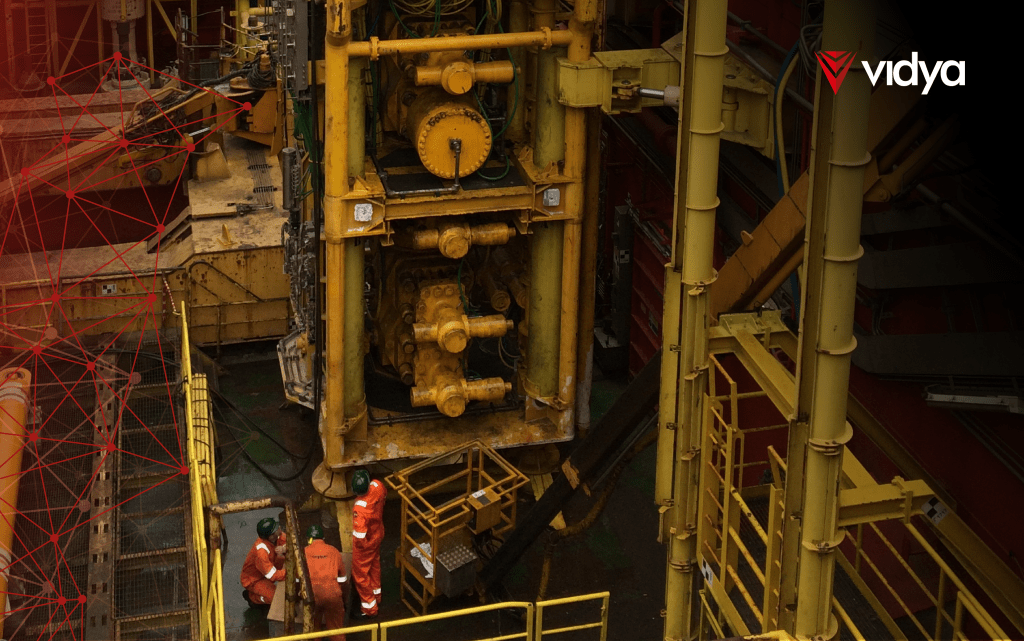

A 2011 study by IHS Cambridge Energy Research Associates reported that approximately two-thirds of global daily average oil production comes from brown fields and that the percentage is increasing over time. Indeed, it’s evident that mature fields have become a fundamental piece of the petroleum exploration sector, but what exactly are mature fields?

According to Parshall (2012), brown fields, also known as legacy fields, are defined by years of production and aging infrastructure. Indeed, for a field to be considered brown, it had to produce more than 50% of its established proved plus probable resource estimates or have produced for more than 25 years. In this context, why would any oil and gas industry adopt an aging facility for extracting resources?

Why adopt brown fields to extract resources?

Usually, oil and gas operators offer brown fields when production capacity starts to decline. Thus, these facilities are acquired through concessions with the previous operator, which include operating fees and payments made to the facility’s owner. And, while exploration for new reserves presents greater production potential, they still require a previous mapping and operability study of the targeted region, which can be expensive and time-consuming. In this scenario, brown fields are a compelling counterpoint by operating in established facilities, showcasing several benefits, including:

Economic Advantages

Compared to exploring and developing entirely new oil and gas fields, utilizing existing infrastructure in a mature field demonstrates reduced costs. While the infrastructure is already in place, companies that adhere to brown field exploration have lower costs with upfront investments and skip a pre-operation phase, that regularly involves securing all necessary permits and determining the ideal location and target depth for production. This enables companies to capitalize on a known resource with significantly reduced upfront investment while minimally adapting to new operating conditions.

Proven capacity

While every offshore oil field presents declining production rates over time, it possesses proven capacities that cannot be ignored. In this sense, the verifiable potential of brown fields lies in their well-understood geological characteristics, established infrastructure, and operational data accumulated over the years. Extensive production history generates years of data collection, capitalizing on the knowledge gained from producing these fields for decades. Besides that, there is a proven capacity for extraction, since platforms, pipelines, and processing facilities can be leveraged from the past user. On the other hand, new operating fields haven’t tracked records of production capabilities and Asset Integrity.

Sustainability

As the global energy demand continues to grow, revitalizing mature fields can be a sustainable and cost-effective alternative by extending the asset’s productive lives. In this context, reactivating existing infrastructure reduces the environmental footprint associated with developing entirely new production sites. By leveraging existing data and reusing drilling sites and facilities, brown field exploration leads to less resource waste and enhances HSE standards (Health, Safety, and Environmental) compliance.

