In industrial environments where downtime costs millions and safety is non-negotiable, simply linking systems is not enough. What truly matters is turning fragmented, raw information into structured intelligence that supports decision-making in real time.

When done right, integration platforms can become much more than data pipelines. They provide the context, structure, and visibility that enable teams to focus on what is critical, anticipate risks, and execute with confidence. In this context, before understanding why most integration platforms fall short of expectations, it is important to define what an integration platform is.

What is an integration platform?

An integration platform refers to a software environment designed to connect different systems, applications, and databases so that information flows seamlessly between them. In practice, these are SaaS (Software as a Service) solutions offered by specialized providers, promising a centralized layer of connectivity for enterprise resource planning (ERP), computerized maintenance management systems (CMMS), PIMSs (Plant Information Management System), EDMSs (Electronic Document Management System), inspection tools, and other critical software.

While the promise of breaking down silos and consolidating information is appealing, the reality is more complex. The true challenge isn’t simply connecting systems, but ensuring the data is meaningful, contextualized, and usable for decision-making in real-world operations.

Challenges of embracing integration platforms

Although integration platforms are often presented as a straightforward solution, the reality of deploying them in industrial contexts is far from simple. Beyond the technical hurdles, organizations face cultural, operational, and strategic challenges that limit adoption and dilute value. The article “A Systematic Review of Asset Integrity and Process Safety Management Sustainability for Onshore Petrochemical Installations” stated that the challenge for industries is to embrace the benefits of integration platforms while simultaneously developing robust strategies to mitigate the emerging risks and ensure the safety and integrity of their processes and assets. In this context, three of the most pressing challenges are:

1. Organizational Resistance

Employees who are deeply familiar with existing systems may view new platforms as unnecessary disruptions. Indeed, embracing change isn’t easy, especially if employees are accustomed to established processes and systems. This resistance can stem from a fear of the unknown, a lack of understanding of new technologies, or concerns about job security. Without proper change management, communication, and training, adoption rates stay low, and the platform fails to reach its potential. According to McKinsey, engaging senior roles and technology-innovation managers is key to building capabilities for the entire workforce, bridging potential gaps between the traditional and digital parts of the business.

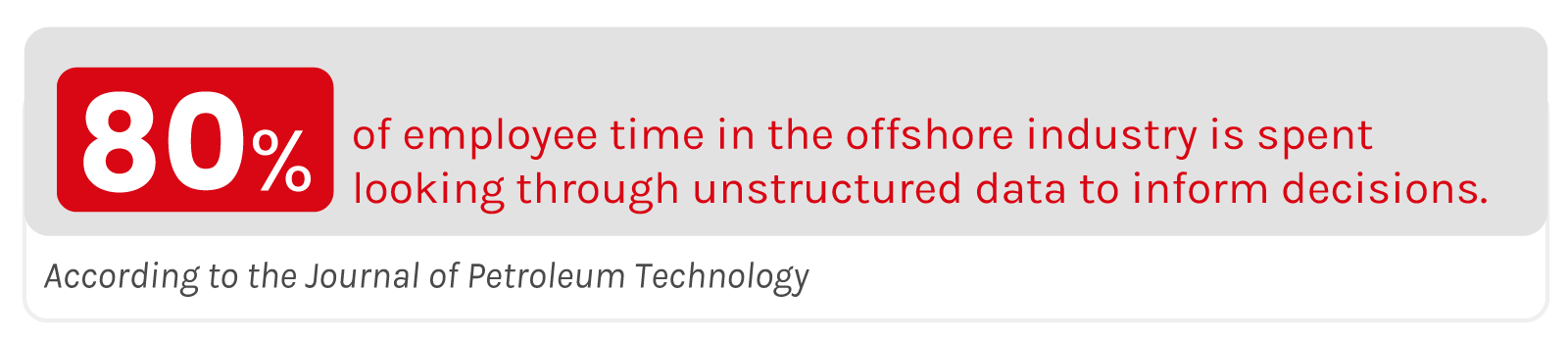

2. Data Overload

Operational data is often unstructured, unprocessed, untreated, and presented in various forms as spreadsheets, reports, on-premises systems, or cloud systems. The Journal of Petroleum Technology reported that 80% of employee time in the offshore industry is spent looking through unstructured data to inform decisions. Integration platforms promise to solve this, but unless data is properly contextualized and accessible, the problem persists just within a new interface.

