The search for digital solutions to the challenges faced in the oil and gas industries intensifies every year. According to BDO Global, it is predicted that the digital oilfield market, consisting of the internet of things, analytics, and cloud computing, will surpass US$20 billion by 2023.

In this dynamic scenario, it becomes increasingly evident that the Oil and Gas sector is embarking on an ambitious journey towards the integration of digital technology as indispensable tools to tackle their most pressing challenges. Among the myriad of trends shaping the landscape, certain key areas emerge as paramount in the oil and gas industries, with a specific focus on optimizing maintenance processes and facilitating a smooth transition towards net-zero. Now, let’s delve into the top three trends that are set to dominate the oil and gas industries in 2024:

1. Critical Equipments Analytics

The challenges associated with industrial maintenance highlight a crucial issue: the limited digitization of processes and lack of contextualization of data. These factors are concerning the efficiency and safety of critical equipment, resulting in losses of accurate asset failure prediction.

Fortunately, the continuous advancements of digital systems that leverage the Internet of Things (IoT) and data collected by field sensors have revolutionized the analysis of industrial efficiency and safety. However, despite these advancements, integrating disparate sources of information and achieving meaningful contextualization of generated data to enhance managerial decision-making has remained a challenge.

To address this, the adoption of cutting-edge technologies aims to deepen the digital transformation process and enhance database integration, such as Enterprise Resource Planning (ERP) and Plant Information Management Systems (PIMS). By centralizing the vast amount of data collected in a single repository, these technologies enable:

Enhanced operational safety:

By proactively identifying potential equipment failures and preventing accidents through advanced analytics, the overall safety of operations can be significantly increased.

Reduction in unplanned downtime:

More trusty data analysis, enabled by these technologies, leads to a decrease in unplanned downtime. By identifying patterns and anomalies, maintenance teams can intervene before failures occur, thereby increasing the mean time between failures and optimizing operational uptime.

Improved maintenance planning:

By leveraging consolidated and organized data, industry maintenance planning becomes more precise and effective. This results in reduced Operational Expenditure (OPEX) required to address unplanned failures, as maintenance activities can be scheduled proactively, minimizing disruption and maximizing efficiency.

As we look ahead to 2023, it is evident that investing in technologies enabling predictive failure analysis of critical equipment based on historical data and facilitating continuous monitoring of equipment efficiency becomes a top priority. Such investments pave the way for enhanced productivity, cost reduction, and accident prevention, ultimately driving toward a safer and more efficient industrial landscape.

