Understanding Dropped Object Prevention for Energy Industries

In 2016, dropped objects from Offshore Oil facilities resulted in 255 worker fatalities in the United States, according to the Bureau of Labor Statistics, an alarming statistic that made clear the urgency of a curious, but important safety protocol that industries needed to adopt: fighting gravity. However, these incidents are far from inevitable and can be significantly reduced through a robust Dropped Object Prevention program. And, considering the scale and complexity of the energy industry’s operations, these programs became a fundamental piece of Industrial Safety and Risk Management. But what defines a Dropped Object? What is a Dropped Object? [...]

5 Essentials of Hull Damage Prevention for ships and FPSOs

Hull damages such as cracks and discontinuities can lead to oil leaks, implicating direct emergency costs surpassing USD 50,000,000, according to Brazil's National Petroleum Agency. From oil spills to accidents, the consequences of hull damage on oil and gas operations are far-reaching. Besides that, hulls are the exoskeleton of offshore units, requiring regular, accurate, and efficient maintenance procedures to address the excessive wear and tear, cracks, and anomalies that these structures are exposed to. Ensuring adequate maintenance and repairs demands inspection procedures that often require rope access techniques. Even though it is a common practice, it exposes inspectors to complex [...]

The Future Lies in the Past: Embracing Mature Fields for Tomorrow’s Energy

A 2011 study by IHS Cambridge Energy Research Associates reported that approximately two-thirds of global daily average oil production comes from mature fields and that the percentage is increasing over time. Indeed, it’s evident that mature fields have become a fundamental piece of the petroleum exploration sector, but what exactly are mature fields? According to Parshall (2012), mature fields are defined by years of production and aging infrastructure. For a field to be considered mature, it had to produce more than 50% of its established proved plus probable resource estimates or have produced for more than 25 years. In this [...]

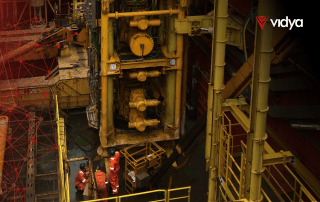

Exploring the Depths: Understanding Offshore Oil Drilling

Until 1894, we didn’t know extracting crude oil from subsea environments was possible. This changed when the lure of offshore production enticed Henry L. Williams and his associates to build a pier 90 meters out into the Pacific — and assemble a standard cable-tool rig on it. Since then, oil extraction has evolved in unprecedented ways. In recent years, new technologies have emerged as powerful tools for addressing the inherent challenges of exploring previously unreachable resources. Indeed, subsea drilling still represents a complex operation that requires advanced techniques and skilled teams to achieve optimal efficiency and safety. And, despite the [...]

Vidya showcases AI Innovations for Offshore Energy at OTC 2024

Vidya Technology is attending the Offshore Technology Conference 2024 in Houston, TX. You can find Vidya at the halls of this year’s OTC in Brazil Pavillion at booth 624. The conference will take place between May 6-9 at the NGR Park in Houston, Texas. Beyond that, the event will reunite global industry leaders to share ideas and innovations and discuss the offshore energy sector's most pressing challenges. OTC 2024 will connect 31,000+ offshore energy professionals from more than 100 countries to collaborate and discuss the latest developments needed to accelerate the global energy mix. Whether it's oil and gas, solar, [...]

Why Reality Capture is a must to report anomalies in industrial inspections

Industrial inspections consist of reporting anomalies to later perform maintenance plans. For this purpose, companies display several methods to inspect assets that can be divided into two major categories: the traditional methods and the digitized ones. In this context, these two groups present clear disparities in the benefits they generate to operators. While traditional methods still expose professionals to risky and time-consuming activities, new digitized ways of capturing reality have intuitively fostered safety and uptime for industrial inspections. Indeed, the new optimized methods of visually inspecting assets have accurately illustrated industrial realities to streamline maintenance actions. Thus, reporting anomalies with [...]

AI-driven Hull Inspections: Streamlining Safety and Efficiency

Vessels are crucial parts of different industrial operations. Considering this, the ship's main body: the hull, must be regularly inspected to ensure high asset integrity, safety, and efficiency standards. Hull damages such as cracks can lead to oil leaks, which can implicate direct emergency costs that surpass USD 50,000,000 according to Brazil's National Petroleum Agency, which is 100x more expensive than the investment to repair the defects on time (before the accident) not including compensations, fines, and asset depreciation. In this regard, hull inspections are a maintenance procedure that helps energy companies and bulk cargo transporters maintain high safety, compliance, [...]

What is the difference between AIM and APM?

Asset Integrity Management (AIM) and Asset Performance Management (APM) are concepts that often get confused. Indeed, both focus on enhancing maintenance plans while reducing costs. However, it is necessary to understand which problems they specifically address to visualize the scope of their benefits. In this context, let’s learn about the main differences between these two vital concepts for heavy asset industries. The role of AIM As the name suggests, Asset Integrity Management focuses on the physical integrity of the asset, its purpose is to improve operational safety and maintenance planning. This strategy provides necessary outputs to industries about [...]

Why predictive maintenance isn’t always an answer

Intro Predictive maintenance has proven to be an effective methodology for enhancing the lifespan of valuable assets in the industrial sector, as it allows companies to predict when equipment is likely to fail or stop. This way, proactive measures can be taken to prevent downtime and reduce maintenance costs. Besides that, a November 2021 report from IoT Analytics estimated that the $6.9 billion predictive maintenance market would reach $28.2 billion by 2026. This showcases the immense potential this technology has, allowing companies to optimize their outcomes while reducing downtime. However, if this technology isn’t adequately implemented, [...]

Unlocking AI’s accuracy and reliability

AI's growth scenario From its early days as a theoretical concept to today's omnipresent reality, AI's journey has been characterized by exponential growth. According to a 2022 IBM research, more than a third of companies (35%) report the use of AI in their business, a four-point increase from 2021. This illustrates a key change in the way we face reality, but different from other technological revolutions: today’s tool learns from its own experience at increasingly higher speed and scale. These tools are programmed to have a human-like thought process. Moreover, they are now a reality in the [...]