3. Innovation Bottleneck

Large corporations often move slowly when it comes to change. The bureaucratic nature of these companies often stifles creativity and slows down the innovation process. Decision-making layers, risk-averse attitudes, and a focus on short-term results can hinder the development and implementation of innovative digital solutions. In this context, a global survey by IFS revealed that only 17% of energy and utility companies have completed their digital transformation journeys. The survey points to a lack of clear leadership as one of the main obstacles, in addition to a shortage of the skills and knowledge needed to effectively implement these technologies.

How integration platforms add value to industrial operations

The promise of integration platforms goes beyond simply connecting different software systems. Their real value lies in creating a structured environment where data, assets, and processes can be understood in relation to one another. By providing a holistic view of operations, these platforms help industrial companies shift from reactive practices to more informed, proactive strategies. Three areas in particular highlight how integration platforms can drive meaningful improvements: data contextualization, asset criticality and risk analysis, and inspection management.

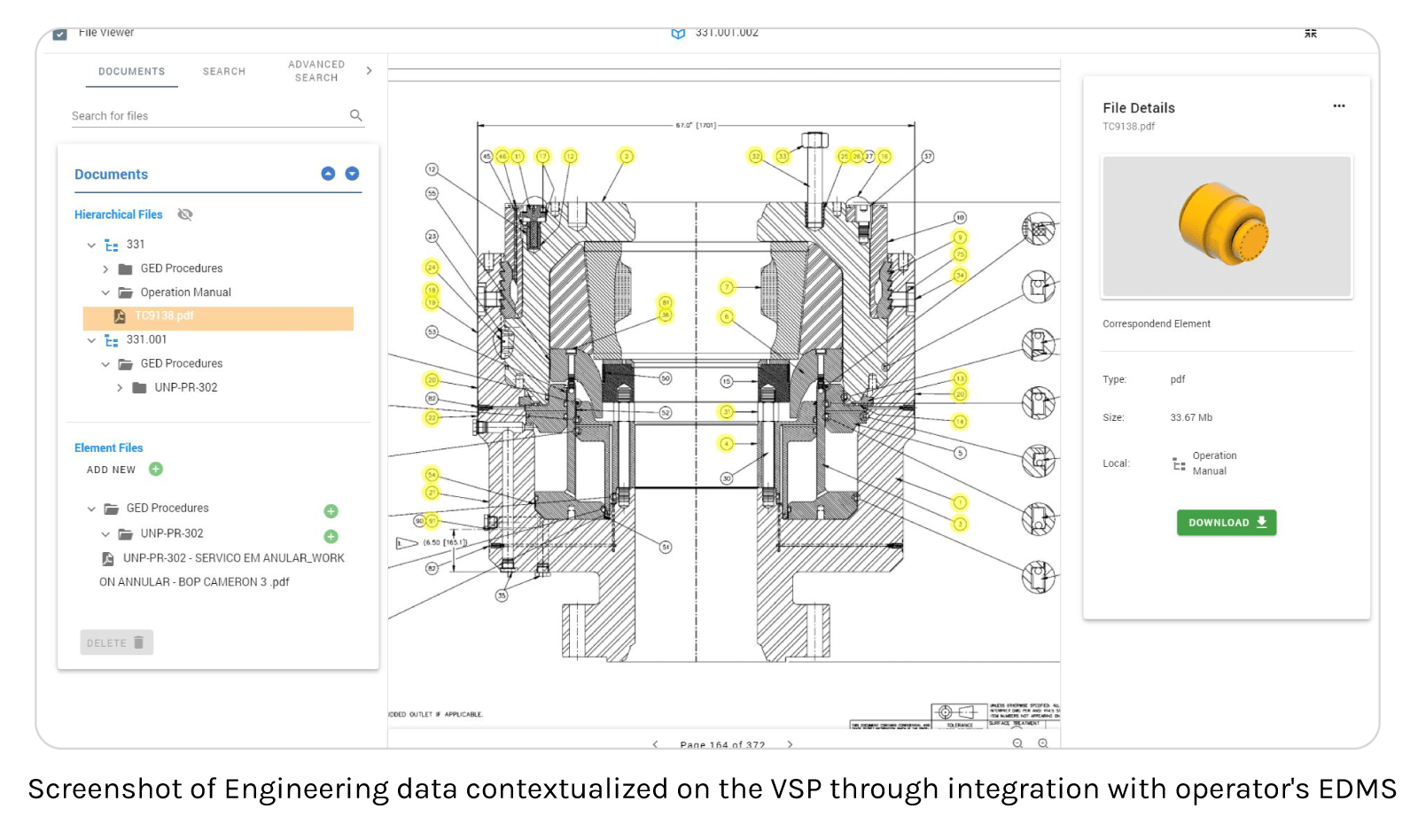

1. Data contextualization

Vast amounts of raw data are constantly generated, yet much of it remains fragmented, unstructured, or locked away in legacy systems. Data contextualization is the process of linking these different sources so that information is not only gathered but also placed in the right operational context. In other words, it’s about understanding what the data means, not just what the data says. Without a way to correlate engineering data, field activity reports, and operational inputs, the information often lacks the context needed to support real decisions.

Integration platforms address this by converting raw engineering inputs into processed, usable datasets. They allow companies to bridge historical data with current operational information, creating an environment where data points are collected and related to their referring equipment, processes, and operational requirements. This provides the foundation for more advanced applications, from digital twins to predictive analytics.

2. Asset Criticality and Risk Analysis

Integration platforms also add value by linking asset data with risk models, allowing companies to identify which risks are most critical to operations and where failures would have the greatest impact. This makes it possible for decision-makers to allocate resources more effectively and move from reactive maintenance toward risk-based strategies. Accordingly, a Verdantix Survey stated that 61% of the interviewed industrial operators plan to increase investments in operational risk information systems.

3. Inspection management

