Corrosion. AI. Digital Twin. You already know that the Vidya System Platform (VSP) stands out in these disciplines. But what started as a corrosion-focused platform quickly became a versatile system for understanding and managing complex industrial realities. Its evolution reflects how technology and user demands continue to shape one another. But what else is possible to do within Vidya’s solution? Well, we asked our clients how they are using the VSP.

Janaina Albino and Stefany Batista, Delivery and Customer Success Team

From detecting corrosion to operating with ease

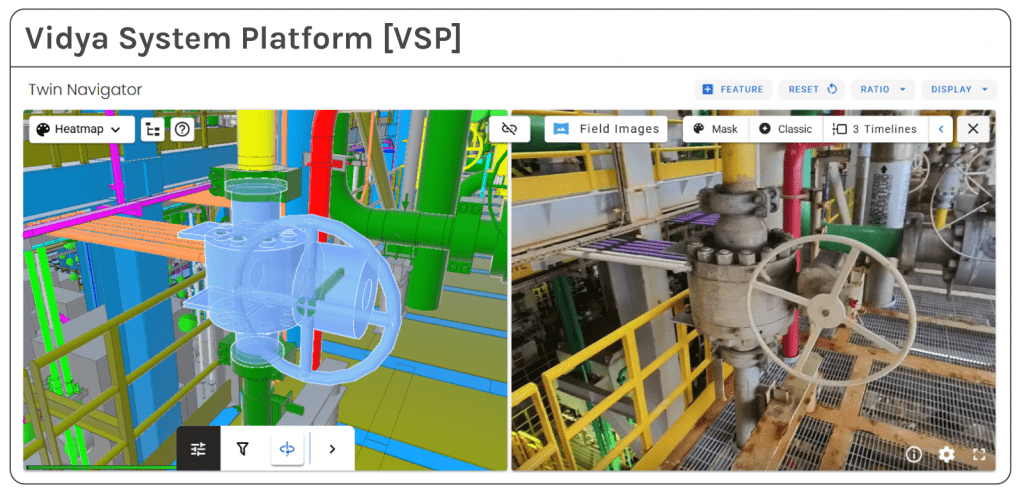

Born as a corrosion-targeted solution, the scope and capabilities of the VSP kept evolving into a broader operational intelligence environment. Through its integration of 3D modelling, 360° imaging, and analytics capabilities, the platform transcends the limitations of remote inspections. Instead of serving as a diagnostic tool restricted to identifying degradation, it now functions as a digital interface that consolidates inspection, maintenance, and planning activities into a single operational view.

Why Vidya sets the standard for corrosion assessments

Trained on large datasets of industrial images, Vidya Technology developed AI models capable of recognizing corrosion patterns with high precision even under poor lighting or in environments where human visibility is limited. This enables the automation of General Visual Inspection (GVI), significantly reducing the time and exposure required for manual assessments.

