve been at the forefront of this technology for over a decade. Our expertise is tailoring digital twins to specific client needs, ensuring optimal operational adherence. With multiple use cases in asset integrity and performance management, we’ve proven the transformative power of this technology.

The Digital Twin: A Revolutionary Concept

Originally conceived by Michael Grieves in 2002 for Project Lifecycle Management (PLM), the digital twin has evolved into a versatile technology with applications extending far beyond its initial scope. While it remains a cornerstone of PLM, businesses across various industries have recognized its potential to streamline processes and enhance operations.

Why Digital Twins have failed in the past

Despite the growing interest, the widespread adoption of digital twins has been hindered by factors such as:

Industrial Digital Twins: Vidya’s Approach

The term “digital twin” has become somewhat oversaturated and even met with disinterest.

Many believe a digital twin is simply a digital representation or data dump, failing to grasp its full potential.

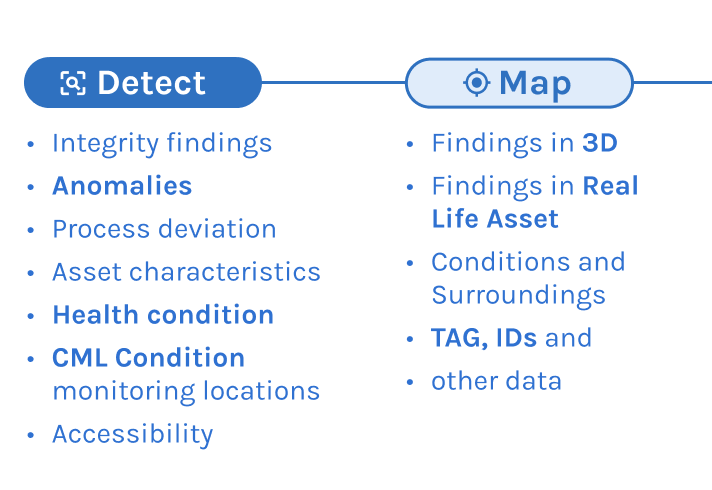

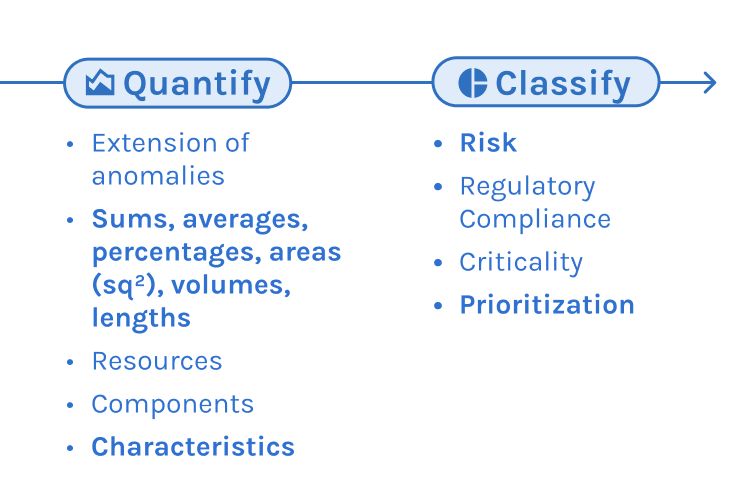

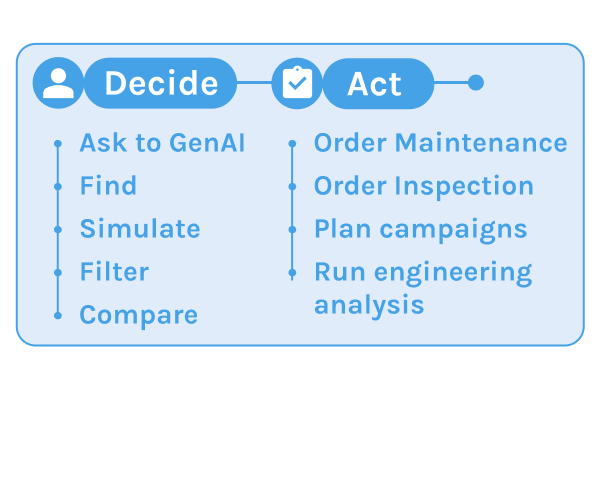

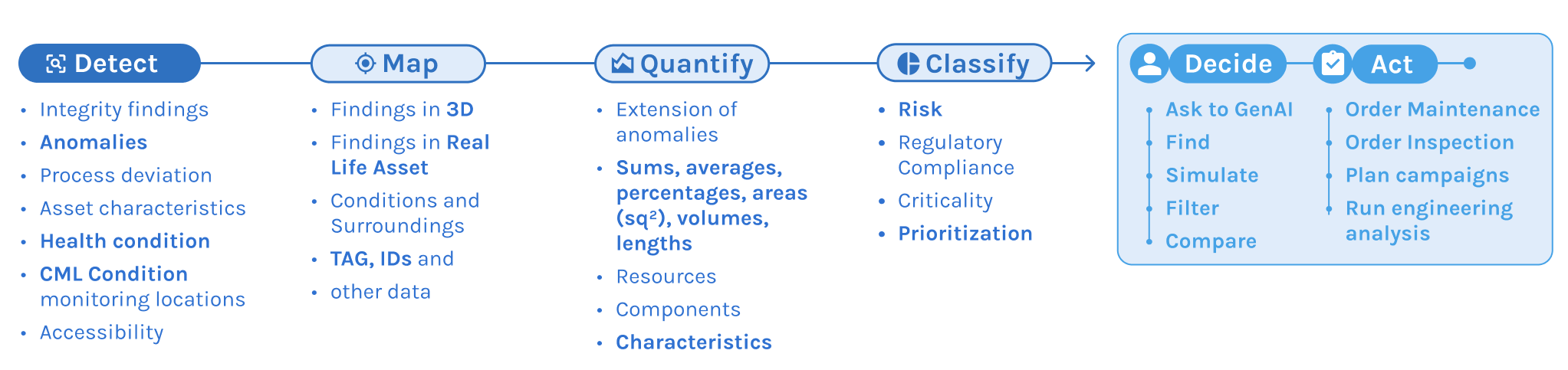

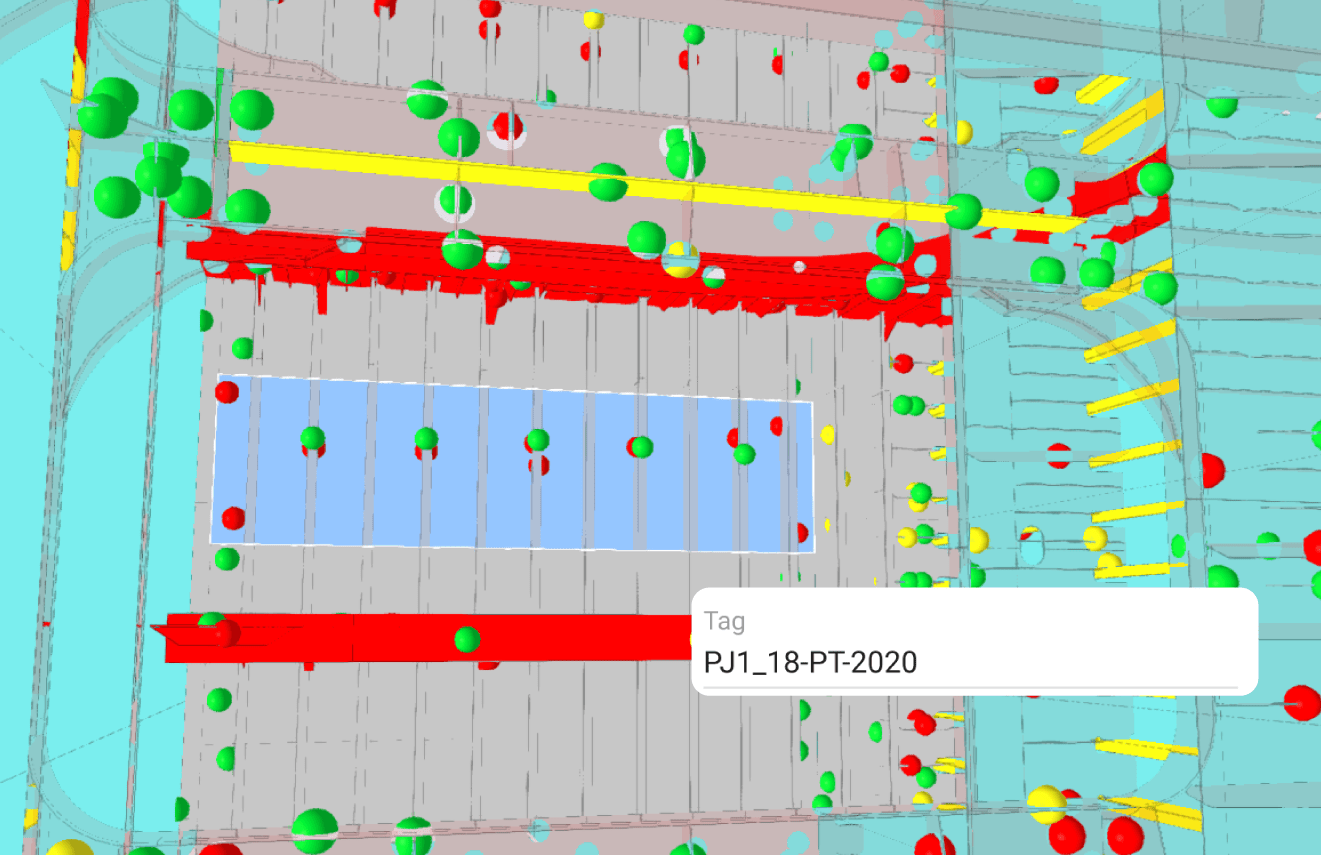

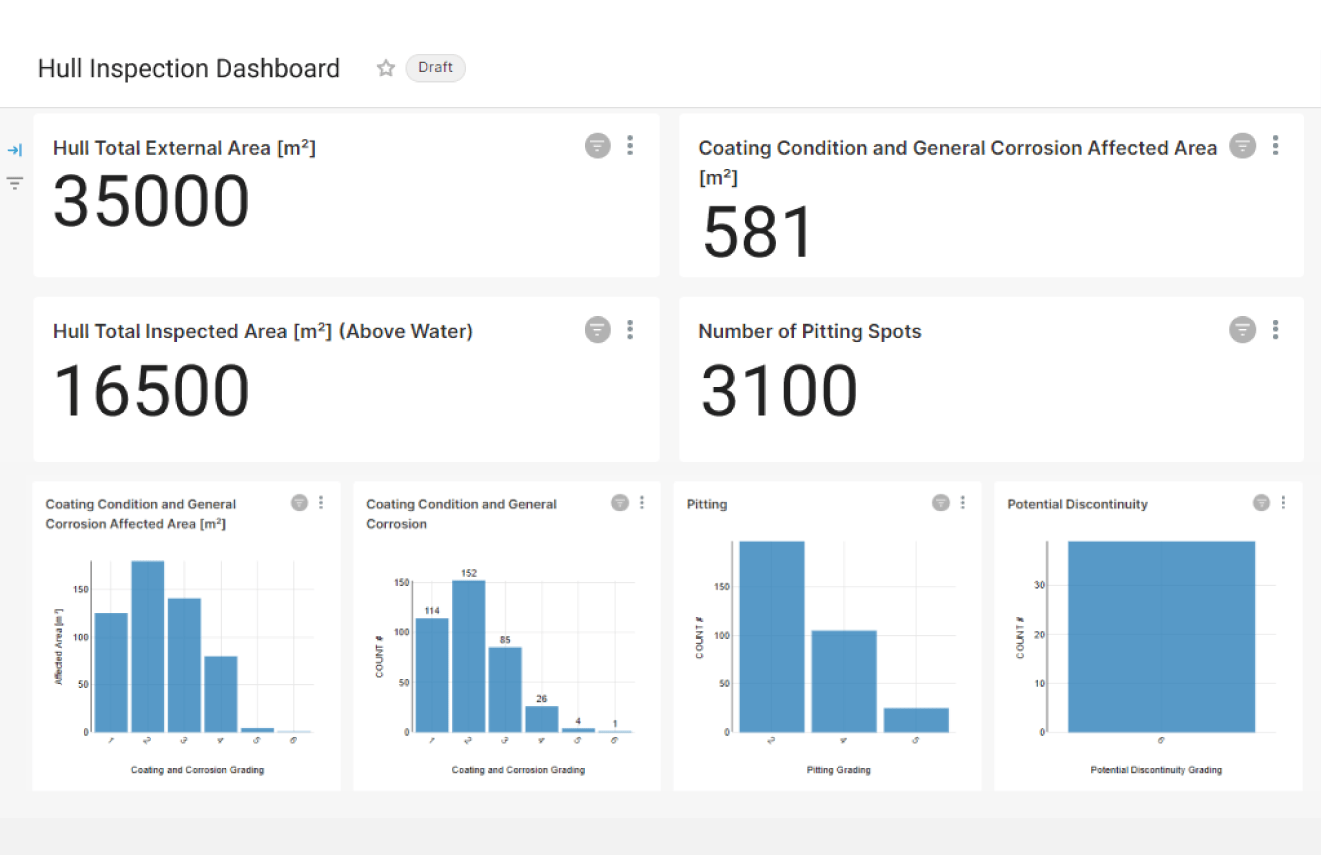

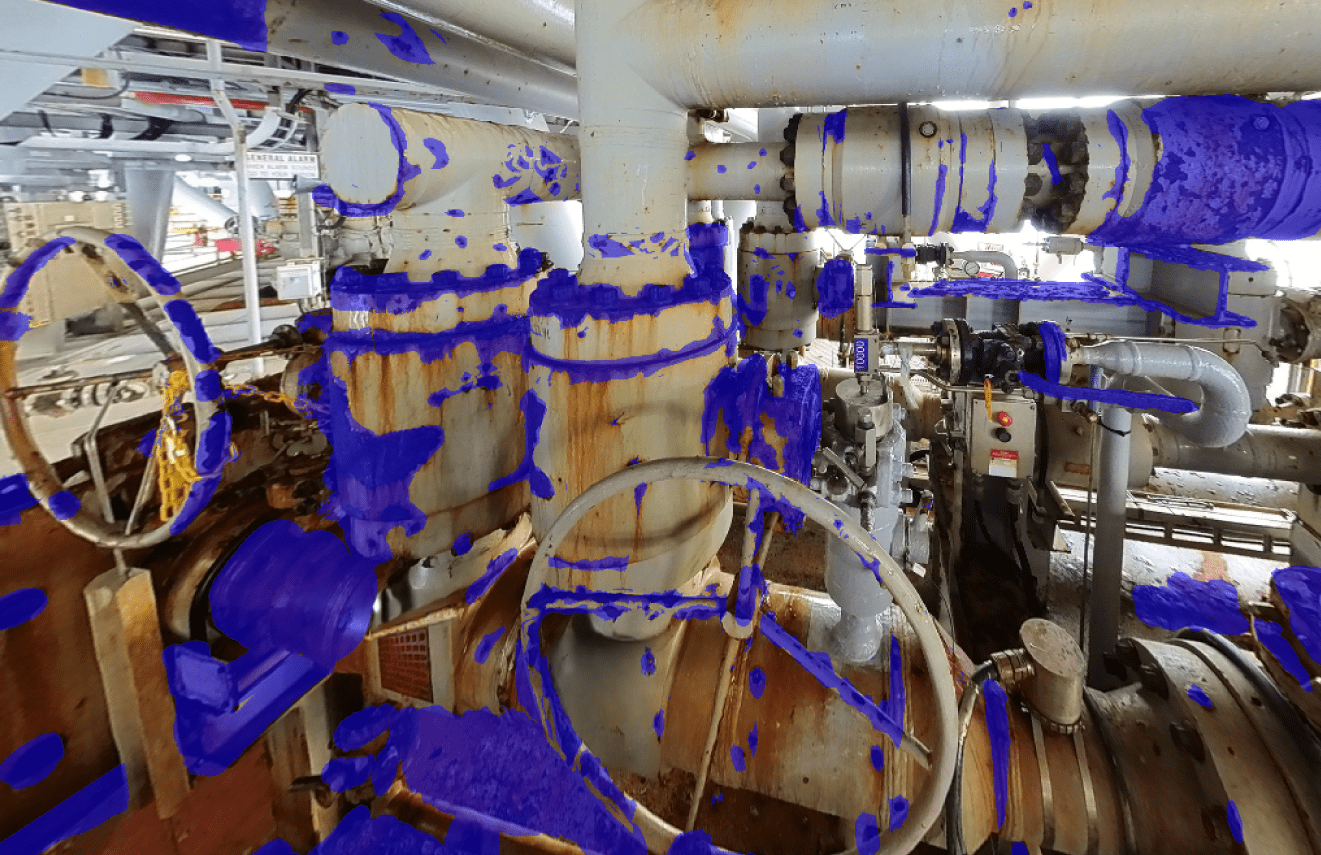

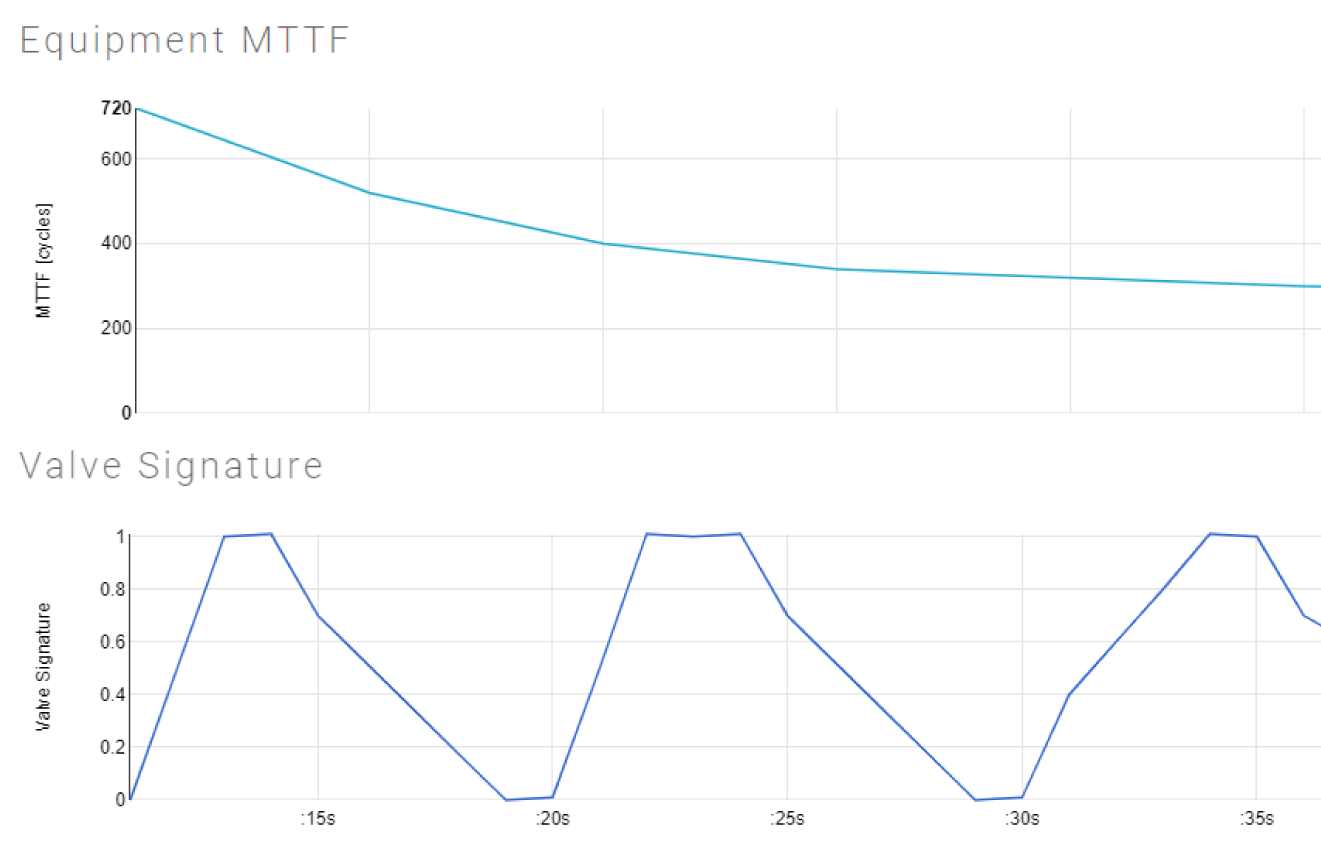