Inspection management refers to the way companies plan, execute, record, and follow up on inspections across their assets. Traditionally, this process involves scattered spreadsheets, handwritten reports, and disconnected software tools. The result is duplicated work, missing information, and limited visibility for decision-makers.

An integration platform changes this dynamic by serving as a single environment where inspection data can be scheduled, captured, stored, and monitored in a structured way. Instead of treating each inspection as an isolated task, these platforms allow findings to be tracked over time and compared across assets.

Limitations of integration platforms

Even when organizations overcome cultural and operational barriers, integration platforms still face inherent limitations. According to the article “A Systematic Review of Asset Integrity and Process Safety Management Sustainability for Onshore Petrochemical Installations”, these limitations include:

1. High implementation costs

Integration platforms require significant upfront investment in licensing, customization, infrastructure, and employee training. For many companies, especially in large-process industries, these costs can be difficult to justify without a clear path to measurable returns. The promise of streamlined data flows and improved decision-making often clashes with the financial reality of tight budgets and competing priorities.

Moreover, implementation doesn’t end with deployment. Ongoing support, updates, and scalability add to the total cost of ownership. If adoption rates remain low due to organizational resistance, the platform risks becoming an expensive tool with limited impact, ultimately failing to deliver the expected ROI (Return on Investment) and creating skepticism about future digital initiatives.

2. Legacy system integration

Industrial facilities often rely on systems that have been in place for decades. These legacy applications may not be designed to connect with modern integration platforms, making the process technically complex and resource-intensive. Attempting to integrate such systems can lead to disruptions, delays, and hidden costs that undermine the efficiency gains the platform was meant to provide.

3. Data synchronization

Bringing multiple systems together is only the first step; keeping them synchronized is far more challenging. Data can change in real time across different applications, and ensuring that these updates are reflected consistently within the integration platform requires more than basic connections: it demands disciplined DataOps practices. Without them, discrepancies arise, leading to duplicated records, outdated insights, and flawed decision-making.

A critical element of this is the use of APIs (Application Programming Interface), which are sets of rules that allow different software systems to communicate securely with one another. However, APIs themselves introduce new challenges: how are integration pipelines and their health monitored? What happens when an API fails? If these connections are not actively tracked, organizations risk working with outdated records, duplicated entries, or incomplete insights.