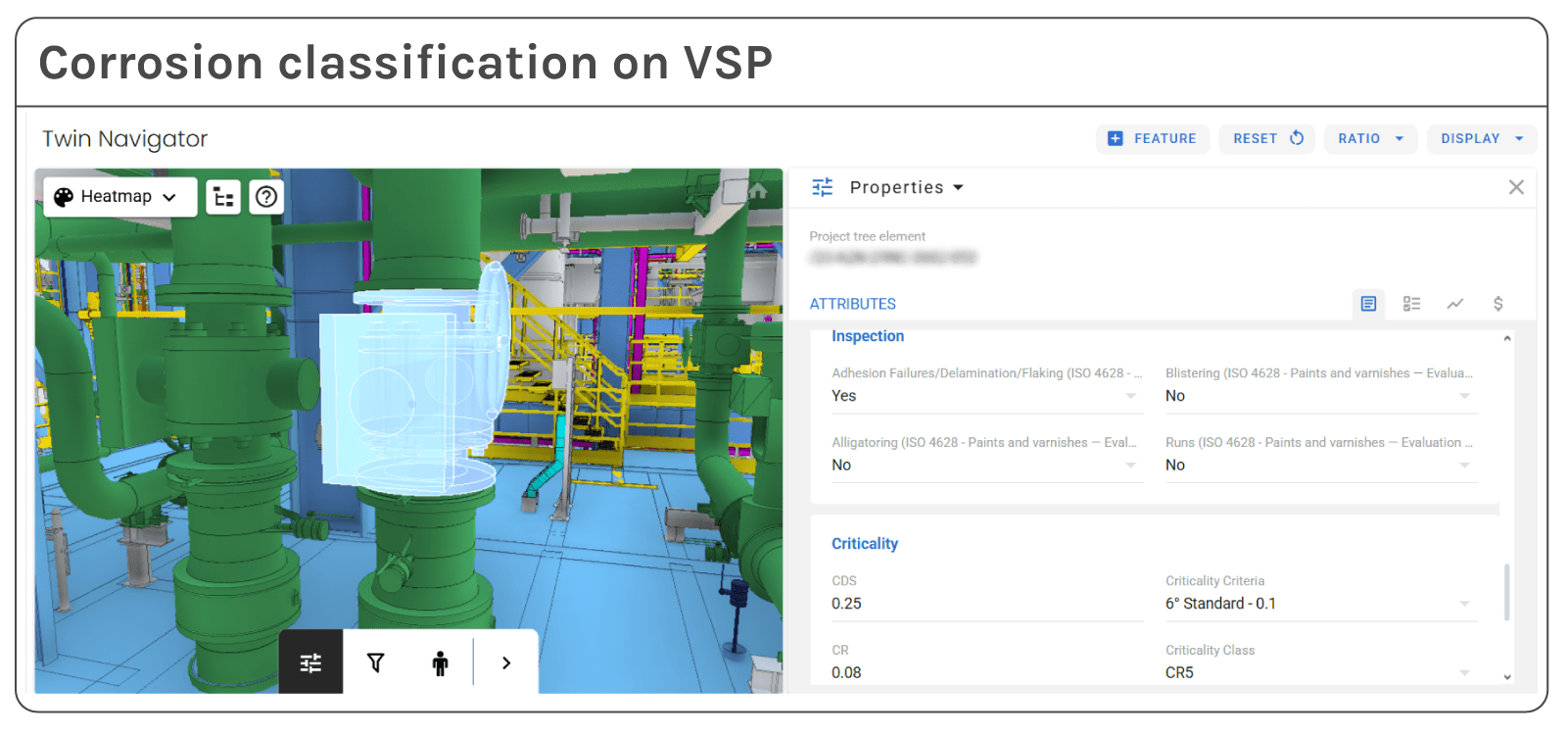

Beyond detecting corrosion, the system classifies anomalies according to standards such as ‘’ASTM D610’’ and ‘’ISO 4628’’, mapping their location, extent (m²/ft²), and forecasting degradation over time. These predictive insights help engineers anticipate risks, prioritize interventions, and avoid unnecessary shutdowns.

However, the breakthrough goes beyond identification and prediction. Vidya created a structured digital environment where all corrosion information (imagery, measurements, classifications, and historical data) is managed and centralized. In these conditions, the technology chosen to support this holistic view was the Digital Twin, which provides both the visual layer and the data aggregation framework needed for a complete understanding of asset conditions.

This Digital Twin architecture became the foundation not only for corrosion management, but for broader operational analysis. As users began interacting with a unified visual-data environment, they repurposed the same infrastructure to solve other challenges, from planning field activities to analyzing process risks and coordinating shutdowns. What began as a corrosion-focused Digital Twin evolved into a multipurpose environment for operational intelligence across the asset lifecycle.

Despite that, automating General Visual Inspections (GVIs) with AI corrosion detection wasn’t enough as the need for higher levels of digital maturity grew. Industrial operators began seeking platforms capable of supporting not only detection but also the planning, coordination, and execution of field activities. Thus, the capacity to centralize visual, structural, and analytical data has become indispensable.

How VSP users are repurposing Vidya’s software

As the VSP offers a holistic software, users assign their own custom purposes to the platform. The same digital infrastructure that enables corrosion monitoring is now being leveraged for different uses, effectively transforming it into a hub for operational intelligence. What follows are examples of how clients are adapting the system to meet their specific challenges, repurposing it in ways that redefine how industrial operations are visualized, analyzed, and executed.

