Vessels are crucial parts of different industrial operations. Considering this, the ship’s main body: the hull, must be regularly inspected to ensure high asset integrity, safety, and efficiency standards. Hull damages such as cracks can lead to oil leaks, which can implicate direct emergency costs that surpass USD 50,000,000 according to Brazil’s National Petroleum Agency, which is 100x more expensive than the investment to repair the defects on time (before the accident) not including compensations, fines, and asset depreciation. In this regard, hull inspections are a maintenance procedure that helps energy companies and bulk cargo transporters maintain high safety, compliance, and efficiency standards.

However, inspecting offshore units’ exoskeletons isn’t such a simple task. Indeed, these structures are exposed to mechanical stress, impacts, and fatigue, which increase their susceptibility to corrosion, heightening their vulnerability to deterioration over time. In addition, traditional inspections involve the manual analysis and interpretation of extensive technical reports and require rope access techniques to inspect the structure. Knowing this, how can the integrity of hulls and tanks be managed efficiently? To answer this question, it is necessary to comprehend the process challenges.

Challenges of inspecting hulls

Hull inspections are crucial to the continuous operation of industrial vessels, ensuring the structure’s adequate integrity condition, elevated life cycle, and operational efficiency. In this context, hulls are designed and constructed according to relevant standards, regularly monitored for damages, defects, and anomalies, and maintained and repaired as necessary during operation. Additionally, coatings and antifouling systems are important measures for increasing resistance, fuel consumption, and environmental impact.

As part of the hull inspection process, several obstacles must be considered. For instance, worn-out surfaces commonly obstruct viewing, locating, mapping, and quantifying anomalies, critical areas, and repairs to fulfill structural protection. As a result, traditional manual reports do not achieve ideal Hull Integrity, representing a risky and time-consuming procedure. Factors such as working hung on ropes, unpredictable sea conditions, and potential equipment malfunctions contribute to the risks

In this circumstance, exposing inspectors to hazardous environments with mandatory rope access techniques requires a precise Hull Management strategy. Inefficient strategies may lead to structural problems such as leaks, accidents, and shutdowns, compromising HSE (Health, Safety, and Environmental) standards. According to Maritime Impact, 48% of total casualties were due to hull and machinery (H&M) damage.

Hull inspections also require rope use to another important area, the tank. The tank of an offshore unit serves as a critical component for the safe and efficient transportation of liquid cargo, such as oil and chemicals. These structures can be a headache to inspect due to the area’s poor lighting and the necessity of cleaning the tank to conduct inspections. Not being enough, performing tank inspections goes beyond anomaly detection, involving analysis of the project’s life cycle, finite elements, and structural engineering.

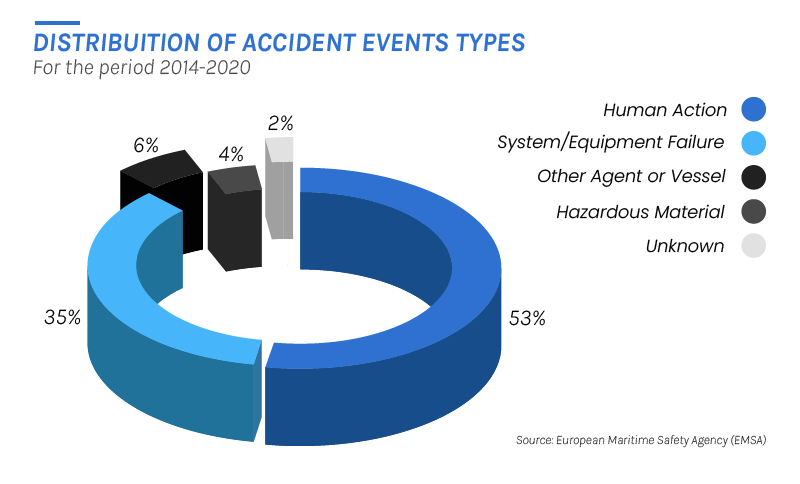

Besides that, the European Maritime Safety Agency (EMSA) reported that 53% of maritime accidents were caused by human action, and 35% by system and equipment failure. This can be due to decentralized, conflicting, and outdated systems. Meanwhile, digital-enhanced hull inspections are gaining ground. For this article, it’s necessary to understand how their demand arose.