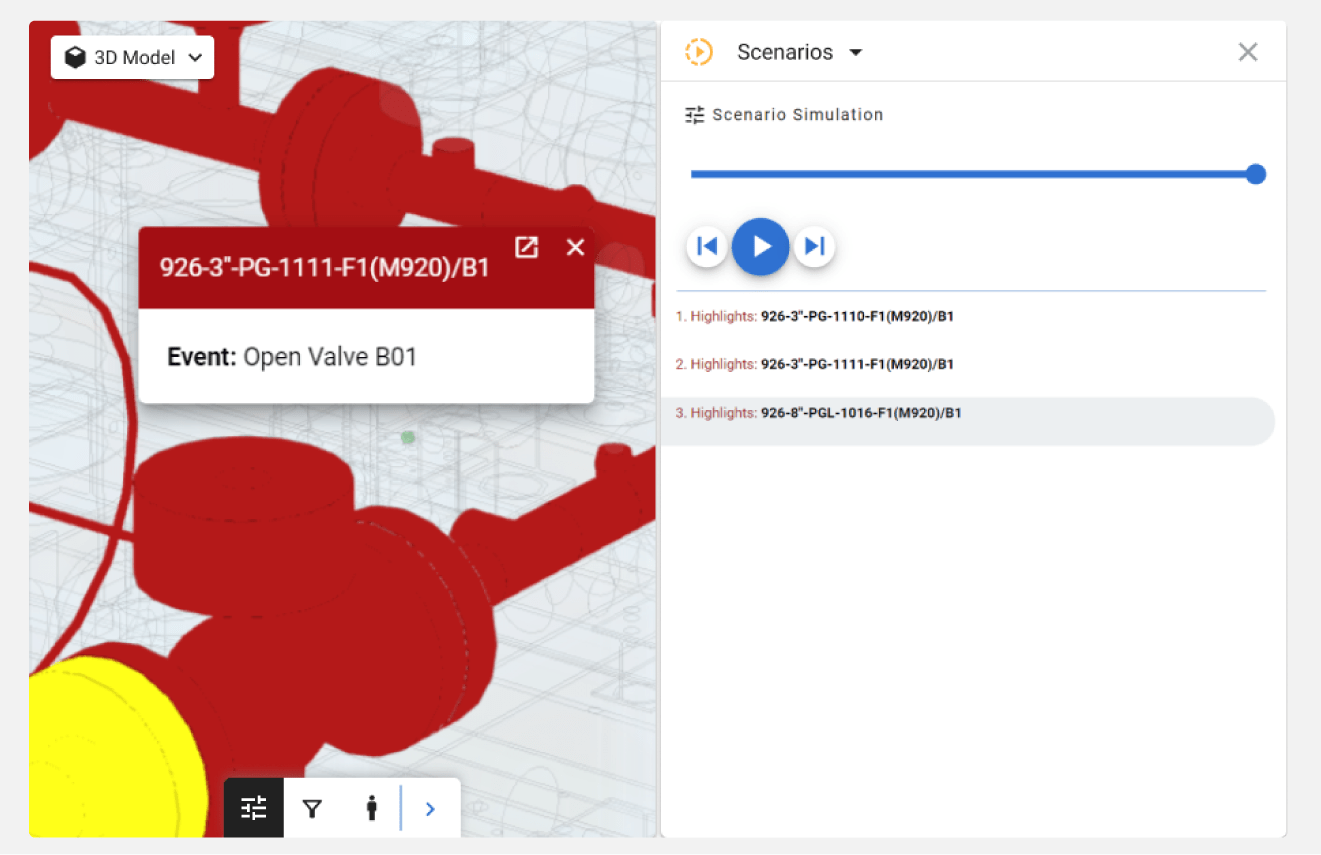

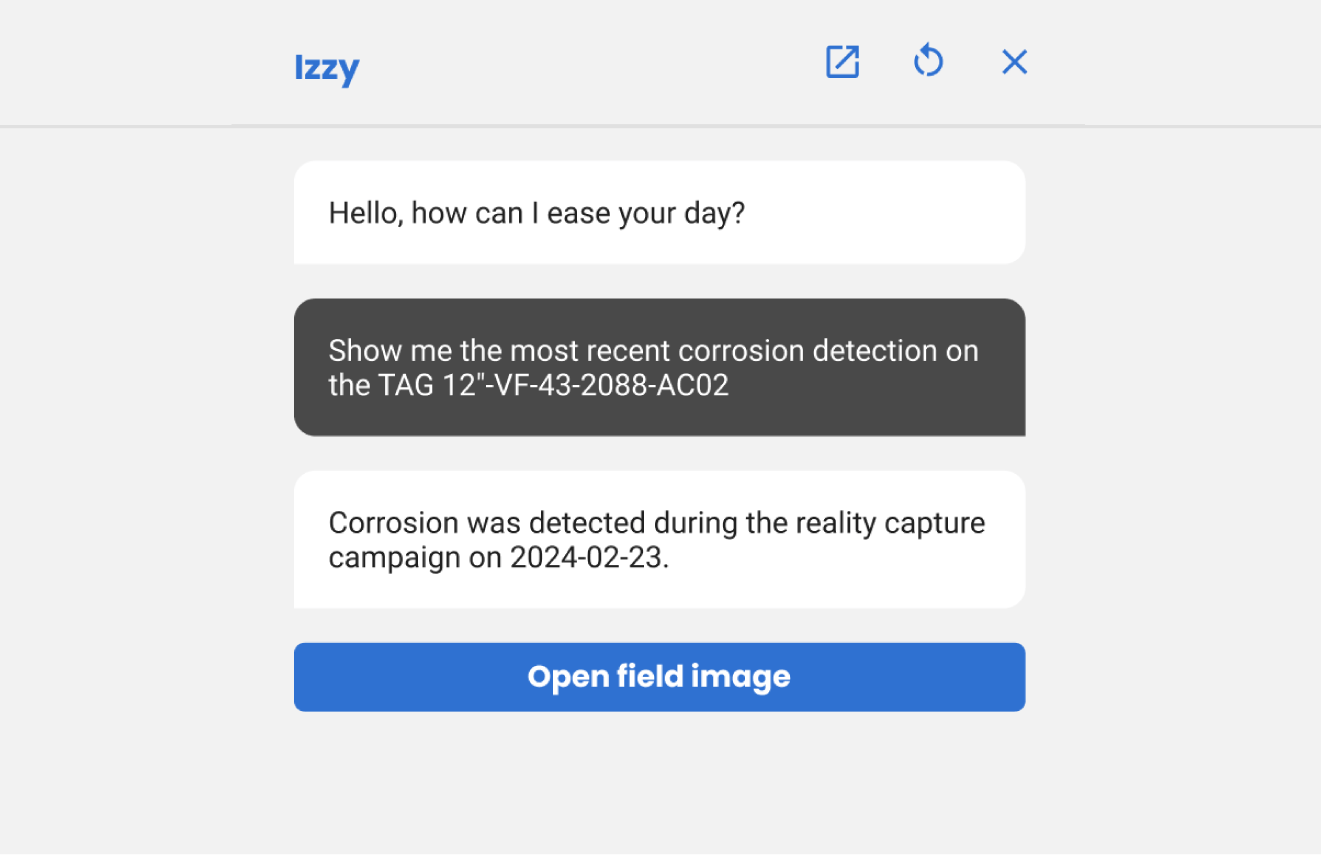

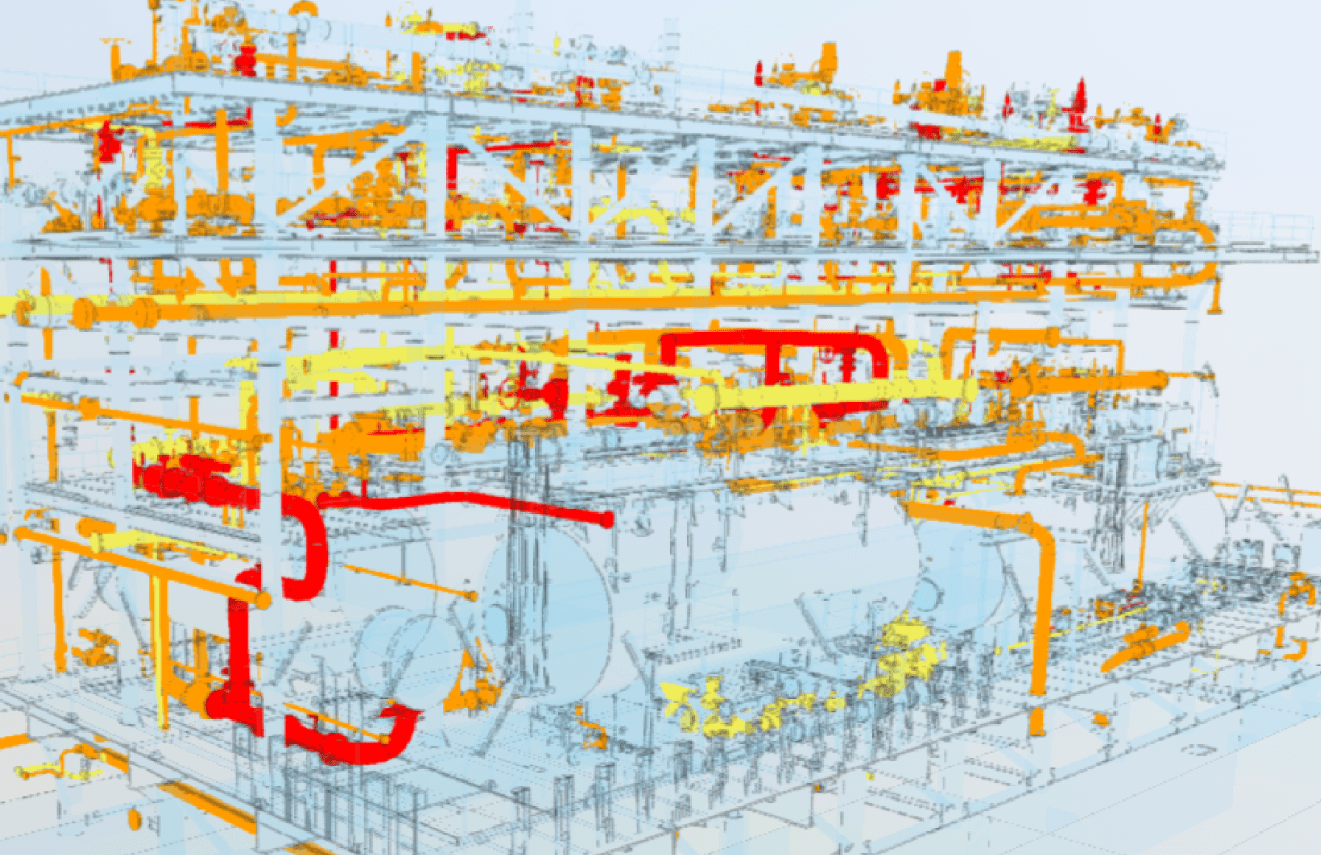

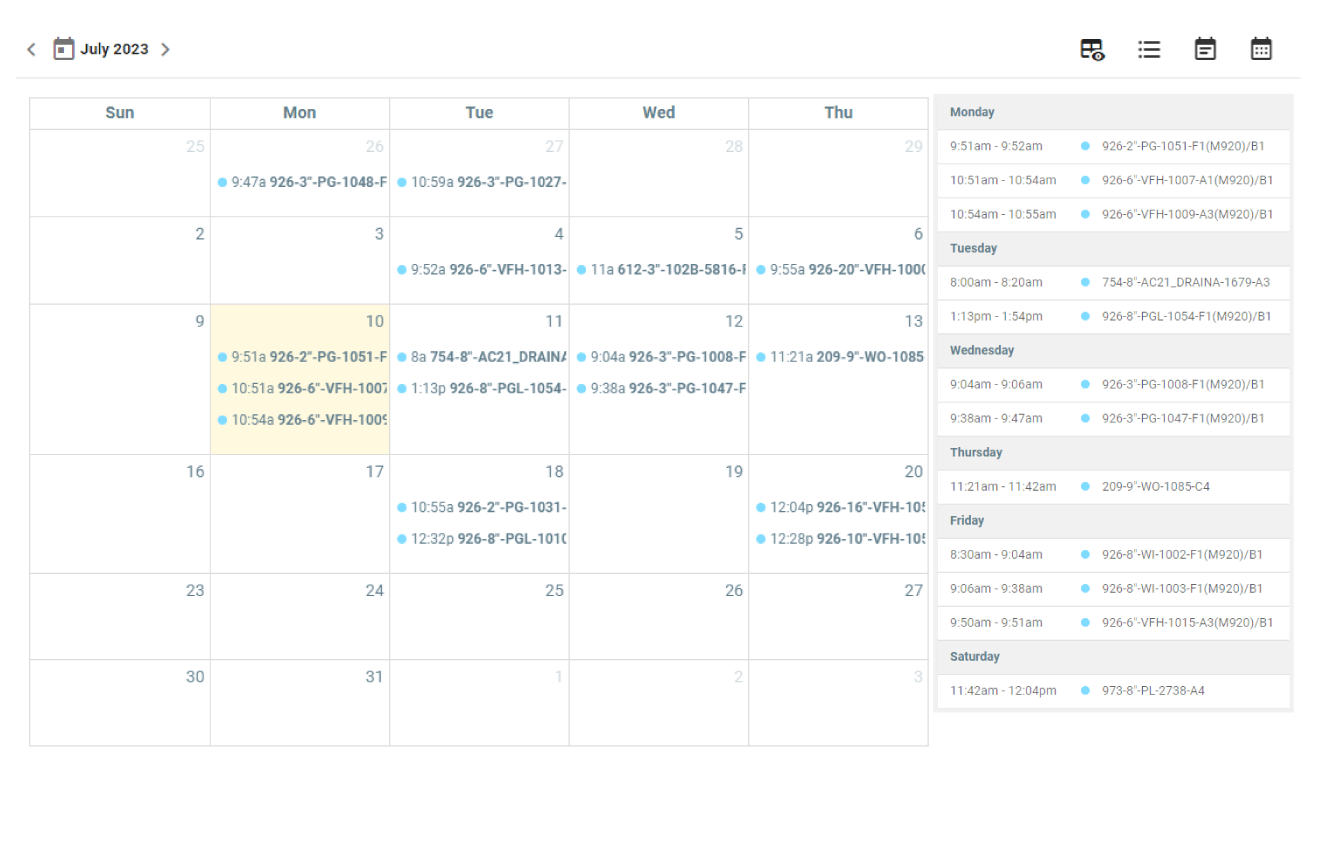

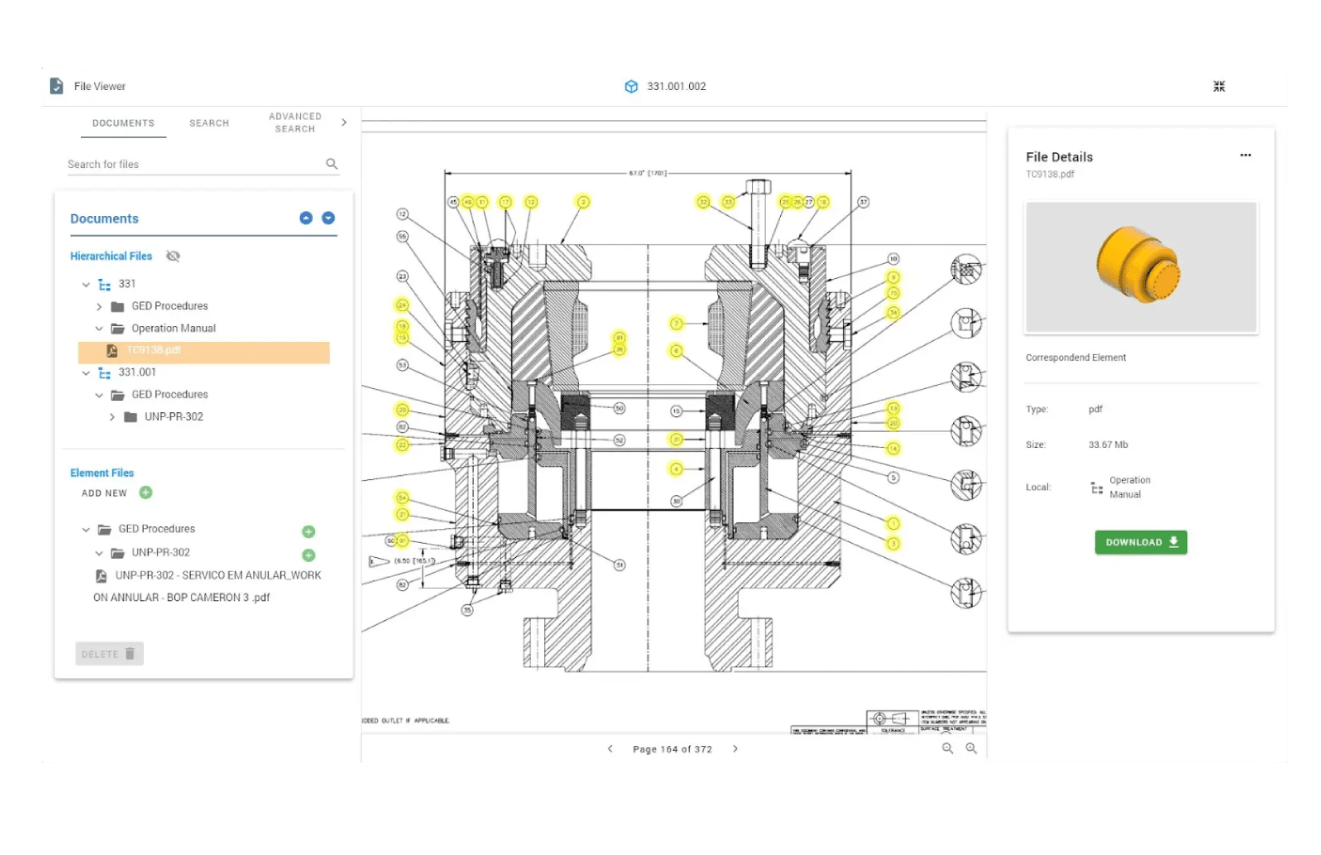

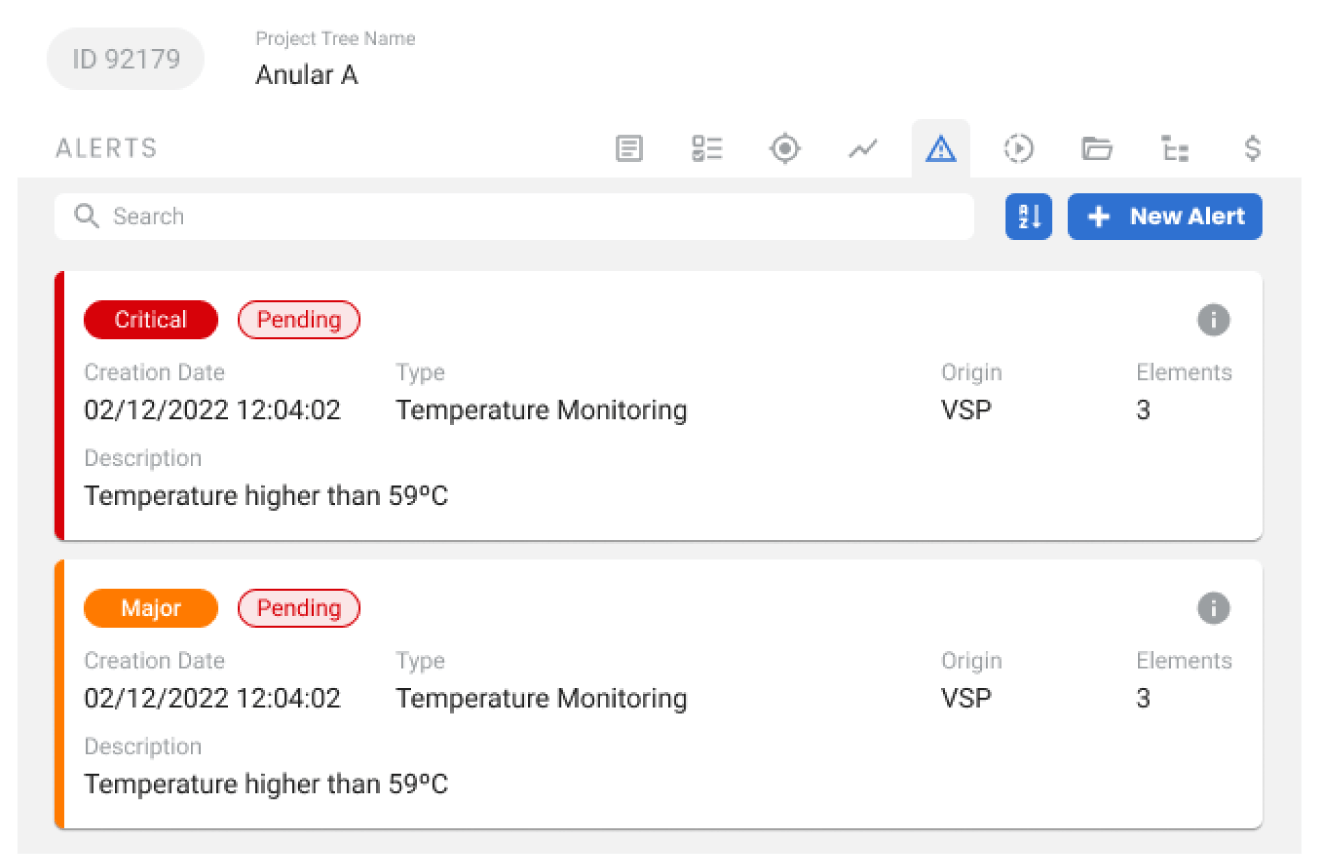

It empowers users to go beyond viewing reality capture data, offering a deep understanding of spatial information and business processes. By infusing artificial intelligence, and simulation, managers can predict and support integrity and performance routines.

