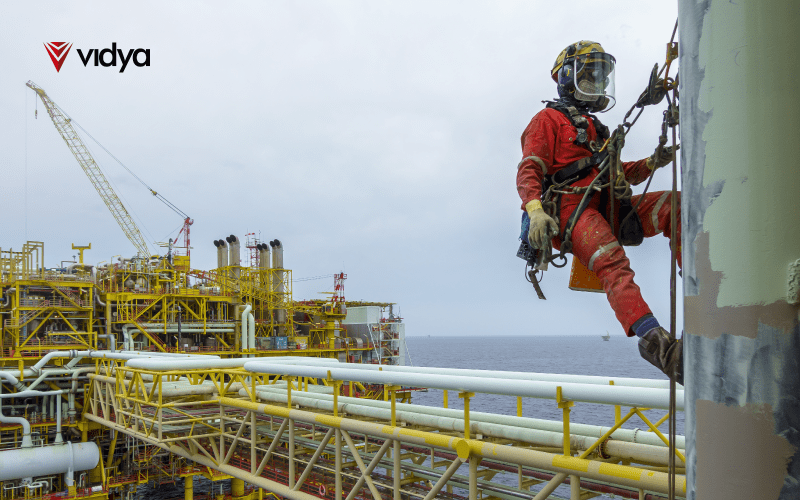

Offshore industrial operations are risky environments for on-site workers. This group of people, referred to as People on Board (POB), is responsible for inspecting, executing maintenance, and ensuring operational safety in the facility. However, oil and gas facilities may present risks that result in incidents such as explosions, dropped objects, oil leaks, and others. Besides that, unplanned events happen, requiring workers to have an immediate response to mitigate the occurrence.

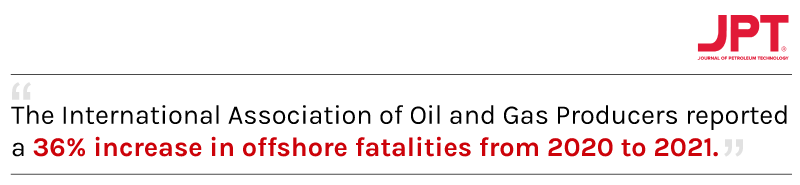

The International Association of Oil and Gas Producers reported a 36% increase in offshore fatalities from 2020 to 2021.

In this context, oil industries have to deal with limitations on the number of POB allowed in the facility. Thus, the distribution of on-site interventions needs to be tracked and managed to ensure safety and resource allocation while adhering to regulatory compliance. However, despite reducing the POB count may appear straightforward, it becomes imperative to have people on board to address integrity issues with preparedness. So, how can POB management be such a challenge for industries?

Why POB Management can be a hurdle

The article ‘’Maritime Platform Facilities POB Plan Management Module Research and Development’’ stated that when dangerous situations occur in offshore platforms, such as typhoons, distress, facility pipeline breakage, etc., it can lead to huge property losses and threaten the safety of offshore operators. In this manner, operating in naturally hazardous and distant environments with significant amounts of flammable hydrocarbons requires careful management of People on Board. Besides meticulous planning of interventions, the activities performed by on-site workers are characterized by complex integrity problem-solving with no room for error. Still, what factors do operations need to keep in mind to make the most out of their POB?

1- People on Board represent a valuable resource for the asset activities

Restrictions on POB numbers refer to the most valuable resource oil and gas companies have, their human expertise. In this regard, the article ‘’Maintenance Problem Identification on Offshore Platforms Through Analysis of Maintainer Work’’ highlights that most on-site workers present different mitigation strategies for all sorts of maintenance events, generating different yet valuable perspectives on Asset Integrity Management. Furthermore, the diverse expertise and hands-on experience of the POB contribute to building a solid maintenance program dawn on the different viewpoints and solutions proposed.

2- Problems faced by the People on Board

Professionals face many challenges related to safety, logistics, technology, and human factors when displaced to offshore operations. These encompass the asset’s remote location, difficult-to-access areas, dangerous activities, unstable weather, and isolation from their families for extended periods. And, when it comes not to just one professional, but an entire group, the operation carries many risks to the people involved, which may implicate direct expenses and indirect repercussions, amplifying the economic burden.

As a result of this dicey scenario, there are several concerns about POB limitations in offshore facilities, such as planning, conducting, and providing direction for on-site activities effectively and efficiently. For this purpose, new technologies have allowed operations to reduce staff and increase efficiency, executing the job faster through the synergy between experienced workers and technology.

How technology reduces the POB numbers

POB numbers indicate how many professionals will be allocated for on-site activities, such as inspections, repairs, and paintings, among other on-board tasks. For this purpose, It is no longer necessary to have entire teams in the facility to perform interventions. Industry leaders have been reducing POB numbers by automating processes with the support of cutting-edge technologies. According to Statista, the size of the global industrial automation market should reach roughly 265 billion U.S. dollars by 2030.

In this sense, companies can achieve enhanced processes and a more accurate operational panorama by harnessing digital innovations that have been optimizing inspection, maintenance, and safety control procedures. But how exactly are these activities being optimized?

Inspections

Industrial inspections consist of reporting anomalies to later perform maintenance plans, often being a time-consuming and complex process. Indeed, while assets require inspections, operations must deal with limited time, budget constraints, and costly downtime. However, in this new scenario, it no longer takes months to complete inspections. Reality Capture methods such as robots, ROVs, and drones offer a welcome alternative to manual inspection methods by letting professionals digitally capture, share, and analyze real-world environment conditions to move faster and make more accurate maintenance decisions.

Maintenance

To address the costly, risky, and time-consuming processes of industrial maintenance, Artificial Intelligence has proven to be a helpful tool for reducing POB numbers with Predictive Maintenance. AI Predictive maintenance analyzes the historical performance data of machines to forecast when one is likely to fail, limit the time it is out of service, and identify the root cause of the problem. Thus, repairs, paintings, fixes, and other interventions can be easily managed by monitoring asset historical performance data, optimizing structure treatment and maintenance schedules. The result is a system that identifies small problems before they become big failures with interventions performed only when necessary.

Safety Management

Dealing with hazardous materials, demanding environments, and intricate processes and technologies reflects inherent POB limitations. For this purpose, industries adopt risk assessments to make crew members aware of the facility’s existing risks and safety procedures. Still, each piece of equipment has its risks in +200,000m² facilities full of other machinery. Furthermore, deeptech platforms have been supporting operations by contextualizing and crossing all engineering documents, risk assessment, shutdown, and turnaround data in a unique channel. In these conditions, operators can achieve a holistic point-of-view in risk assessment and emergency preparedness.

Conclusion

Managing People on Board (POB) in offshore industrial operations presents significant challenges due to the inherent risks and limitations of working in hazardous environments. The increasing complexity of maintaining asset integrity, coupled with the need for efficient resource allocation and safety management, underscores the importance of innovative solutions. Indeed, these technologies streamline processes and contribute to building a safer and more cost-effective operational framework. As the industry continues to evolve, leveraging digital innovations will be crucial in overcoming the hurdles associated with POB management and driving forward to a more responsible future.