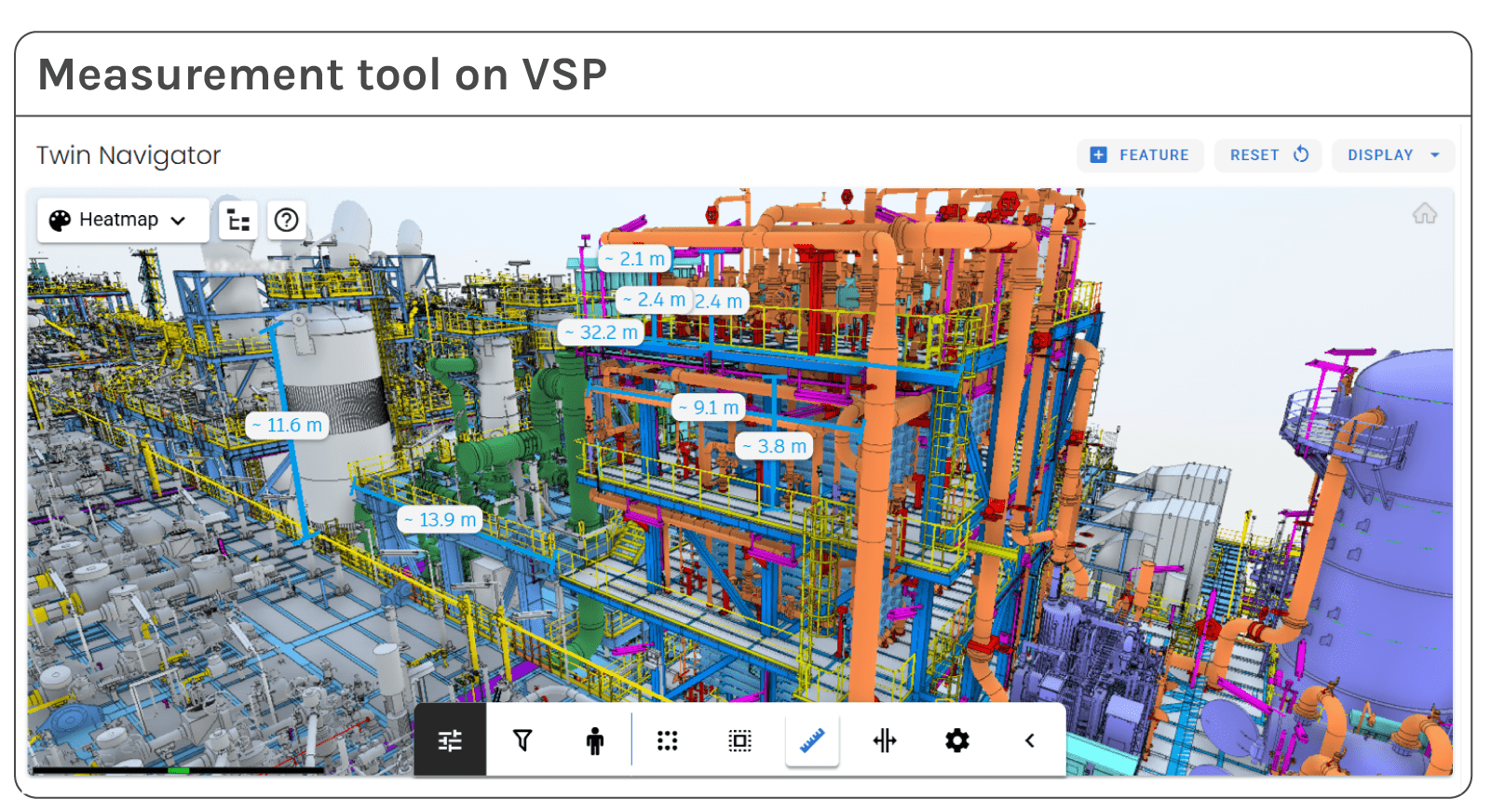

Online field measuring for execution outlining

VSP users from different operators reported that they use Vidya’s system to delineate field projects by combining and synchronizing the facility’s 3D model and 360° imagery tools. With this capability, operations gain full visibility of the facility layout, supporting plant modifications or the movement of loads and structures. Thus, the platform facilitates resource planning through integrated dashboards and automated reporting, allowing comprehensive analysis of field requirements and project progress.

To support operational activities, users also indicated that they leverage the system’s imagery and 3D models to outline the execution of coating areas, including surface measurements and element locations, helping identify optimal routes with minimal effort and ensuring safer and more efficient load handling. For this purpose, the measuring tool can be used to calculate distances between equipment passages, while combined filtering options make it possible to isolate specific structures, locate components, and determine total paintable surface area directly from the system environment.

