Production continuity is the gold standard in oil and gas operations, but it’s not always the best path to long-term efficiency, safety, or profitability. At some point in the lifecycle of every industrial asset, stopping becomes necessary. Shutdowns and turnarounds are moments of strategic pause that allow for essential maintenance, inspections, upgrades, and planning for the future. Far from being interruptions, these events are critical for operational excellence.

Why Shutdowns Happen

Shutdowns are usually driven by the need to preserve asset integrity, meet regulatory requirements, or integrate improvements. Over time, even the most robust equipment wears down, and operating conditions can change in ways that compromise efficiency or safety. Sometimes, inspections reveal early-stage degradation that must be addressed to avoid failures. In other cases, regulatory standards require specific intervals for inspections, certifications, or upgrades. Thus, planning a shutdown becomes the responsible course of action, not just to comply with standards, but to manage risks and protect production in the long run proactively.

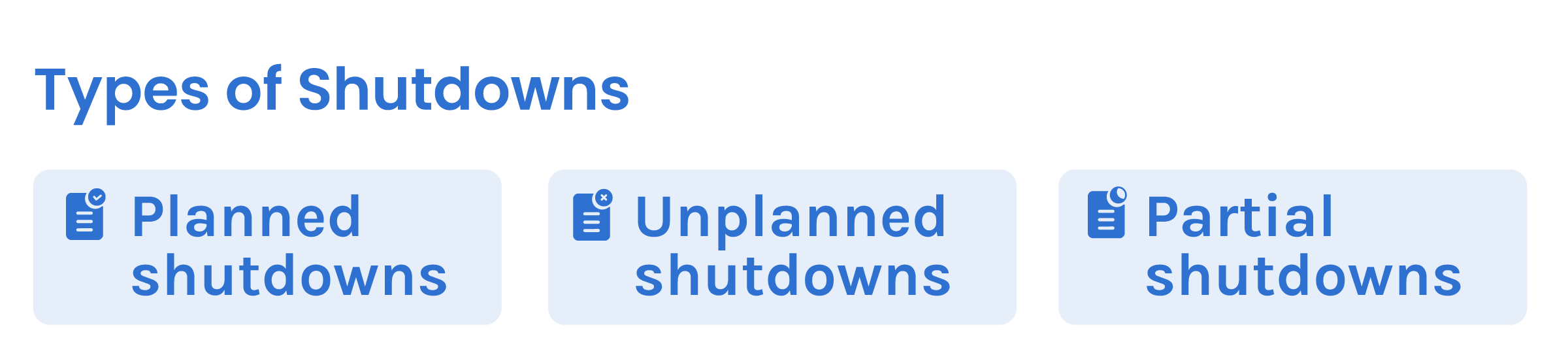

Understanding the Types of Shutdowns

Although“shutdown” may sound straightforward, it encompasses different operational stoppages, each with its own context.

- Planned shutdowns are pre-scheduled and scoped out in advance, often aligning with production cycles or regulatory inspection timelines. They focus on maintenance, safety checks, and equipment upgrades, and are usually carried out every few years, depending on the facility.

- Unplanned shutdowns, however, are reactive. They are emergency responses to equipment failure, safety incidents, or unexpected regulatory issues. They are costly, chaotic, and ideally avoided through good planning and monitoring.

- Partial shutdowns are limited in scope, isolating a specific unit or section of the facility, allowing the rest of the operation to continue. These are often used when localized maintenance is needed.

- Then there are turnarounds, which go beyond standard shutdowns, in both scale and complexity.

What Makes a Turnaround Different?

Turnarounds (or TARs) are comprehensive, facility-wide events that involve taking the entire plant offline. While a shutdown might last days, a turnaround often spans weeks or even months, depending on the asset’s size and the scope of work. These are rare and strategic, usually taking place every 4 to 10 years.

Turnarounds perform deep maintenance, execute major overhauls, replace critical systems, and even implement capital projects that can’t be executed during regular operation. Because of their scale, they require significantly more planning, coordination, and resources. They also represent a substantial financial commitment, with costs that can run into the tens or hundreds of millions.

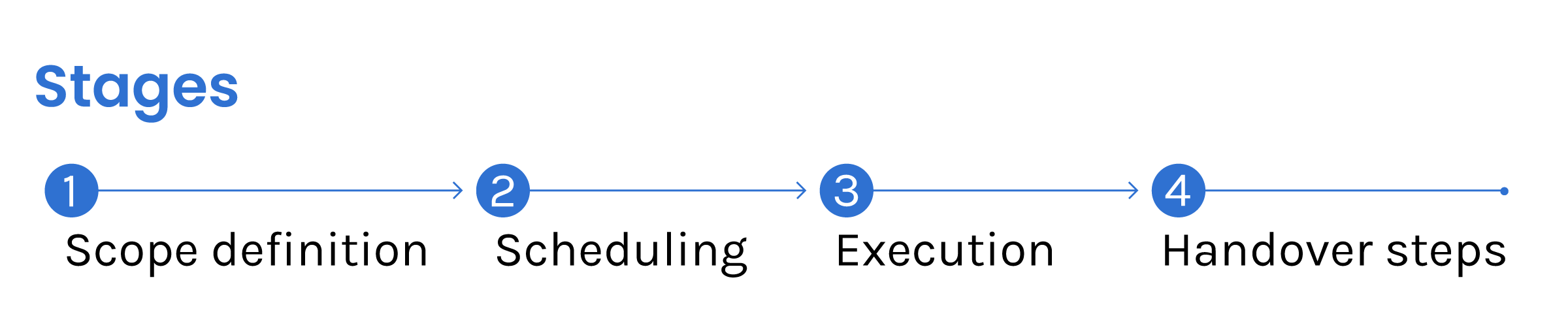

Planning and Executing Shutdowns and Turnarounds

Both shutdowns and turnarounds follow structured stages, beginning with scope definition. Here, planners determine which equipment or systems need inspection, repair, or replacement. This step requires detailed technical input, accurate asset data, and a strong understanding of risk. Then comes scheduling, where the event’s timing is aligned with operational calendars, market demand, and contractor availability.