In this context, DataOps methodologies emphasize observability, version control, and automated monitoring of data pipelines. For integration platforms, this means being able to trace every connection, confirm that data was updated at the last second, and quickly identify failures in the flow. Without such mechanisms, decision-makers may base critical actions on flawed information, undermining the very purpose of integration.

4. Cybersecurity

Every new integration point increases the digital footprint of an organization, widening its attack surface. By linking multiple systems and centralizing sensitive operational data, integration platforms can become targets for cyber threats. According to a report from ABI Research, one in four industrial enterprises had to halt operations due to a cyberattack temporarily. Thus, as companies adopt IoT devices, autonomous systems, and cloud web services, the attack surface for cyber threats expands significantly.

For this reason, managing this risk requires constant vigilance: regular security updates, penetration testing, access controls, and employee training. Industry standards such as ISO/IEC 27001 (information security management), ISO/IEC 27017 (cloud security), ISO/IEC 27018 (protection of personal data in the cloud), and SOC 2 (system and organizational controls for data security, availability, and integrity) are critical references for ensuring best practices.

Yet, cybersecurity is often treated as an afterthought, especially when companies are focused on achieving fast implementation. Without a strong security framework, integration platforms risk becoming liabilities, undermining both operational integrity and corporate trust.

Holistic Operational Management with a Data Centric Framework

The limitations of traditional integration platforms show a recurring pattern: they centralize data but rarely use it for a strategic purpose. Connectivity alone doesn’t solve the complexities of large-process industries; what is needed is an approach that aligns with how each industrial operation actually runs.

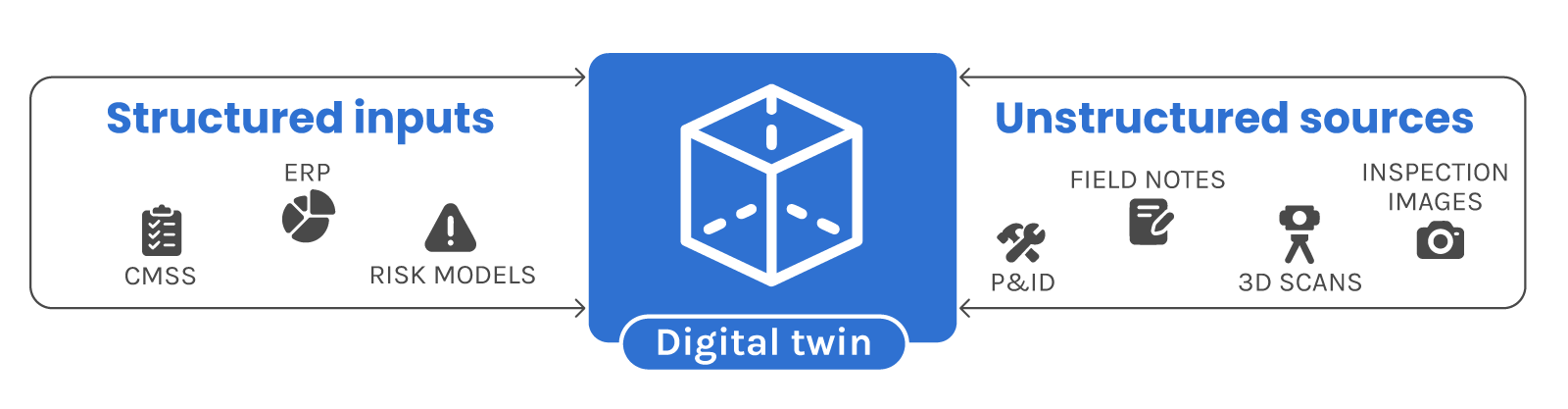

For this reason, Vidya, a global company in Asset Integrity and Performance Management for large-process industries, introduces a solution that ingests both structured and unstructured data and transforms them into a purpose-built framework, continuously adapting to the priorities, workflows, and realities of each operation.

