Your corrosion treatment can’t end in a report

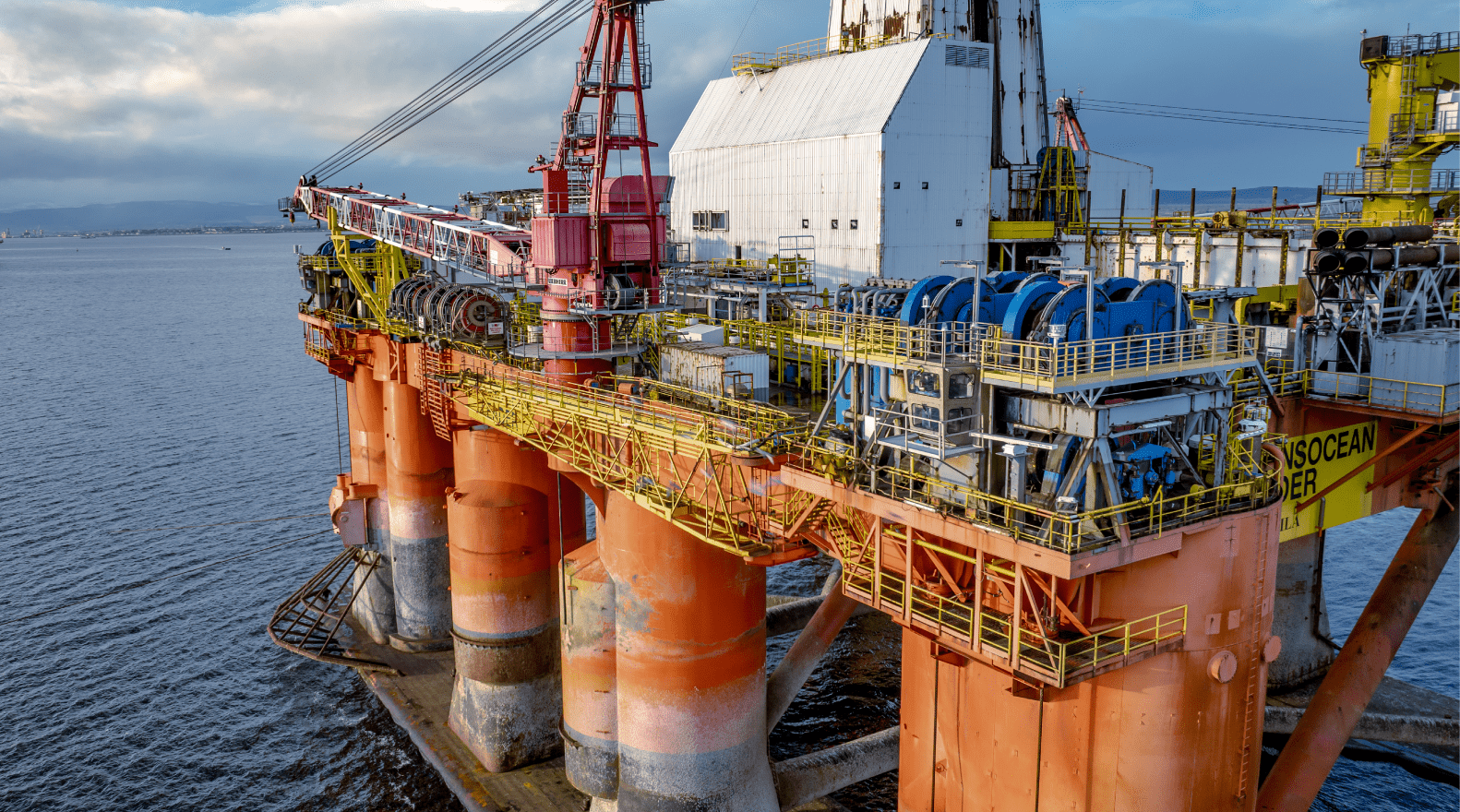

Experience the accuracy and efficiency of Digital Fabric Integrity. By leveraging reality capture and artificial intelligence, we provide a comprehensive corrosion assessment across your offshore oil and gas platform in under 30 days – all without the risks and costs associated with conventional methods.

It’s faster, safer, and smarter corrosion management.

Our company is trusted by:

Our company is trusted by:

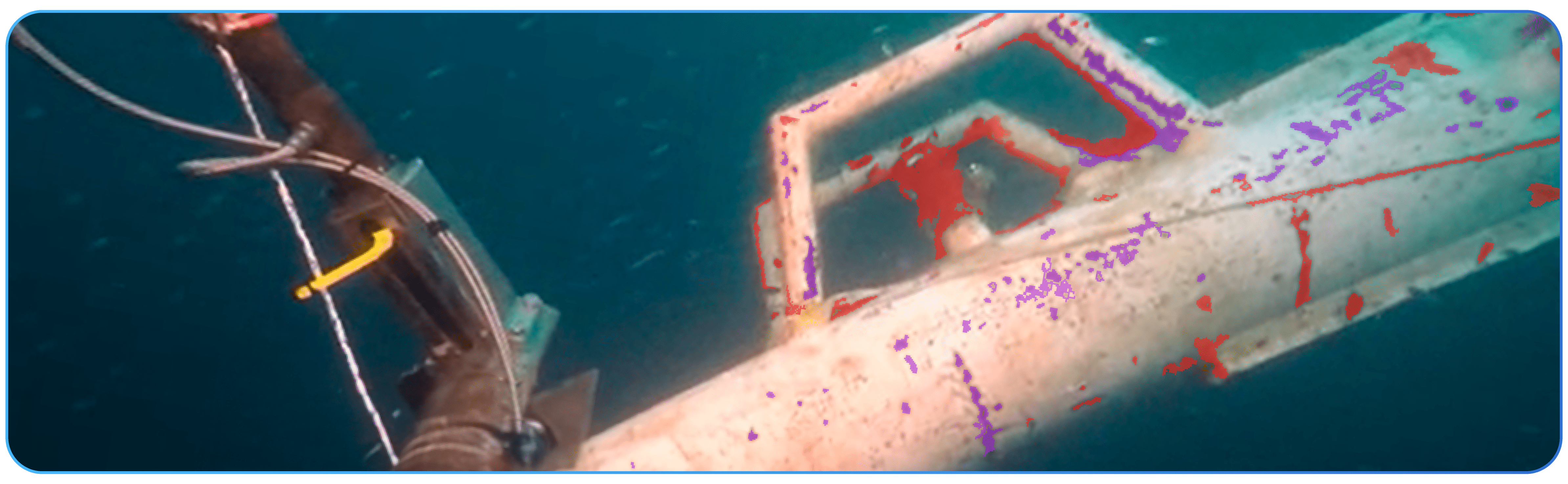

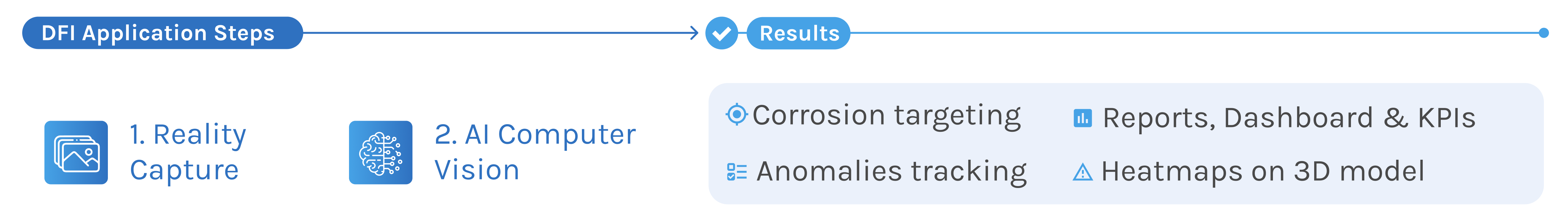

How does the Digital Fabric Integrity work?

