This year, at the Offshore Technology Conference (OTC) in Houston, a new benchmark was set for offshore asset maintenance and corrosion control. Vidya, in collaboration with BRAVA Energia, presented a technical paper exploring a game-changing approach to the industry’s enduring challenge: reducing the risk of corrosion while optimizing operational efficiency in brownfields.

Titled “Digitalization of the Corrosion Identification Process Using Digital Technologies in Mature Fields”, the paper was co-authored by teams from Vidya and BRAVA Energia, including: Lincon D’Aquila, Integrity and Maintenance Manager at Brava, Otavio Correa, Vidya’s CEO, Jorge Mariano, Vidya’s VP US, and André Andrade, Marketing and Innovation Analyst. It introduces a replicable methodology for improving Corrosion and Fabric Maintenance in offshore assets through artificial intelligence, spatial computing, digital twins, and strategic alignment with operational realities.

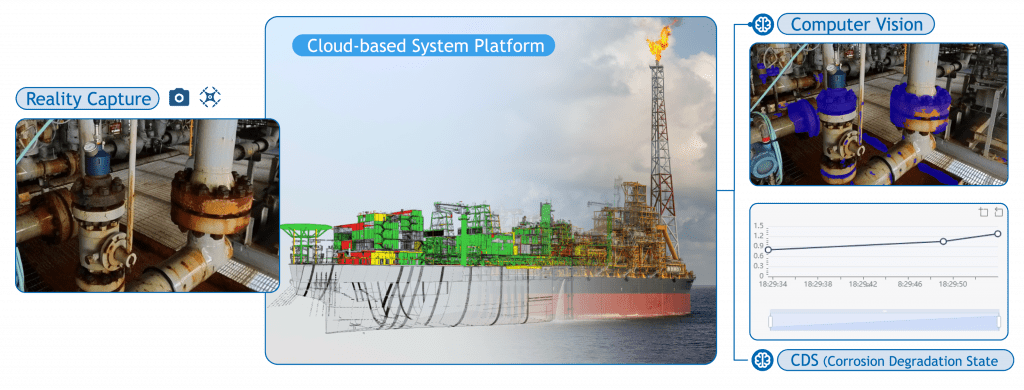

The proposed framework was successfully implemented in a FPSO unit in Brazil, enabling better resource planning, streamlined inspection routines, and a proactive integrity management process, all within a single digital platform.

Challenges Offshore, Solutions Onshore

Corrosion and Fabric Maintenance are among the most resource-intensive and operationally complex activities in the offshore energy industry. Historically, data fragmentation, lack of digital integration, and disconnection between planning and execution have hindered performance. Vidya and BRAVA Energia joined forces to address these persistent challenges through a unified methodology—aligning technical planning with operational execution using digital tools.

The project showcased at OTC bridges this gap by integrating data from multiple data sources (including Engineering documents and reports, P&IDs, and others) into one centralized environment. The result was a significant increase in productivity, a reduction in the number of people on board, and a stronger connection between onshore planning and offshore execution.

From Paper to Practice

The following sections outline the key phases of the project developed by Vidya and BRAVA Energia, showcasing how a structured application of technology was essential in transforming traditional offshore maintenance and integrity practices. This summary highlights the journey from initial planning to an integrated digital execution, demonstrating how data, artificial intelligence, and predictive models were applied to enhance operational efficiency and ensure greater safety in offshore operations.

Phase 1: Data Consolidation and Integrity Modeling

With the scope and standards set, the teams moved to create a centralized model of the asset. This involved:

- Consolidating historical and engineering data;

- Mapping and contextualizing components on the digital model.

Through the Vidya Platform, disparate datasets were unified into a single environment. This model became the core of a digital twin structure, enabling visualization and analysis across the asset’s landscape.