How hull inspections are traditionally performed

Traditional hull inspection involves reporting visually identified anomalies in areas of over 16000m² where operators need to climb to access the external hull and the tank, not considering the other stages of hull management, such as planning, decision-making, and painting, which would still take several months to complete. External environmental factors, such as adverse weather conditions, can complicate the process. Storms, high waves, or strong winds can create unsafe working conditions for climbers. That being said, it’s clear that inspecting hulls is a risky and time-consuming process.

Beyond that, industrial operations generate gigantic amounts of data often unstructured, and hull management requires relating data from different hull parts. In this sense, non-ideal methods still rely exclusively on a series of robust documents for inspections. Consequently, maintenance teams must analyze many reports and documents to understand anomalies, priorities, and their correlation.

However, the criteria for approval to operate are extensive, complex, and bureaucratic. According to the American Bureau of Shipping (ABS), companies must adhere to specified conditions, maintain safety policies, and employ full-time Qualified Inspectors (QIs) for visual examinations to safeguard the hull’s structural integrity. Still, AI-driven solutions are rapidly becoming important assets to address fatigue, stress, fracturing, and poor-integrity conditions operators may encounter while operating and complying with regulating organizations.

Using AI to support Hull Inspections

To solve these challenges, Vidya Technology – an international Deeptech specialized in AI software with hardware and engineering experience – developed a digital platform solution to the specific challenges regarding the Hull and Tank Integrity of Oil and Gas (such as FPSOs, FSOs, and WHP), and Mining vessels. Vidya’s approach guarantees AI-driven precise hull structural integrity by contextualizing historical integrity data on measurement points, delivering the necessary results for the engineering analysis, inspection plans, and support for both inspection and maintenance actions and class society evaluation.

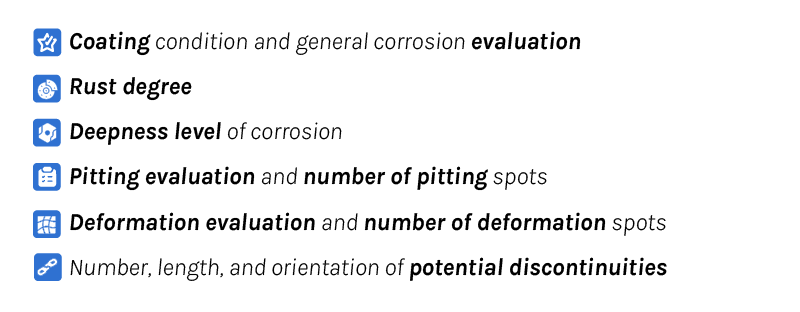

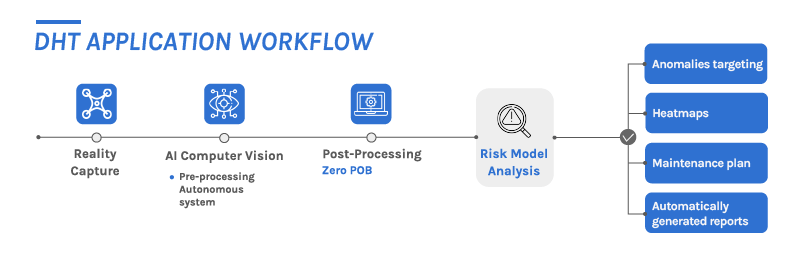

The solution incorporated reality capture to collect images of hull structures, which later were processed by the AI Computer Vision, a proprietary model specifically developed and trained by Vidya for the challenges of Industrial Hull Integrity. This algorithm autonomously identifies anomalies such as pitting, welding, potential discontinuities, and corrosion using Deep Neural Networks. In this context, the AI evaluates visual anomalies in each hull component based on the company’s business rules, such as:

Vidya’s Hull Integrity solution encompasses both external and internal areas of a Hull. The Digital Hull Tracking (DHT) application was designed for the external hulls while the Digital Naval Tracking (DNT) application was for the vessel’s tank. Indeed, autonomous anomaly identification is particularly advantageous in process industries such as Oil and Gas and Mining, where extracting natural resources implicates high levels of wear and tear on equipment, corrosion, and very high risks in the event of accidents or failures.

