Hull damages such as cracks and discontinuities can lead to oil leaks, implicating direct emergency costs surpassing USD 50,000,000, according to Brazil’s National Petroleum Agency. From oil spills to accidents, the consequences of hull damage on oil and gas operations are far-reaching. Besides that, hulls are the exoskeleton of offshore units, requiring regular, accurate, and efficient maintenance procedures to address the excessive wear and tear, cracks, and anomalies that these structures are exposed to.

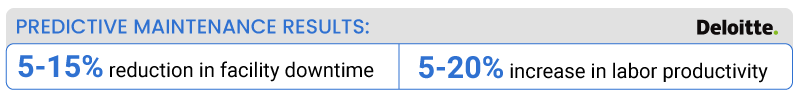

Ensuring adequate maintenance and repairs demands inspection procedures that often require rope access techniques. Even though it is a common practice, it exposes inspectors to complex activities in hazardous environments. In these conditions, understanding the importance of prevention and timely repairs is a crucial aspect of minimizing environmental effects and safety risks. Deloitte reported in 2022 that predictive maintenance can result in a 5-15% reduction in facility downtime and a 5-20% increase in labor productivity. Knowing that predictive maintenance is the key to guaranteeing accurate and effective structure treatment and maintenance schedules, what can industries do to build an effective hull damage prevention program?

1- Investing in Quality Coating Systems

Selecting high-quality materials and effective coating systems is pivotal in preventing hull damage. Investing in robust and corrosion-resistant materials during construction or repair can enhance the vessel’s longevity and reduce the likelihood of structural degradation. Similarly, using advanced coating systems designed to withstand harsh marine environments, such as anti-corrosion coatings, anti-fouling paints, and cathodic protection, are commonly employed practices to protect the hull against corrosion, biofouling, and other damaging processes.

In the same perspective, surface preparation processes are as important as coating the hull itself, Ultra-High Pressure Water Jetting is the primary method for achieving the desired surface profile, which is the microscopic roughness of the surface that optimizes coating adhesion.

2- Implementing Robust Maintenance and Inspection Protocols

Assertive inspections and maintenance are crucial for identifying and addressing potential hull damage before it scales. Ship and FPSO operators should establish comprehensive protocols that encompass thorough inspections of the whole hull structure, coating systems, and higher corrosion-prone areas. According to the article ‘’Condition-Based Monitoring and Maintenance: State of the Art Review’’, these protocols generate several advantages for industries, such as:

- Reducing downtime and maintenance expense by eliminating unnecessary maintenance;

- Providing an early failure detection mechanism to increase asset availability, avoiding unnecessary downtime;

- Supporting continuous improvement ensuring accurate and consistent response to developing conditions;

- Providing better decision-making for operations, engineering, and maintenance staff;

- Providing integration of control, safety, and maintenance environments.

Inspection campaigns are normally conducted by trained personnel or through the use of advanced technologies, such as Computer Vision and Reality Capture that reduce the need for operators exposed to hazards. Protocols are the foundation for mitigation actions in any quality control program, ensuring preparedness for promptly identifying and repairing any signs of damage, the risk of catastrophic failures and subsequent environmental damage can be significantly reduced.

3- Training Crew Members and Preparedness

Considering the high-complexity environments that crew members face while embarked, it is important to recognize the limitations of People on Board (POB). One of the reasons for these limitations is the remote location of industrial operations. This remoteness can pose challenges in terms of accessibility to external resources and emergency response, which increases the importance of proper training and preparedness for the crew members. Additionally, they may encounter hazardous conditions, such as extreme weather events and heavy seas, that beyond the possibility of generating hull damages, also are endangering factors for both the crew members and the surrounding marine environment.

To mitigate these risks, comprehensive training programs should empower crew members to take proactive measures according to a different range of possible scenarios during operation. These programs should focus not only on process safety and maintenance procedures but also on the specific risks associated with FPSOs. This includes training on early detection of threats from hull damage, understanding of the importance and best practices of inspection procedures, and effective response protocols in the event of an incident.