This comprehensive spatial context, integrated with Digital Twin, enables the system to identify existing asset conditions. Users can easily view and share any data from any source, and access enhanced resolution of reality data with a semantic relationship.

Vidya’s spatial computing approach empowers organizations to unlock the full potential of their assets. By leveraging AI and advanced spatial technologies, users can establish accurate information directly from assets in the field, including asset tags, documentation, and condition assessments.

Vidya’s Awards

Vidya has a history of innovation that’s changed the industry. We’re dedicated to staying ahead of the curve and pushing the boundaries of technology.

Vidya’s Awards

Vidya has a history of innovation that’s changed the industry.

We’re dedicated to staying ahead of the curve and pushing the boundaries of technology.

See Vidya’s Digital Twin in action

At Vidya Technology, we’re passionate about helping businesses achieve real-world results through the power of Artificial Intelligence, Digital Twins and Asset Performance Management (APM). Whether you’re facing challenges in the upstream, marine, or mining sector, our team of specialists is here to listen and develop a customized solution.

Beyond a digital solution, we deliver a digital twin in 30 days. By completing the forms we can:

- Showcase our technology: Discover how we can build you a digital twin to support your challenges, saving you valuable time and resources.

- Demonstrate real-world results: See firsthand the impact we’ve achieved for similar companies facing the same challenges.

- Craft a pilot plan: We’ll work together to identify how our solution can specifically address your needs.

- Understand your challenges: We’ll listen closely to your top concerns and the current challenges you’re facing.