Oil and Gas Application

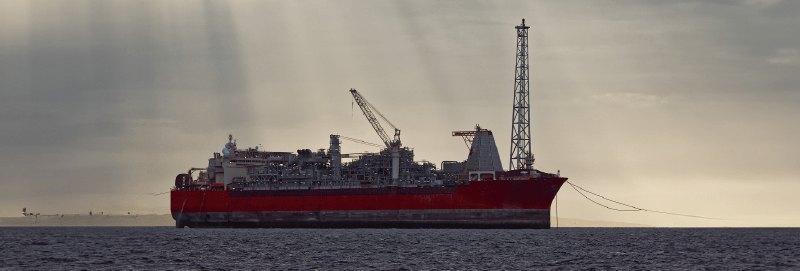

In the oil and gas industry, diverse offshore units serve essential functions in different phases of the production chain. Tankers are pivotal for transporting large volumes of crude oil and refined products globally, with classifications like Very Large Crude Carriers (VLCCs) based on size. Floating Production, Storage, and Offloading (FPSO) vessels play a crucial role in offshore exploration and production, extracting and processing hydrocarbons directly from the seabed while also storing oil before transfer to other means of transportation

The hull of a vessel is constantly exposed to harsh marine environments, including saltwater, which accelerates the corrosion process, threatening the ship’s integrity despite performing regular maintenance. Yet, using AI to manage this process is reshaping Hull Integrity. However, this technology is not replacing human workers, but synergizing human-AI collaboration through data-driven insights. The algorithm developed by Vidya, AI Computer Vision, achieves 90% precision on visual anomaly identification, generating traceable reports that allow faster and safer maintenance plans.

Mining Application

In the Mining industry, bulk carriers are crucial for transporting vast quantities of raw materials, such as coal, iron ore, and other minerals, across global waterways. These vessels are specifically designed to handle and transport large bulk cargoes efficiently. These facilities are integral to the mining supply chain, providing a cost-effective and reliable means of moving substantial amounts of raw materials from mining sites to processing facilities and ultimately to markets worldwide

Vidya’s Hull Integrity solution plays a crucial role in enhancing bulk carrier integrity. Besides these facilities being inherently exposed to liquefaction, they face hull anomalies such as corrosion, pitting, welding, and other discontinuities. And, while transporting hundreds of tons of minerals, the overall integrity of the ship must be prioritized. In this regard, Vidya’s solutions monitor the structural degradation of the hull over time, optimizing control over repairs and maintenance planning.

How hull inspection challenges were solved

In recognition of the bureaucratic and risky challenges presented by hull inspections, industries can leverage the AI outputs, generating coating and maintenance plans, which include components, affected areas, areas to be painted, locations, and prioritizations. This way, maintenance plans, and regulation compliance are streamlined, facilitating the class society’s evaluation.

External hull: Digital Hull Tracking

The solution combines reality capture via drone images in a 3D environment with Artificial Intelligence to view, locate, classify, and quantify potential discontinuities, pitting, and critical corrosion points. As a result, the application provides a digital and visual management system for hull inspection, with anomalies mapped and classified with maintenance action support and generating integrity notations in less than 30 days.

Tank: Naval Digital Tracking

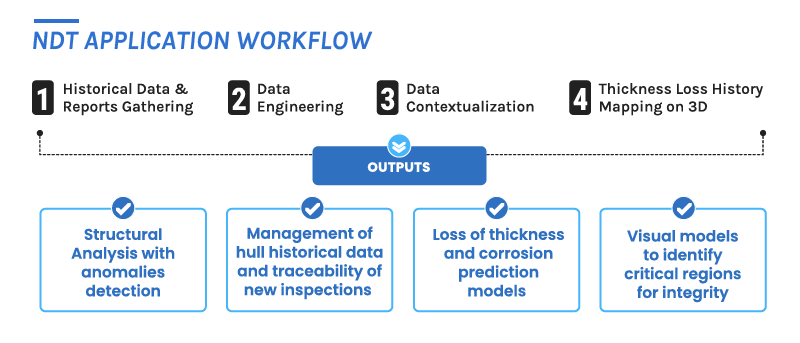

The application contextualizes historical integrity data (such as thickness measurement points, temporary repair history, and measurements in critical areas, among others) in a 3D environment. In this way, the solution enables the optimization and automation of integrity inspections and maintenance plans, supporting engineers in interacting with the Classification Society of the unit, and delivering it in 60 days or less.

Conclusion

Vidya’s applications target more than just mapping anomalies, the solution reduces risks in the inspection phase, enhances control over temporary repairs, and monitors the evolution of structural degradation over time. Our AI platform fosters a culture of continuous improvement, amplifying human wisdom with data-driven insight. Vidya’s solutions are designed to complement and empower, not replace, the incredible skills and knowledge of our users.