By fostering a culture of environmental stewardship, on-site workers can actively contribute to minimizing the consequences of damage that may occur. Equipping crew members with the necessary knowledge and skills enhances their ability to respond promptly and effectively to hull damage, making ships and FPSOs more resilient against such incidents. In this context, it’s important to continuously update and improve training programs to keep up with evolving safety standards and technological advancements.

4- Collaboration and Regulatory Compliance

Lastly, collaboration among stakeholders, including ship operators and owners, regulatory bodies, environmental organizations, and researchers is pivotal for preserving the health and well-being of the marine ecosystem without compromising safety standards and production goals. According to the article ‘’On Ship Structure Risk and Total Ownership Cost Management Assisted by Prognostic Hull Structure Monitoring’’, traditionally performing maintenance generates time-consuming processes that analyze anomalies while the hull’s degradation doesn’t stop. Indeed, energy companies with marine operations must have well-defined processes and regulatory compliance

For this purpose, industries should cooperate with classification societies, entities that assess, certify, and ensure that ships and offshore structures are safe to operate and compliant with established standards and regulations. According to the American Bureau of Shipping (ABS), companies must adhere to specified conditions, maintain safety policies, and employ full-time Qualified Inspectors (QIs) for visual examinations to safeguard the hull’s structural integrity. In these conditions, fostering information sharing and best practices through industry associations and platforms can enhance knowledge exchange and ensure continuous improvement in preventing and addressing hull damage.

5- AI Predictive Maintenance & Computer Vision

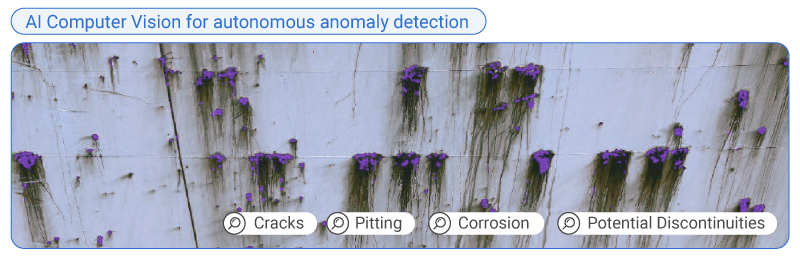

Given the hazardous conditions and high-complexity intervention programs related to hull integrity management, artificial intelligence (AI) offers a compelling counterpoint to traditional inspection methods by processing historical performance datasets of machines to forecast when one is likely to fail, limit the time it is out of service, and identify the root cause of the problem. Unlike traditional planners, this advanced analytics approach considers thousands of variables and constraints to support decision-making. Ship operations should embrace Artificial Intelligence to assess vessels’ structural integrity continuously.

This technology can analyze real-time data, monitor stress levels, and predict potential weak points, enabling proactive maintenance and addressing issues before they escalate. Additionally, Reality Capture techniques, such as drone images or photogrammetry, combined with AI Computer Vision to reduce operator exposure to hazards and foster a more accurate method of detecting hidden defects and areas susceptible to damage that could be difficult to locate or access. This method makes it possible for operators to improve and safeguard decision-making, comparing the real impact of different parameters on business outcomes before making decisions and, in many cases, to consider counterintuitive actions that might improve productivity or profitability.

Conclusion

Furthermore, building an effective hull damage prevention program is essential for safeguarding marine ecosystems, optimizing operational efficiency, and ensuring worker safety. The aforementioned measures not only support a more adequate, reliable, and faster structural integrity management of ships and offshore operations but also contribute to a more sustainable and resilient maritime industry. Adopting these strategies ensures proactive management and continuous improvement. Meanwhile, each proactive measure aiming to optimize the safety and integrity of the process guarantees a more efficient and reliable operation.