Vidya will present two technical articles regarding our deeptech solutions at ROGe 2024. The second presentation, which takes place on September 23rd, will discuss the Digital Fabric Maintenance application. The article showcases the application’s tracked and proven impact on the oil and gas industry. Get to know our article better in this blogpost:

”A case study of an alternative approach to digitize the management of external corrosion and fabric maintenance workflow of an offshore installation”

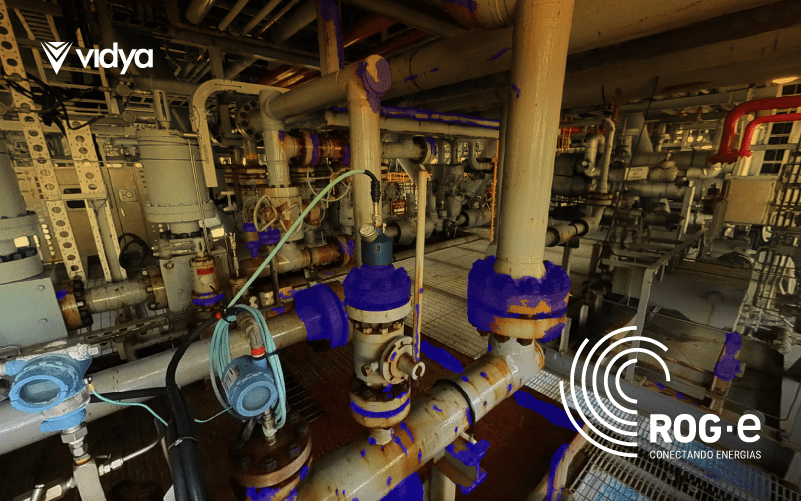

Corrosion poses a significant and inherent threat to the Oil and Gas industry, leading to equipment failure and production losses. For this purpose, corrosion control strategies address situations where corrosion has already begun, aiming to slow down the ongoing degradation. Therefore, a common control method involves isolating the metallic substrate from the corrosive environment using protective coatings. However, at some point, coatings will be subject to error, demanding maintenance professionals to intervene at an early stage.

And, despite the crucial role of integrity professionals in outlining standardized inspection processes that consider degradation mechanisms, failure modes, and operational criticality, current practices often lack integration between these vital processes and sources of information. This fragmentation creates significant challenges for those responsible for the asset’s integrity and structural maintenance during operation. Corrosive atmospheres, diverse painting systems, and an extensive total of painted areas all contribute to the complexity of managing this critical aspect of asset health. Consequently, substantial resources are necessary to ensure effective paint maintenance.

In light of these challenges, Vidya developed a solution to digitize the entire fabric maintenance workflow, encompassing inspection, data management, and maintenance execution. The result of the project consists of a cloud-based platform that contextualizes field images and integrity data into trained algorithms to autonomously identify anomalies such as pitting, welding, potential discontinuities, and corrosion using Deep Neural Networks. Thus, the system analyzes the historical performance data of machines to forecast when one is likely to fail, limit the time it is out of service, and identify the root cause of the problem.

Special Invite: ROGe presentation

If you’re interested in learning more about this technology, our team will have an exclusive presentation about the Digital Fabric Maintenance application on September 23rd at ROGe 2024, which takes place on the Olympic Boulevard, Rio de Janeiro, 23 – 26 September 2024. ROGe, the largest conference in the sector in Latin America, reunites global industry leaders to share ideas and innovations and to discuss the energy sector’s most pressing challenges. Join us.

You can learn more at: https://www.roge.energy/