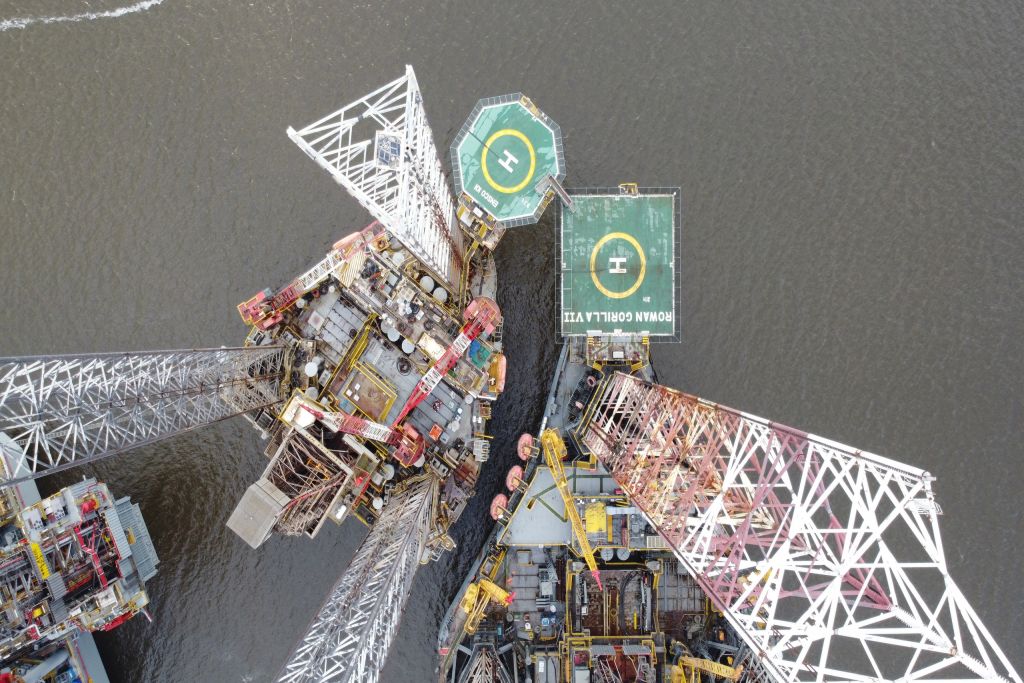

2. Digital fabric maintenance

The optimization of fabric maintenance stands out as a pivotal focus that demands increased attention from industries within the sector. Presently, this process unfolds in a predominantly analog manner, necessitating many field workers to conduct inspections and assess the integrity of structures, piping, and equipment. Consequently, a deluge of reports is generated and scattered across various information management systems employed by companies, impeding fast and accurate risk analysis and maintenance planning.

Hence, there arises a pressing need to digitize this process and unlock efficiency gains while reducing costs. Encouragingly, certain companies are already spearheading the development of technologies that leverage Artificial Intelligence (AI) to detect anomalies in industrial plants. However, this example merely scratches the surface of the potential applications.

Throughout 2024, the implementation of such technologies in the Oil and Gas industries will become increasingly prevalent, particularly as a means to mitigate corrosion-related issues. By embracing AI-driven solutions, companies can streamline fabric maintenance, optimize time utilization, and minimize expenses. Remote inspection capabilities enabled by these technologies empower teams to swiftly identify and address potential concerns without the need for extensive on-site presence.

The transformative power of these advancements extends beyond remote inspections. By integrating AI and digitalization, data from multiple sources can be consolidated, enabling advanced analytics and predictive maintenance models. This shift not only enhances the accuracy and efficiency of maintenance planning but also fosters proactive decision-making, reducing downtime and maximizing asset performance.

In summary, the year 2024 will witness the accelerated adoption of AI-driven technologies within the oil and gas industries, revolutionizing fabric maintenance practices. This digital transformation holds immense potential to optimize resources, cut costs, and tackle corrosion challenges, ultimately driving operational excellence and bolstering the industry’s competitiveness.

If you want to learn more about Digital Fabric Maintenance, fill out the form

3. Optimal Asset Integrity Management

The Oil and Gas industries currently face significant pressure for energy transition, as the global focus shifts towards reducing carbon emissions and embracing sustainable practices. This transition poses both challenges and opportunities for these industries. However, one crucial aspect that can drive positive change is developing an optimized Asset Integrity Management (AIM) framework.

Implementing a robust AIM process becomes a vital component in lowering carbon emissions and improving operational efficiency within these industries. By ensuring that assets operate at their optimal capacity, energy consumption can be enhanced, and energy resources can be better managed. This can directly contribute to the reduction of carbon emissions associated with a plant’s operation.

Furthermore, Asset Integrity Management serves as a significant step in preventing accidents and asset failures. By prioritizing the integrity of critical infrastructure, industries can proactively identify and address potential risks, thus mitigating the likelihood of environmental damage. Through rigorous inspection, maintenance, and monitoring practices, AIM fosters a safer operational environment, ensuring the protection of ecosystems and minimizing the negative impact on surrounding communities.

In addition to environmental considerations, an optimized Integrity process comes as an active contributor to the broader spectrum of Environmental, Social, and Governance (ESG) factors. By preventing incidents and minimizing environmental damage, industries demonstrate their commitment to responsible and sustainable operations. This, in turn, can be perceived as a legit corporate good reputation, strengthening stakeholder confidence, and fostering a positive social impact within the communities they operate.

Conclusion

In essence, the strategic embrace of technology represents a pivotal step for the Oil and Gas industries to remain current and gain a competitive edge. By harnessing the power of Digital Transformation to the operate and maintain phase, these companies can unlock an incredible potential that ranges from cost reduction through optimized maintenance practices to facilitating seamless energy resources management. Undoubtedly, the primary growth drivers for these industries in 2024 will revolve around the adoption and effective utilization of applied technologies.

If you want to learn more about some results achieved using these technologies and approaches, Fill out the form below!