![Vidya System Platform [VSP] demonstrating analytics data integration on the Digital Twin](https://vidyatec.com/wp-content/uploads/2025/09/6-Why-do-most.png)

Moving Past Connectivity Into Operational Clarity

Instead of working with fragmented reports or siloed BI dashboards or having to stack multiple operating systems, decision-makers interact with a single, unified environment that mirrors the real plant.

This means that integrity, maintenance, and process safety management are no longer treated as disconnected workflows. Every inspection record, maintenance activity, or risk assessment is correlated within the same digital backbone, making it possible to understand not just what is happening, but why it is happening and what it impacts.

By combining structured inputs (such as CMMS, ERP, and risk models) with unstructured sources (inspection images, field notes, P&IDs, 3D scans), the platform builds a dynamic Digital Twin that serves as the foundation of operations. Thus, integration pipelines are continuously monitored with tracked triggers, ensuring data integrity and reliability. This allows teams to clearly visualize cause-and-consequence chains, anticipate risks, and act decisively in environments where uncertainty is costly and safety is non-negotiable.

Balancing AI analytics and Human Expertise

To support the planning, access, validation, and reporting of industrial work, Vidya developed AI proprietary models so operations can extract accurate information directly from field assets, link asset tags with documentation and condition data automatically, integrate data from multiple sources, and accelerate anomaly detection and resolution.

Beyond Vidya’s own models, the system also supports the use of external AI services, whether developed by customers or available in the market, and can seamlessly plug in specialist AI models tailored to specific tasks. Through an AI agent orchestration platform, these different capabilities are unified within a secure environment that ensures controlled data access founded in Retrieval-Augmented Generation (RAG) and data ontologies.

This GenAI service acts as a host for specialized AI agents, designed to handle complex functions such as issue identification, predictive modeling, and even the creation of 3D heatmaps. By leveraging a domain-trained large language model (LLM), the platform coordinates these agents to optimize operations through the Digital Twin, providing an adaptable and scalable framework.

And, despite these capabilities, AI replacing human expertise shouldn’t be a concern. AI doesn’t just automate tasks; it questions long-standing practices and encourages teams to re-evaluate how things have been done.

It is common to think that AI might impact the most valuable resource that industries have, their human expertise. In this regard, the article ‘’Maintenance Problem Identification on Offshore Platforms Through Analysis of Maintainer Work’’ highlights that most on-site workers present different mitigation strategies for all sorts of maintenance events, generating different yet valuable perspectives on the work being done at the facility.

In these conditions, the AI supports operations by automating tasks and detecting anomalies, but detailed diagnosis and confirmation require human validation to ensure reliability. Thus, Vidya’s approach doesn’t force operations to adapt to technology; it is the Vidya System that adapts to your criteria. This way, operational management goes far beyond static reports and dashboards, becoming an interactive, visual, and intuitive process where AI supports every decision.

When Data Finds Its Meaning

Data is not just a byproduct of operations; it is a strategic asset. The real value of data is when it goes beyond storage and reporting to actively support operations by highlighting critical areas, making information visual, traceable, and contextual, and translating complex technical details into clear insights for decision-makers.

Even when industries already have structured processes in place, digitalization exposes gaps that would otherwise remain hidden. Incomplete inspection histories, inconsistencies between documentation and asset conditions, or unlinked risk factors are examples of blind spots that traditional systems often overlook. By correlating every data point within a unified backbone, the Vidya Platform reveals these gaps and makes them actionable.

This approach ensures that data is not static or fragmented but dynamic and connected, driving continuous improvement across integrity, maintenance, and safety. Instead of serving as a record of what has already happened, data becomes a living foundation for anticipating risks, prioritizing actions, and ensuring that operations remain reliable, efficient, and safe.

Conclusion

Furthermore, the real measure of an integration platform’s success is how effectively it empowers organizations to operate with clarity, agility, and resilience. Technology alone, however, is not a miracle solution; it requires time, input, and proper integration into workflows to generate real value. Each technology has its own implementation needs, and value only emerges when it is contextualized and adapted to the operation.

By aligning technology with the realities of industrial operations, companies can move past the limitations of fragmented tools and embrace a model where safety, integrity, and performance are managed as one. The future belongs to solutions that turn complexity into actionable understanding, and that future is already being shaped today.