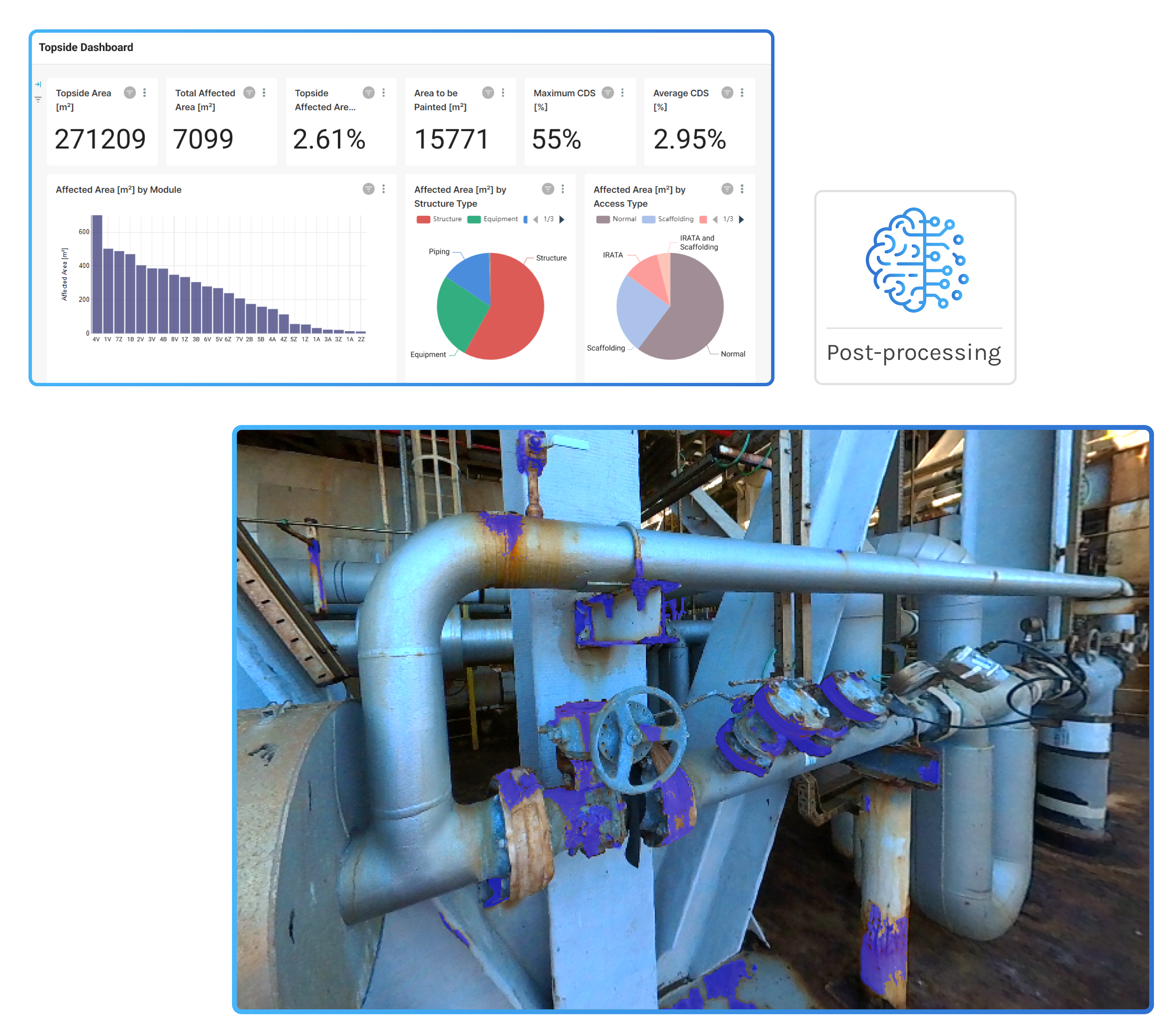

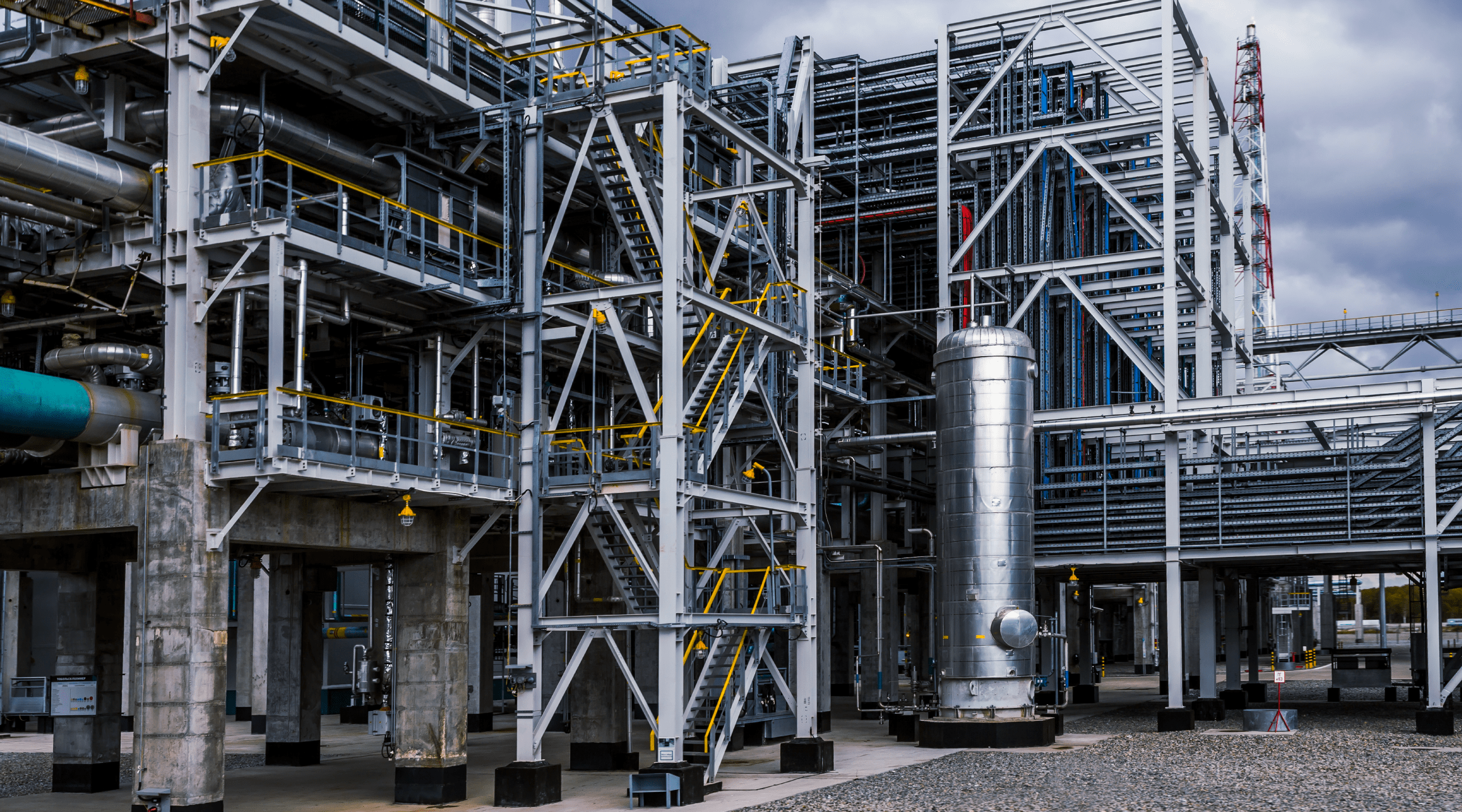

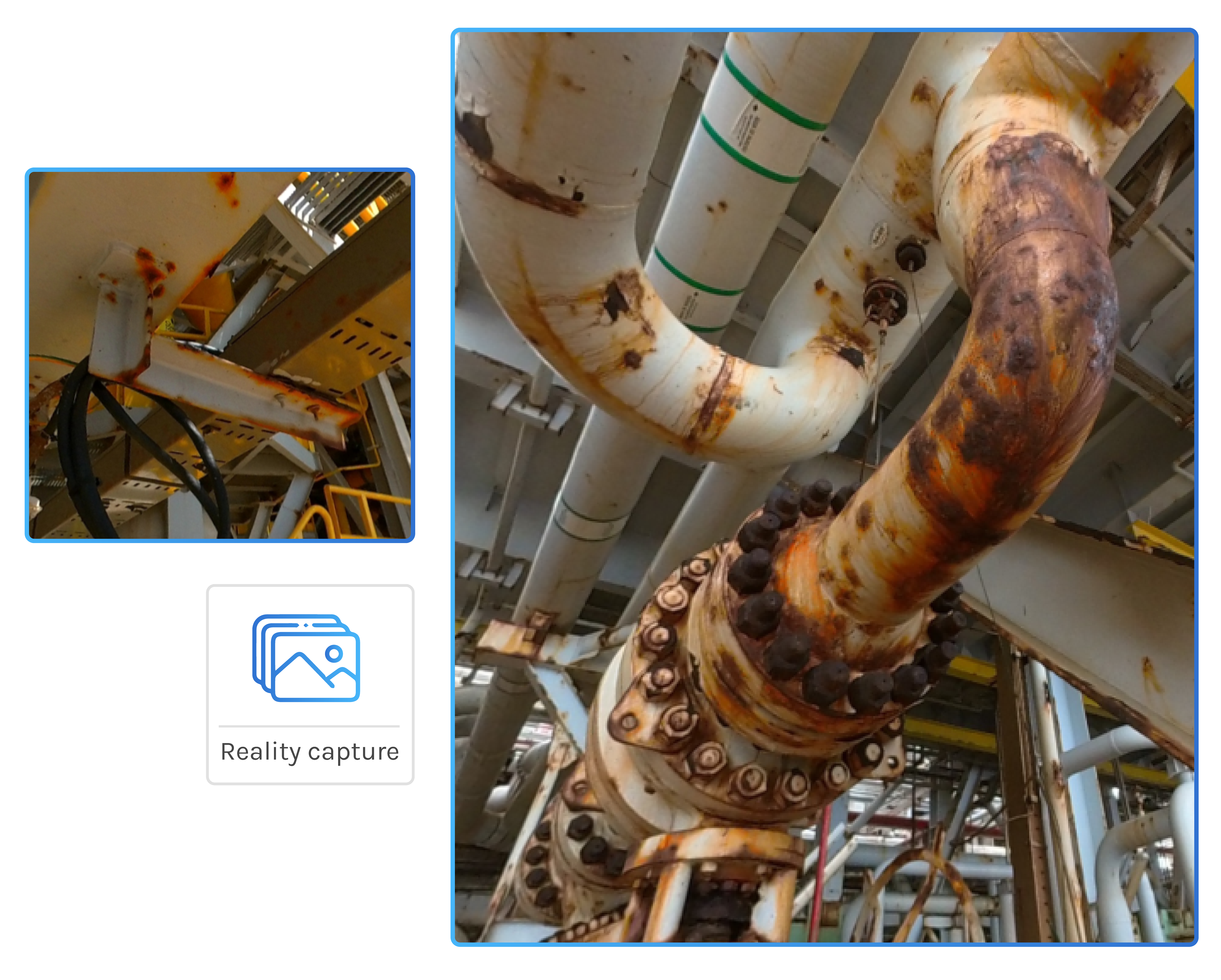

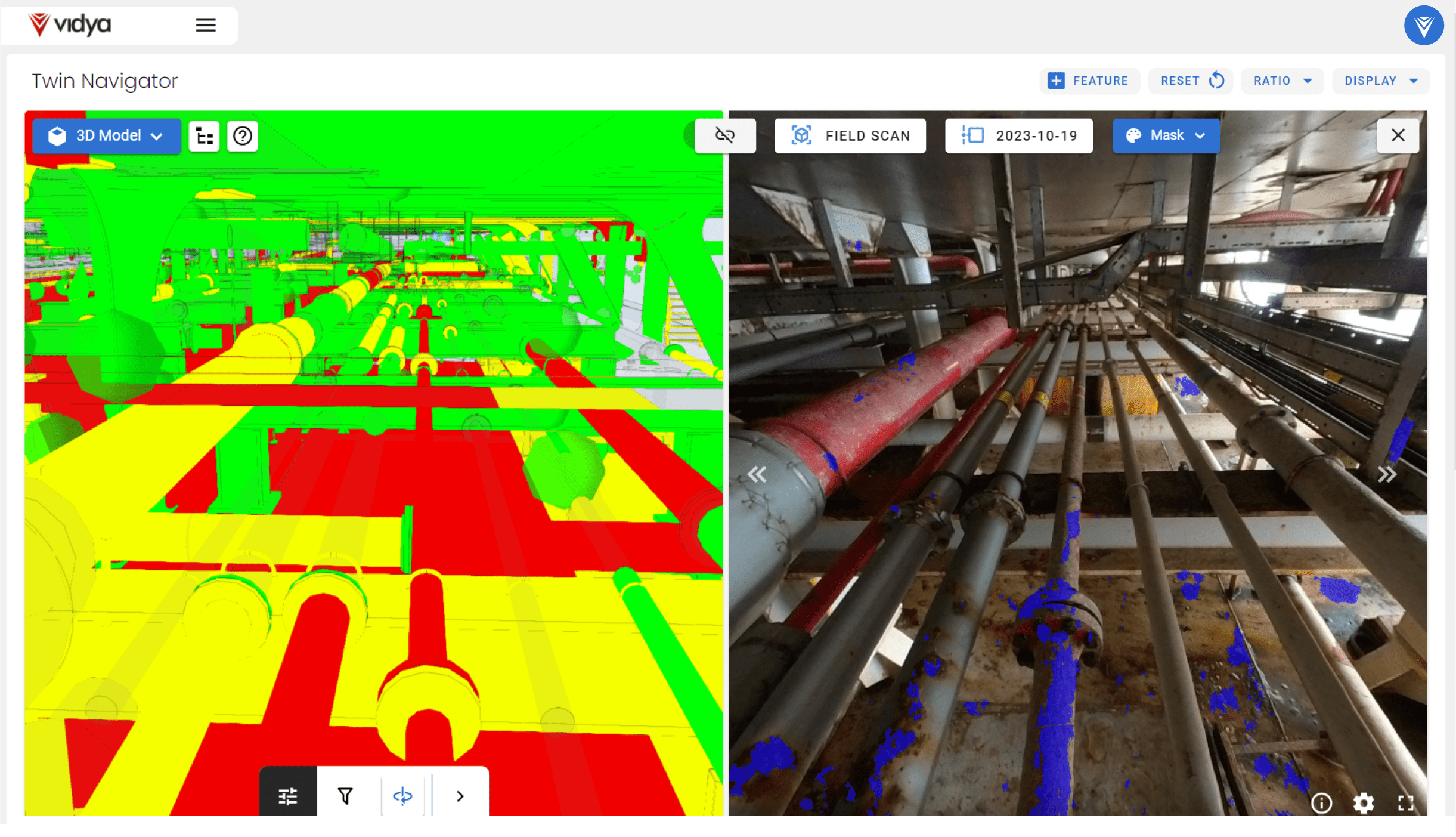

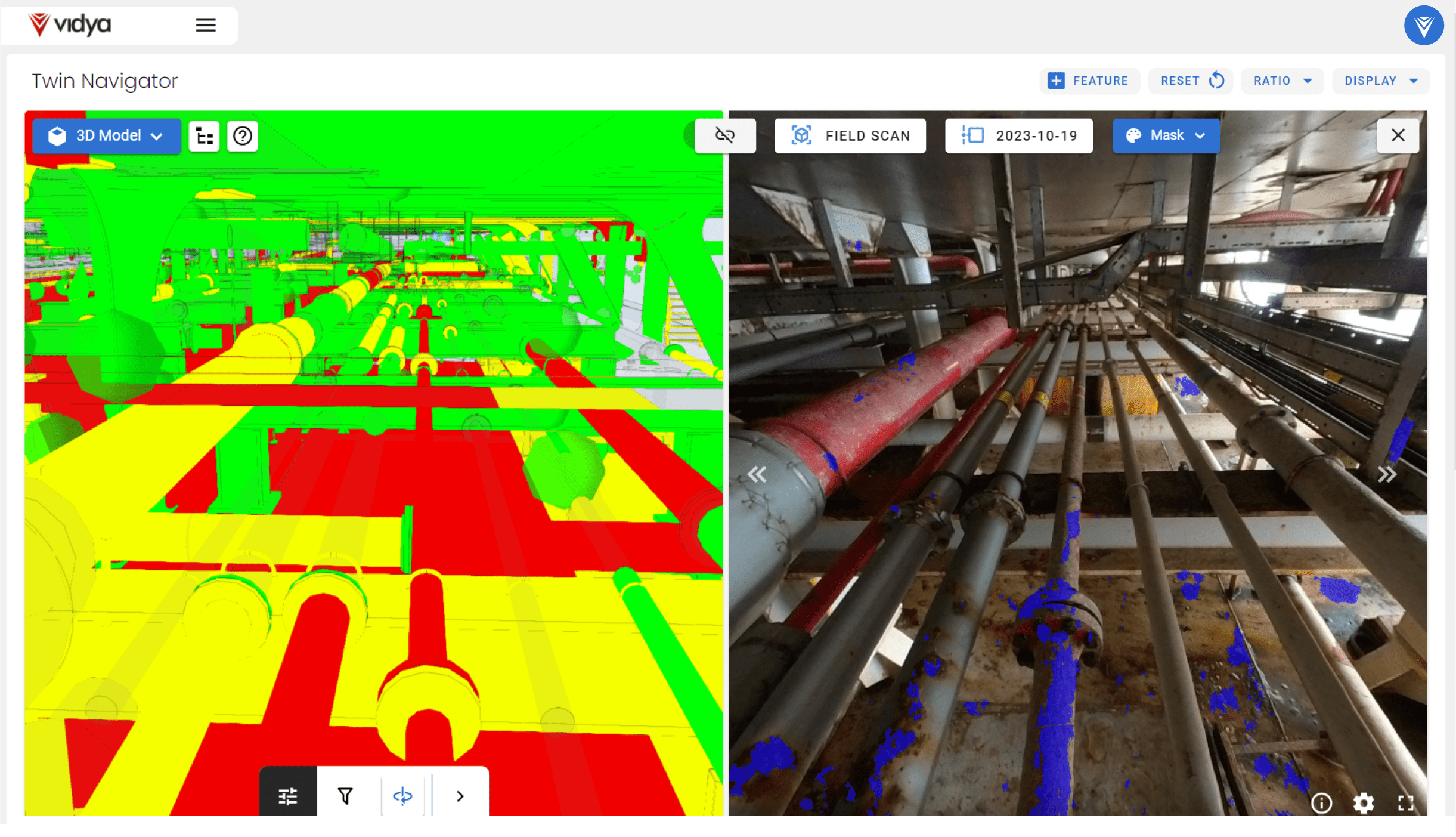

Our Digital Fabric Integrity application utilizes a unique combination of advanced technologies to streamline the inspection process. Image collection of the facility begins with the Reality Capture phase, requiring a minimal time of man-hours for field exposure. For instance, to cover the whole topside and maindeck of an FPSO (Floating Production Storage and Offloading), it takes 10 days. These captured images are then processed by our Machine Vision model, generating a comprehensive corrosion assessment along with detailed integrity notes delivered to your CMMS. This process empowers informed and precise maintenance planning.