Once the digital mapping is complete, users can generate detailed reports directly from the platform. These reports consolidate all relevant measurements and include drawings of scaffolding structures that must be assembled to access specific equipment, with each element precisely dimensioned. The same data feeds into dashboards that track field progress and resource allocation, ensuring a smooth transition from planning to execution.

But what does this look like in practice? First, open the 3D model and locate the desired equipment. Then, measure the distance between paths or elements with the ruler tool. Finally, prepare a report containing all the necessary information for those who will perform the work in the field. This report contains drawings of the scaffolding that must be assembled to hoist the equipment, with precisely calculated and detailed measurements.

“I can carry out checks and inspections without needing a single POB in the field. With my analysis and planning, I support C&M, maintenance, cargo handling, and integrity.” — Production Engineer

Planning facility shutdowns

VSP users also reported using Vidya’s platform to plan and coordinate facility shutdowns with greater precision. By integrating element location, material type, fluid data, photos, and corrosion information, the system enables teams to determine whether shutdowns are required and to plan them efficiently when they are.

Through the platform’s 3D model and 360° imagery tools, users gain complete visibility of the plant environment, allowing them to locate and assess the specific areas where interventions will take place. This visual context helps operators understand the operational conditions of each element, facilitating better sequencing of maintenance tasks and resource distribution across different areas.

To support this process, users combine the system’s visual and analytical capabilities to generate detailed mappings of the shutdown scope. Data from 3D positioning, imagery, and corrosion reports are consolidated within the system and can be complemented with dashboard analyses, producing comprehensive deliverables that guide planning and execution.

Based on these analyses, activities are planned and coordinated, with specific tasks delegated to other areas such as construction and maintenance, load handling, and integrity management, providing ongoing visibility into task progress, schedule adherence, and resource allocation throughout the shutdown process.

In practice, the workflow is straightforward: open the 3D model, identify the affected equipment, review the associated maintenance and material data, and generate the work order scopes detailing the required interventions. After the procedures are prepared, users define the most efficient path and activity sequence to minimize shutdown time and unnecessary movements. These coordinated steps ensure that every shutdown is carried out safely, efficiently, and with full situational awareness.

Process and Risk Scenario Analysis in the Unit

VSP users also reported using the system to assess process and risk scenarios across operational units. The platform supports the identification of deviations, potential failures, and improvement opportunities within safety and operational processes.

With this capability, teams can visualize the unit’s layout and pinpoint areas where safety equipment checks or process validations are needed. It functions as a support tool for analysis, allowing them to evaluate the feasibility of field changes and verify whether existing safeguards meet operational requirements.

In addition to direct assessments, the interviewed users said they receive internal requests related to failures or improvement opportunities. Using the VSP, they check field conditions and support risk analysis by HSE professionals or engineers. Once the verification is complete, the corresponding scope and identified conditions are shared with the field team, who confirm these conditions and proceed with approval for implementation.

