Classified by the Bureau of Labor Statistics as one of the riskiest industries, oil and gas operations face numerous challenges, including equipment failures, accidents, and safety hazards. Certainly, this sector is subjected to safety threats due to the complex processes and hazardous environments in which it operates. For this reason, high-complexity facilities such as oil and gas need to target safety and risk assessments as fundamental pieces of operational management.

In this context, Vidya presented two technical articles regarding our deeptech solutions at ROGe 2024. The first presentation, which took place on September 23rd, discusses the Digital Process Safety application. The article showcases the application’s tracked and proven impact in optimizing the risk management of an operational unit by controlling, visualizing, and planning mitigating actions.

The article was further recognized at ROGe 2024 as the best paper in Innovation and Digital Transformation in the Plínio Cantanhede Award. Organized by the Brazilian Petroleum Institute (IBP), this award honors the best technical papers approved at ROGe Expo and Conference events, highlighting the impact of innovative solutions in addressing the sector’s critical challenges, such as those presented by Vidya’s Digital Process Safety application. Get to know our article better in this blogpost:

”Process Safety Management in Oil and Gas Operating Units Through Digital Twin Platform: A Digital Approach for Safety Control and Process Intervention”

The oil and gas industry operates in intricate, high-risk environments where operational safety is of central importance. Within these units, production efficiency directly correlates with maintenance efficacy. Ideally, maintenance strategies should be meticulously planned and aligned with an organization’s overarching goals and stakeholder expectations. This plan should encompass crucial factors like maintenance goals, resource availability, and technical capabilities.

Indeed, effective maintenance strategies should anticipate potential issues, meticulously craft schedules, manage external contractors, maintain financial control, ensure logistical efficiency, and foster adaptability during maintenance execution. Regarding this, comprehending optimal timing and location for maintenance interventions becomes increasingly complex without the support of a robust data infrastructure for informed decision-making.

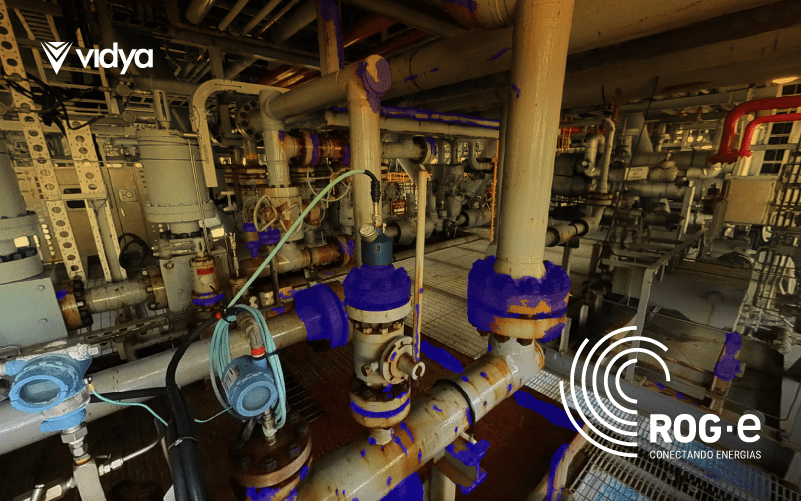

The project aimed to develop an application to optimize the risk management of an operational unit by controlling, visualizing, and planning mitigating actions. Thus, the solution developed by Vidya consists of a digital integrity platform that contextualizes risk assessment documents such as HAZID and HAZOP, shutdown and turn around data, inspection reports, and integrity documents in a 3D environment with all the sequence of actions, anomalies, failures, and scenarios listed and visually animated, enabling operators to plan shutdowns, maintenance campaigns, and interact with plant information via cloud web, tablets, and mobile applications.

Vidya’s participation at ROGe 2024