Execution is a phase where the risks rise significantly. Teams from multiple disciplines—maintenance, engineering, HSE, operations—converge on the site, often joined by hundreds of third-party contractors. Safety protocols must be reinforced, logistics closely managed, and timelines tightly tracked. Finally, the Turnaround cycle is wrapped with start-up and handover steps: bringing the facility back online requires controlled ramp-up, testing, and verification of all systems to ensure a safe return to production.

In this context, digital technologies have become essential during these processes. From asset performance management systems to digital twins, data analytics, and integrated planning platforms, companies are increasingly relying on technology to model scenarios, track real-time progress, and prevent costly delays.

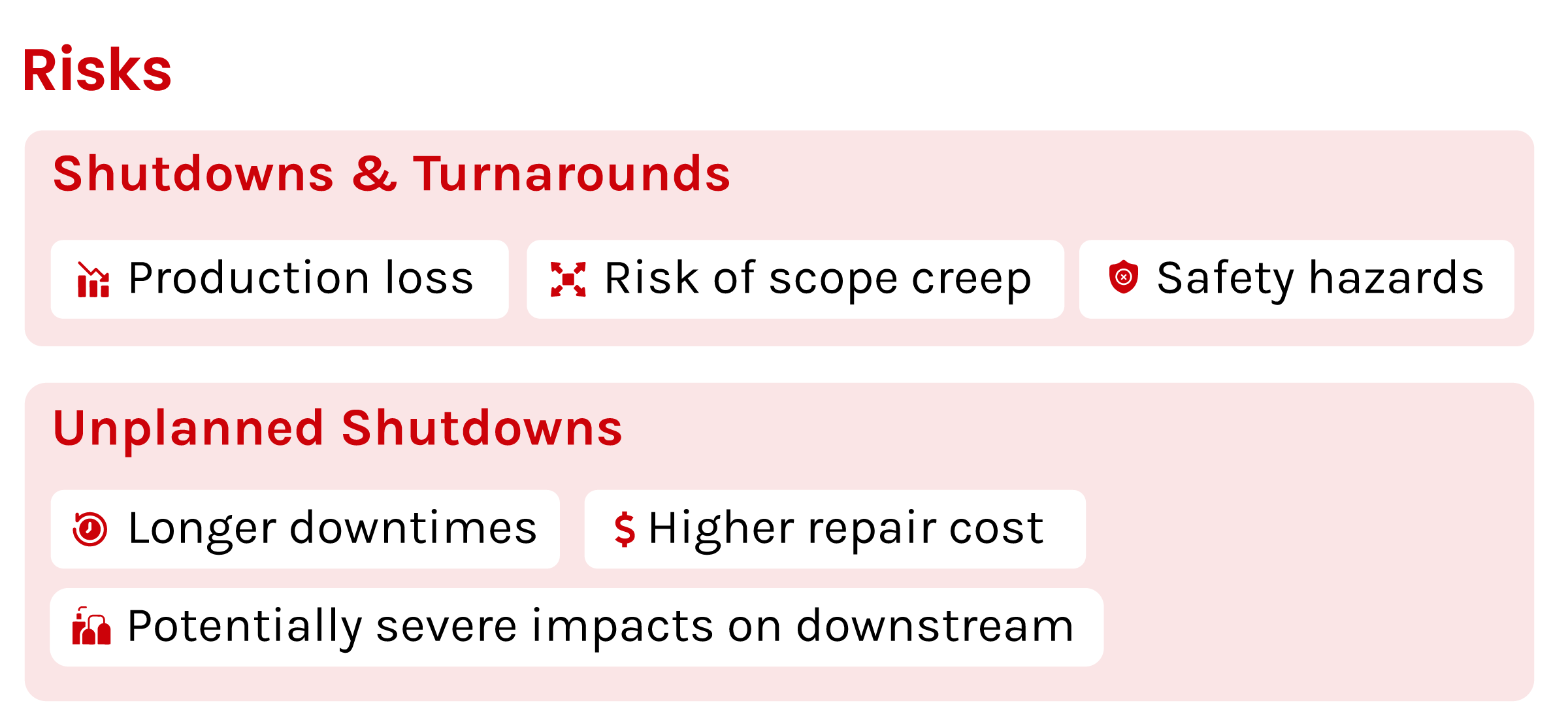

Risks, Countereffects, and Challenges

Despite careful planning, shutdowns and turnarounds come with inherent risks. The most immediate is production loss—even in the best-case scenario, output is paused, and revenue is impacted. There’s also the risk of scope creep, where additional issues discovered during execution lead to delays and budget overruns. Managing a large, temporary workforce can introduce safety hazards, and coordination failures can disrupt timelines.

In unplanned shutdowns, the counter-effects are more severe: longer downtimes, higher repair costs, and potentially severe impacts on downstream operations and supply chains.

For turnarounds, the scale of complexity is a challenge in itself—multiple contractors, capital project integration, aging infrastructure, and constrained schedules all increase the margin for error.

A Strategic Investment

Ultimately, shutdowns and turnarounds should not be seen as setbacks—they are investments. These carefully timed pauses allow companies to manage risk proactively, extend the life of their assets, and return to production stronger, safer, and more efficient. Success depends on preparation, coordination, and the ability to act on asset data with precision. When properly done, these moments of pause become the very foundation of a facility’s long-term resilience.