Audit trail of decisions and interventions

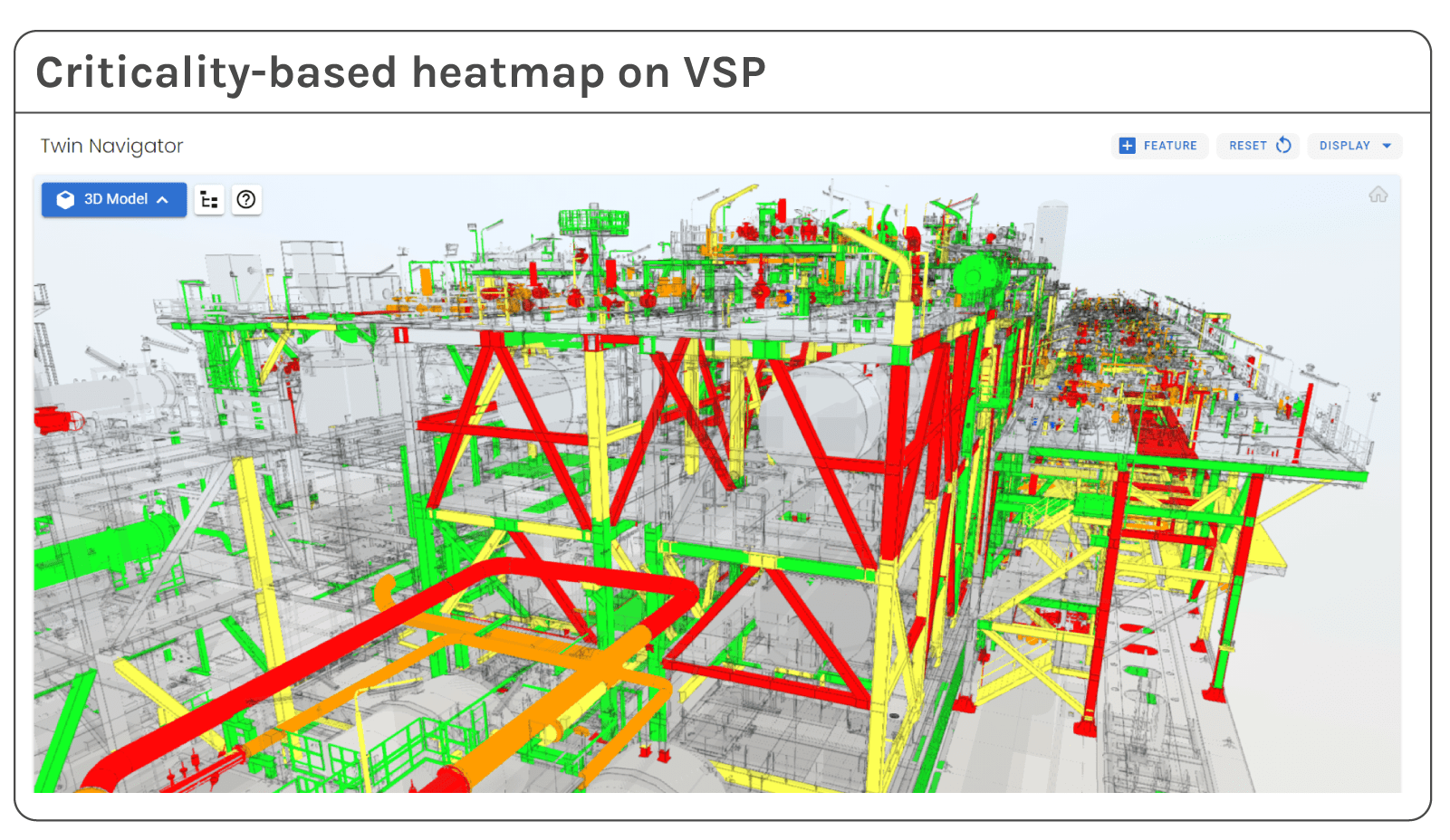

To reduce the administrative burden during data retrieval or third-party inspections, users said they leverage the platform to store digitized records of inspections, tests, and operational history. Using Kanban boards, heatmaps, resource availability dashboards, and KPI tracking, teams can plan collaboratively, delegate field work, allocate tasks based on their priorities, and keep execution aligned with strategic goals. In this context, activities are traceable, auditable, and fully linked to asset conditions and intervention histories.

In this integrated context, activities become auditable with a full link established between the intervention history and the current asset conditions. This setup ensures full traceability across the entire integrity process, allowing users to know exactly who performed each task, when it was done, and why, which is crucial for supporting compliance efforts and facilitating accurate root cause analysis. In other words, the VSP enables comprehensive work management by consolidating inspection, maintenance, and engineering activities into a unified digital environment.

This digital thread is particularly critical for tracking the lifecycle of defects. The platform registers the evolution of an anomaly’s treatment from the moment of detection until its final resolution. This historical data provides the evidence needed for inspection bodies (such as SPIE) to determine whether an issue has been fully resolved or if it requires re-inspection or further maintenance, such as protective painting. Ultimately, this repurposing of the VSP ensures that every anomaly is mapped, prioritized, and addressed with a clear mitigation plan, closing the loop on industrial integrity.

Conclusion

These diverse applications prove that the VSP has outgrown its original definition as a mere inspection tool. By allowing the platform to absorb the logic of multiple disciplines, clients have turned a corrosion database into a living operating system for their industrial operation. This user-led evolution highlights a critical reality: in a complex industrial environment, the most valuable technology is not the one that strictly dictates a workflow, but the one that provides a unified context where engineering, maintenance, and compliance can finally speak the same language.

![Cover Beyond corrosion detection: How is Vidya’s System being used? Image of a woman using Vidya System Platforms [VSP] on a tablet.](https://vidyatec.com/wp-content/uploads/2025/11/1-capa-blog-CS@2x.png)