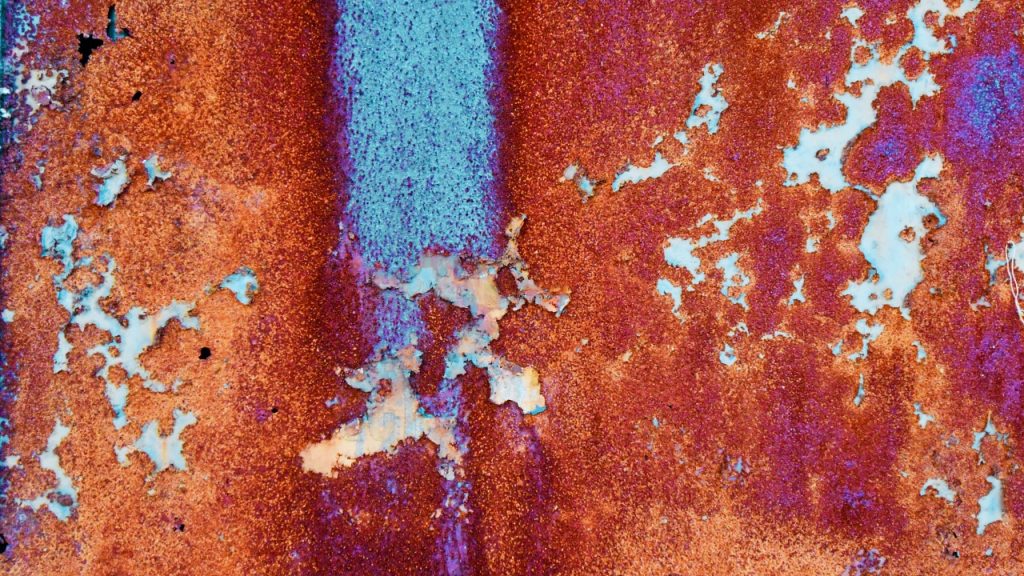

In the realm of asset integrity management, a meticulous approach to internal corrosion monitoring emerges as an indispensable facet. Corrosion, accounting for a substantial share of failures and maintenance costs in the process industries, demands vigilant attention from integrity and maintenance managers.

This degradation mechanism, prevalent in industries such as refineries, petrochemicals, FPSOs, and other plants, necessitates a systematic monitoring approach.

Understanding the critical role of internal corrosion monitoring in the seamless operation of industrial plants is paramount.

The economic implications of component replacement and structural recovery far surpass the costs associated with corrosion prevention and control. Consequently, the implementation of internal corrosion monitoring plans becomes imperative for processes deemed critical, enabling the timely detection of corrosion rates that could jeopardize the integrity of pipes and equipment.

Vidya’s approach to internal corrosion monitoring

Addressing this inherent challenge, Vidya has engineered a cutting-edge solution: the ER Wireless Corrosion Monitoring Sensor. This innovative technology empowers industries with precise monitoring capabilities and seamless real-time data access.

The ER Data Logger, boasts compatibility with standard market connections, facilitating easy installation in a variety of pipelines for internal corrosion monitoring purposes.

Distinguishing itself from conventional options, the ER Data Logger possesses an autonomous capability to establish communication between the field and the database through a wireless HART mesh network. Connectivity with the dedicated app via Bluetooth enables users to access real-time readings, define time intervals for data collection, and seamlessly perform firmware updates.

Adding to its functionality, the device is EX-certified, ensuring its operational reliability even within specific and challenging conditions.

Features:

Communication via Wireless HART compatible with the IEC 625912591 standard

EX ia IIC T4 Ga, Tamb = -20ºC to 60ºC Protection IP66

Up to 700 thousand ER measurement could be stored

Conclusion

Embark on a journey towards enhanced corrosion management with Vidya’s cutting-edge technology. Connect with our experts today to explore how our solutions can fortify the integrity of your industrial assets.

Click to contact us and discover the transformative impact of Vidya’s corrosion monitoring solutions on your operations.