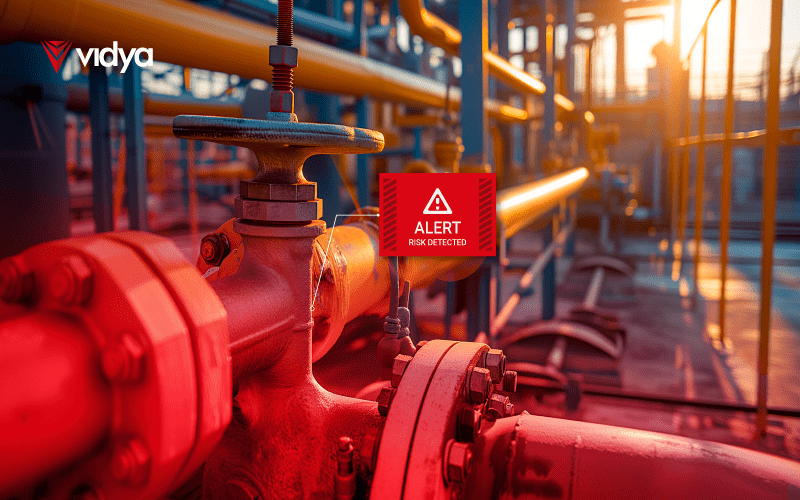

Despite adopting mature fields for oil and gas extraction offers several advantages, operators still have to deal with an aging infrastructure that requires special care. According to the article ‘’Offshore Oil and Gas Installation – Aging and Life Extension’’, when equipment comes closer to the end-of-life stage, the safe operating limits are near, requiring advanced inspection techniques at closer intervals to determine fitness for purpose and major repairs, while deterioration is accelerating. For this reason, companies that explore brown fields must consider structure revitalization and new optimized methods to manage asset integrity.

The challenges of exploring brown fields

According to the article ‘’Technical and Non-technical Challenges of Development of Offshore Petroleum Reservoirs: Characterization and Production’’, safe, reliable, and efficient development of offshore hydrocarbon fields is even harder to achieve in aging reservoirs. While the economic benefits of existing infrastructure and proven reserves are undeniable, these advantages come at the cost of navigating through inherently risky environments, aging infrastructure, and diffused data.

Knowing that mature fields are often acquired through concession agreements from previous operators, technical documents, prior reports, and testing data are scattered across many datasets, hindering the development of a holistic understanding of the equipment’s accurate condition. Indeed, new operations receive extensive activity backlogs regarding Asset Integrity from the previous operators that require detailed validation and prioritization processes.

And, regardless of industrial operations generating gigantic amounts of data, managing them from various sources can be a daunting task. In this context, mature field operations need to cross-check the maintenance backlog to revitalize integrity across various departments, such as SPIE, C&M, and Naval Engineering, among others. According to Forbes, despite industries collecting vast amounts of data, 60% to 73% of this data has yet to be successfully used for any strategic purpose. This scenario leads to a lack of awareness surrounding Asset Integrity, resulting in an incomplete perspective on the facility’s degradation state and hazard chances.

Transforming Brown Oil Fields with AI

According to The Journal of Petroleum Technology, once considered as being on the brink of abandonment, aging reservoirs are proving to be valuable assets as innovative recovery techniques of re-envisioning these fields are transforming them into reservoirs of opportunity. In these conditions, revitalizing these fields can be a cost-effective way to meet global energy demands, extending asset productive lives and offering significant opportunities to expand worldwide reserves. But how can this be done optimally?

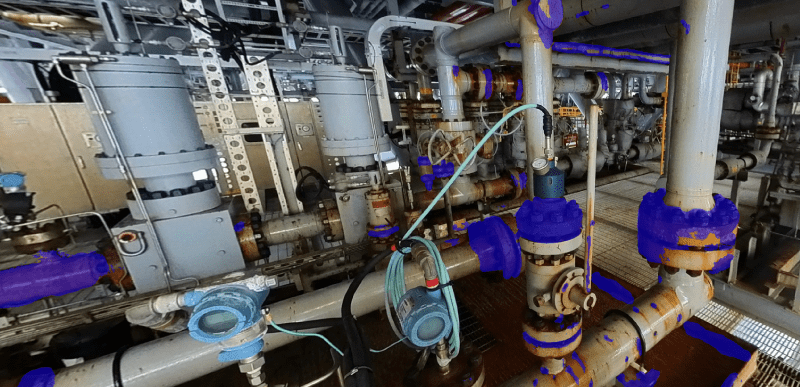

Digital Fabric Maintenance

Within this context, deeptech solutions are helping industries manage the legacy integrity notes associated with brown fields. The Digital Fabric Maintenance, a Vidya Technology application, autonomously identifies asset anomalies. It integrates Artificial Intelligence, 3D environments, Reality Capture, and Spatial Computing to transform field images into valuable integrity outputs for maintenance planning accuracy. Additionally, this AI application provides a holistic perspective on Asset Integrity Management, supporting offshore operations with AI-driven insights, while strictly adhering to the company’s inspection standards. Thus, this technology allows industries to fulfill the assessment of corrosion and structural anomalies optimally, delivering results in 30 days or less, such as:

- No need for onboard inspectors, anomalies are identified automatically by AI based on reality capture data

- Agility and precision in the coating and structural integrity management process

- Savings in POB, Rope Access activities, rework, and M/H planning for coating activities

- Traceable, auditable, and contextualized integrity data on 3D environment (+heatmaps)

- Prediction of corrosion degradation status over time through AI models