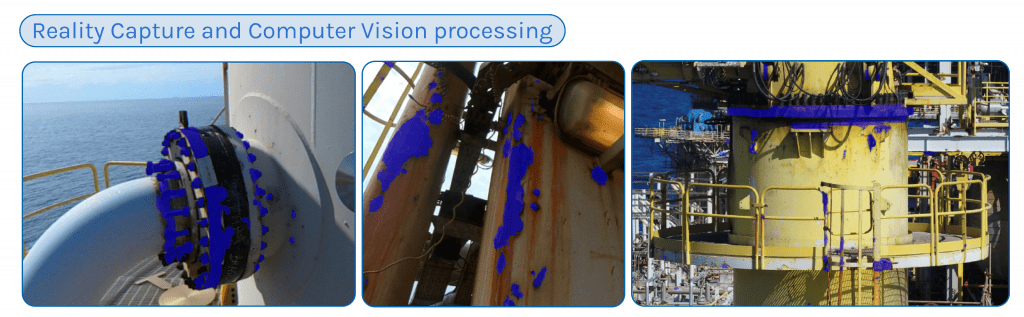

Phase 2: Reality Capture and Computer Vision processing

In this phase, the project transitioned to operational execution, deploying digital workflows powered by high-fidelity data capture, artificial intelligence, and predictive analytics.

A key enabler was the Reality Capture process, which addressed offshore inspection challenges by using drone-based imaging to safely and efficiently collect high-resolution visual data. This approach significantly reduced personnel exposure in hazardous zones and ensured detailed photographic coverage of difficult-to-access structures such as cranes and flare stacks. The captured images were then integrated into the platform’s 3D model, enhancing the fidelity of the Digital Twin with the current visual context.

Following image acquisition, the system applied Machine Vision techniques to process and analyze the captured visuals. This AI model automatically detected and classified signs of corrosion, cracks, dirt accumulation, and other surface anomalies. The results were spatially mapped within the digital twin, enabling inspectors to identify and prioritize risk areas visually and interactively.

To quantify the severity and predict the evolution of these anomalies throughout time, the system incorporated the Corrosion Degradation State (CDS) model. This framework evaluates corrosion using standardized criteria, such as damage extent, surface condition, and degradation patterns, and forecasts its progression using a hybrid linear-logarithmic growth model, calibrated with real-world data.

Together, these technologies allowed BRAVA Energia teams to:

- Deliver accurate square footage affected by corrosion in ft²/m² and area that needs painting;

- Generate maintenance plans based on AI-detected conditions and risk models;

- Enhanced allocation of inspection and repair tasks and efforts by criticality and corrosion severity;

- Risk models for prioritizing efforts on corrosion findings;

- Contextualized Integrity data on the Digital Twin;

- Fast and easy access to field images from Reality Capture.

This digitally integrated approach significantly enhanced inspection reliability, safety, and efficiency—marking a key transformation in the asset integrity workflow.

Results: From Complexity to Clarity

By applying the full implementation process, the system successfully covered all areas of the topside and main deck. Specific areas such as the flare stack, cranes, lifeboats, living quarters, offloading structure, and helideck were also included. The Reality Capture phase during a ten-day offshore campaign involved just one professional onboard.

Following image acquisition, the AI-driven post-processing phase was completed in 35 days. This digital approach reduced the overall inspection timeline from 170 days to just 45 days, a 73% reduction in time compared to traditional methods.

A Model for the Future

The methodology developed through this project is replicable and scalable. It presents a new standard for offshore units, especially as the energy industry accelerates its transition toward digital operations.

For Vidya and BRAVA Energia, this collaboration at OTC Houston wasn’t just a showcase of a successful project. It was an invitation to the industry: to rethink, retool, and redefine how we manage the integrity of our most critical assets.

Beyond theoretical models, the presented case demonstrates the practicality and impact of a fully digital, integrity-focused solution. By leveraging the Vidya System Platform, BRAVA Energia took a forward-looking step into the future of offshore operations where informed decisions are made faster, budgets are better managed, and asset longevity is no longer left to chance.

We extend our sincere thanks to BRAVA Energia for its trust, collaboration, and vision throughout this partnership. Together, we’re setting a new benchmark for what’s possible in the digital transformation of the energy sector.