For other assets, the Reality Capture phase can take:

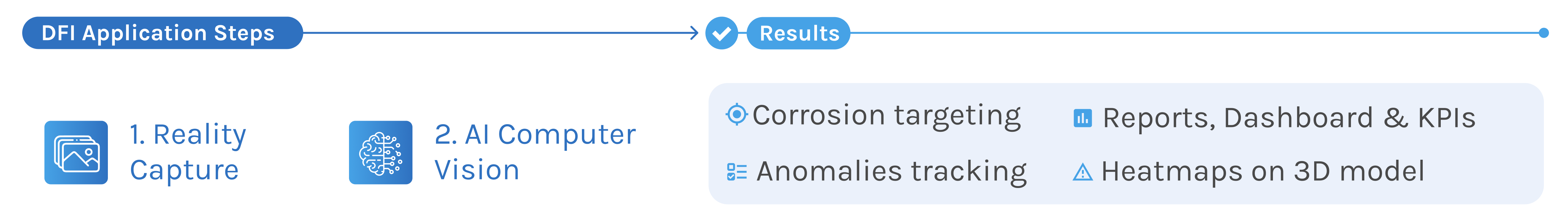

Oil Rig

to cover over 100 m²

Mining Equipment

[Stack reclaimer, conveyor]

Average Refinery

How does the Digital Fabric Integrity work?

Our Digital Fabric Integrity application utilizes a unique combination of advanced technologies to streamline the inspection process. Image collection of the facility begins with the Reality Capture phase, requiring a minimal time of man-hours for field exposure. For instance, to cover the whole topside and maindeck of an FPSO (Floating Production Storage and Offloading), it takes 10 days. These captured images are then processed by our Machine Vision model, generating a comprehensive corrosion assessment along with detailed integrity notes delivered to your CMMS. This process empowers informed and precise maintenance planning.

For other assets, the Reality Capture phase can take:

to cover over 100 m²

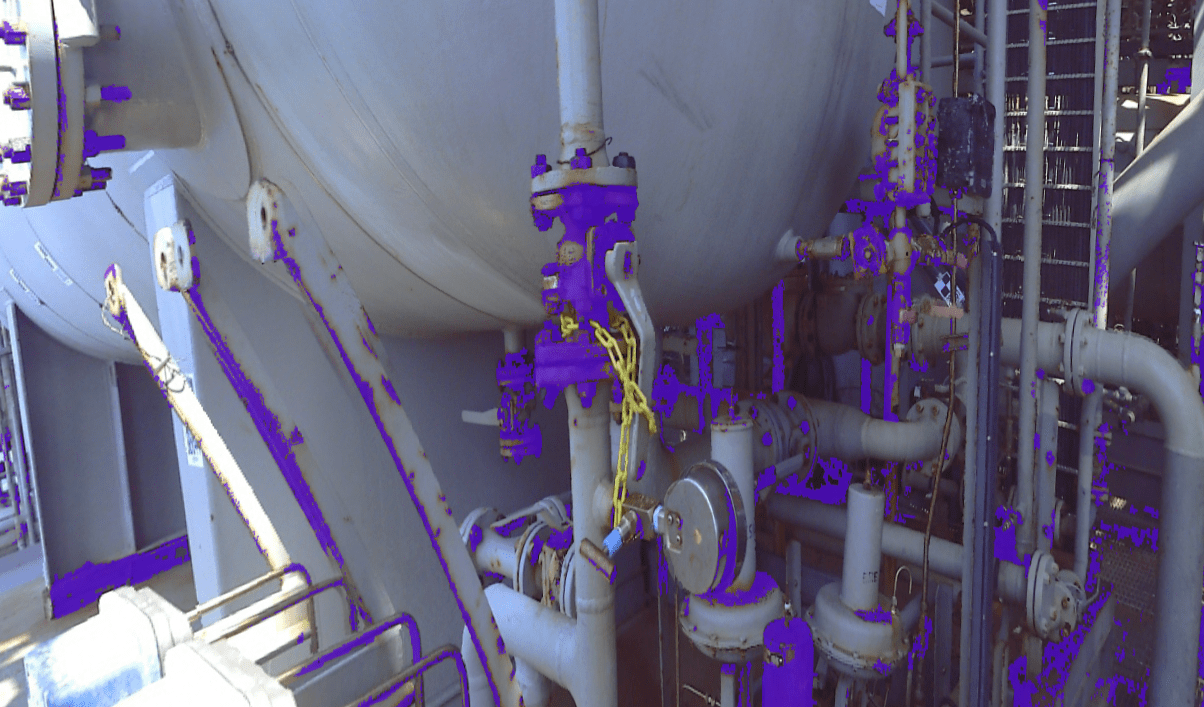

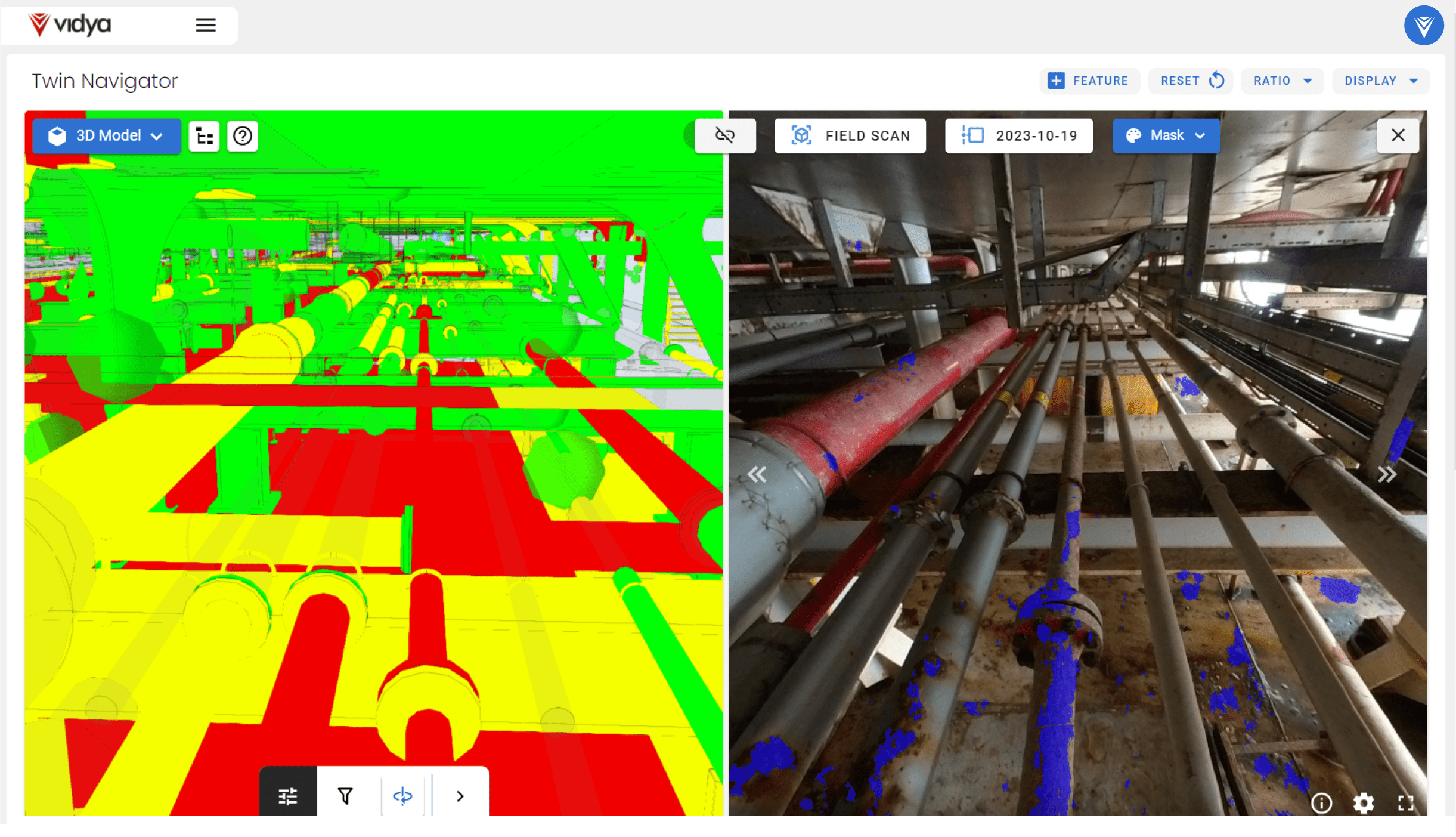

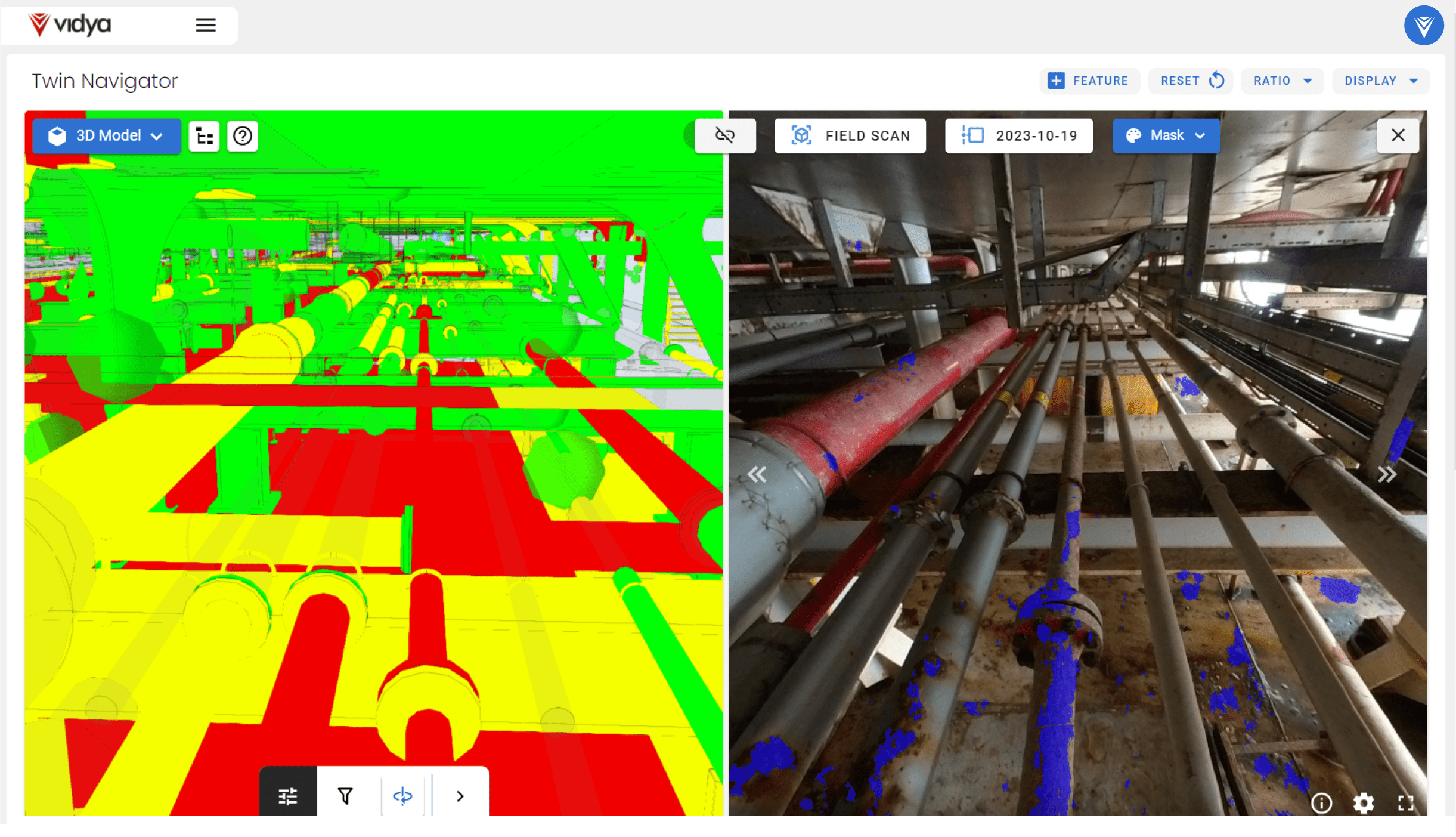

Reality Capture: Faster, Safer Inspections

AI Post-Processing: Clearer View, Actionable Insights

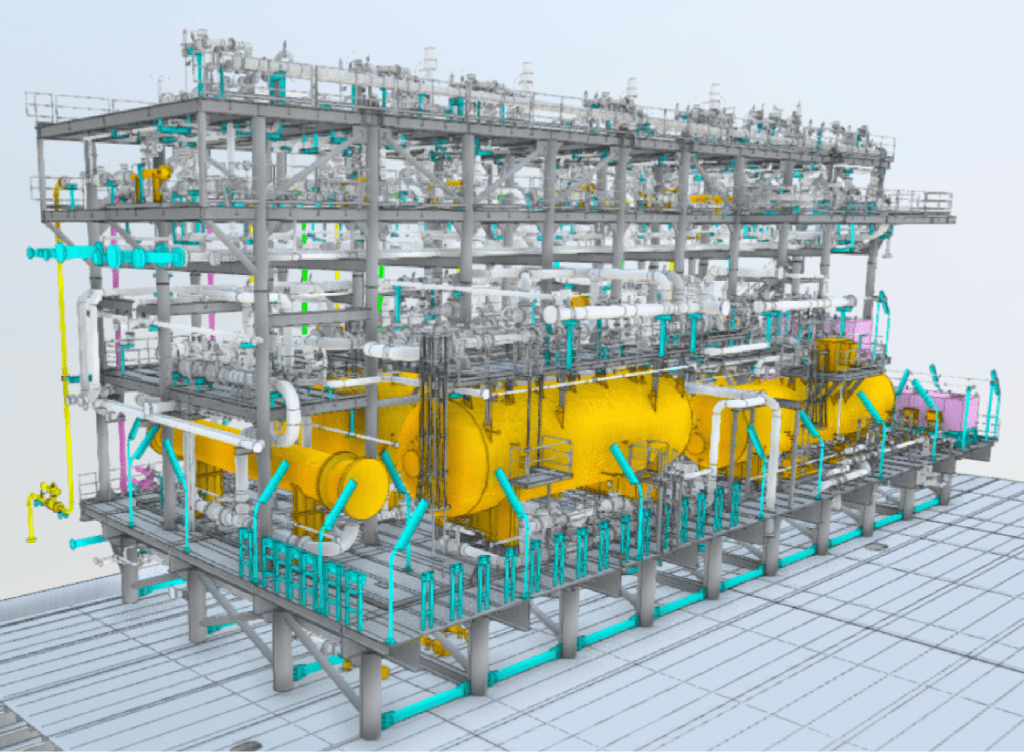

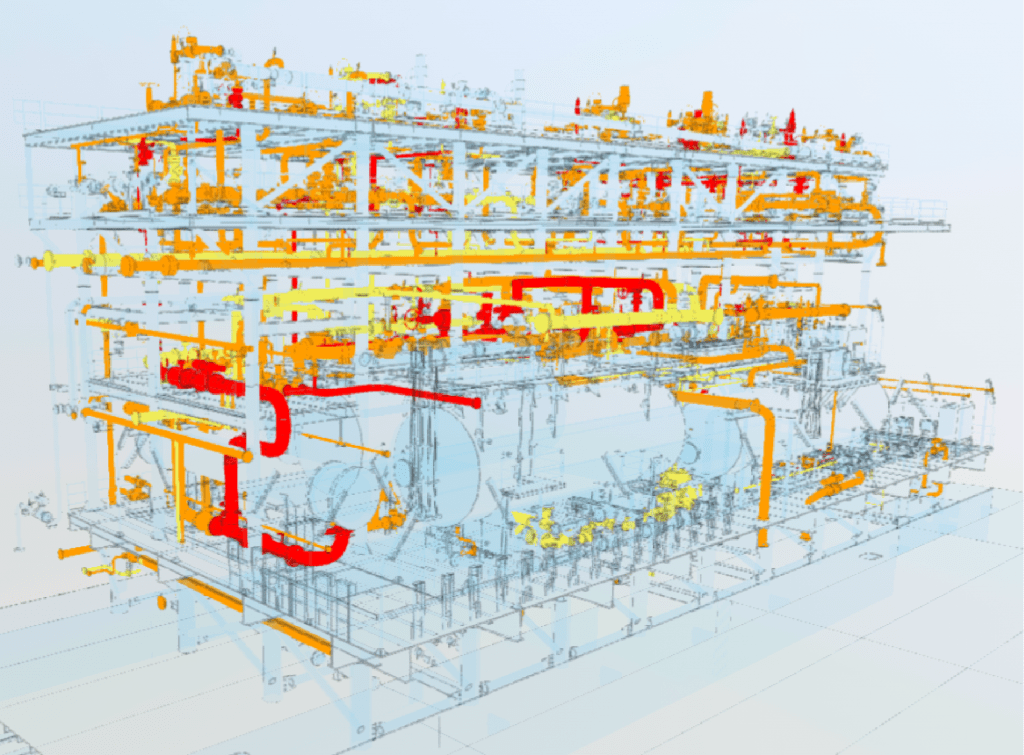

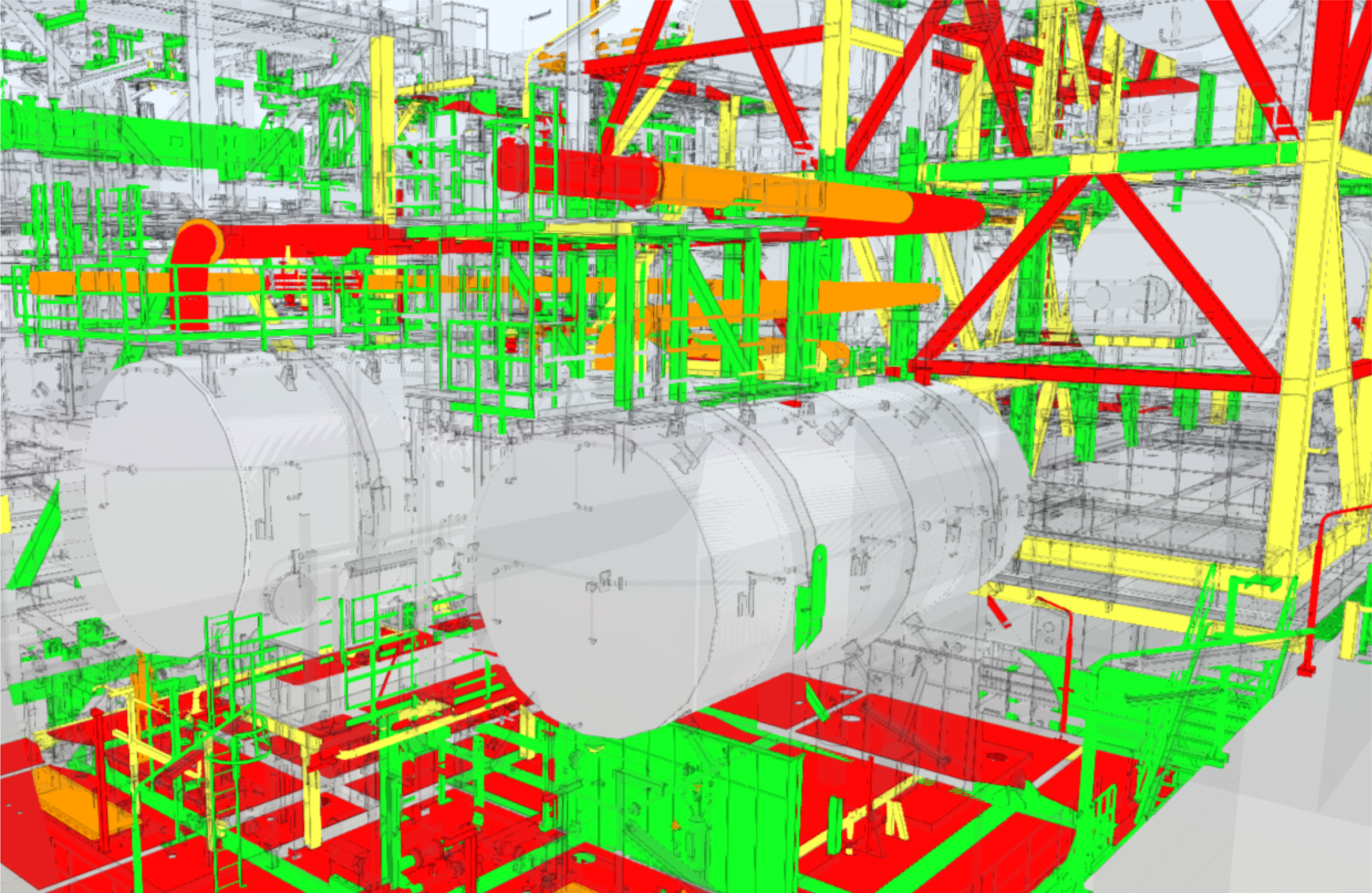

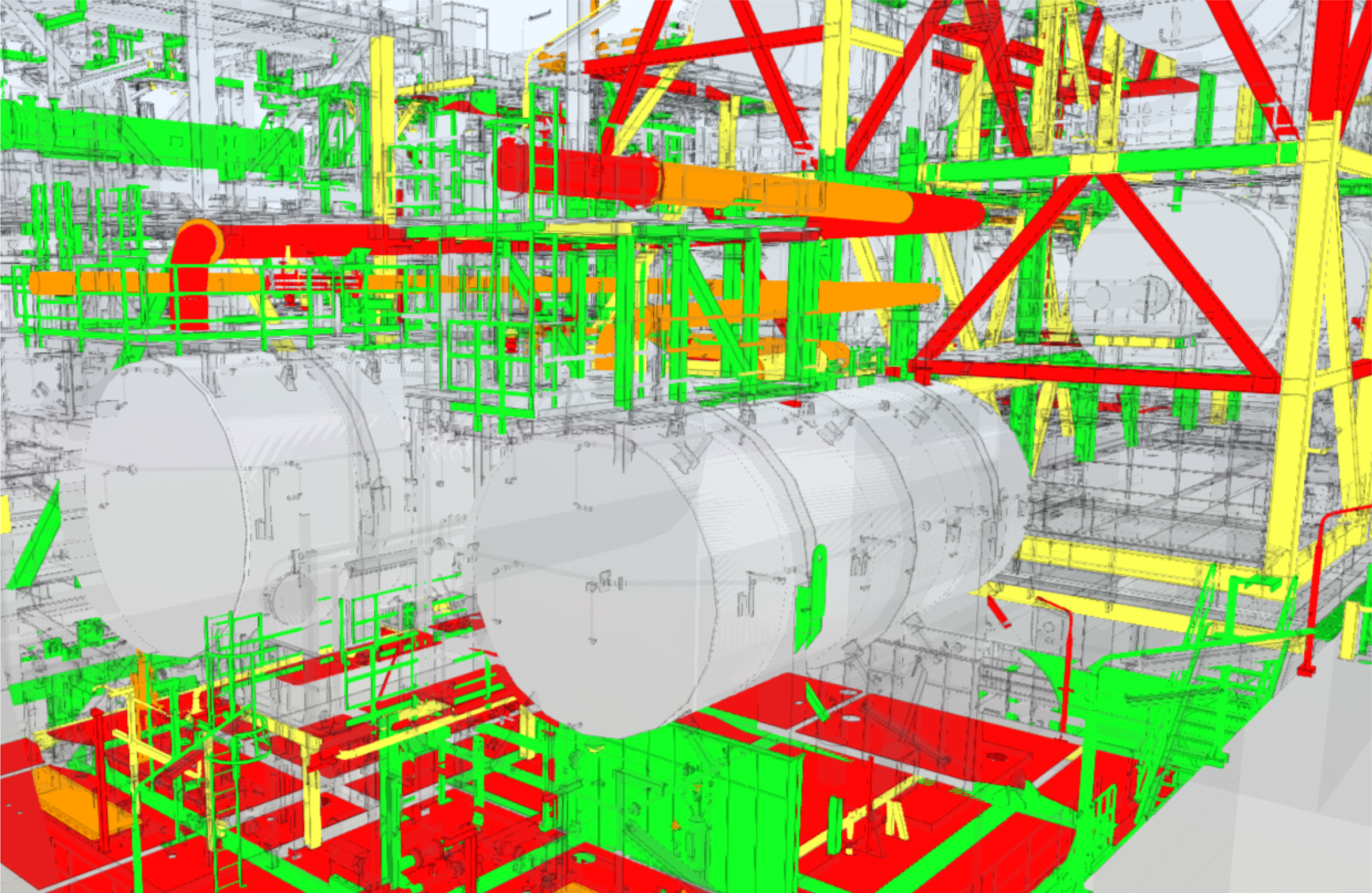

Systematic Risk Ranking: Heatmap Visualization

Corrosion may be inevitable

but its implications aren’t

but its implications aren’t

An effective corrosion assessment doesn’t try to avoid the natural process; it aims to control its impact. If left unmanaged, corrosion drives up maintenance costs, increases downtime, and creates safety risks. With Vidya’s Digital Fabric Integrity, industries gain complete visibility of corrosion progression, ensuring that anomalies are not only detected but also:

Impact generated

per year/campaign on FPSO

Value generated in only

Cycle time reduced from 150 days to under

Reduction in field inspection man-hours by

Why manage Fabric Integrity with Vidya

Tie Integrity decisions to Maintenance work with our Digital Fabric Maintenance Add-on

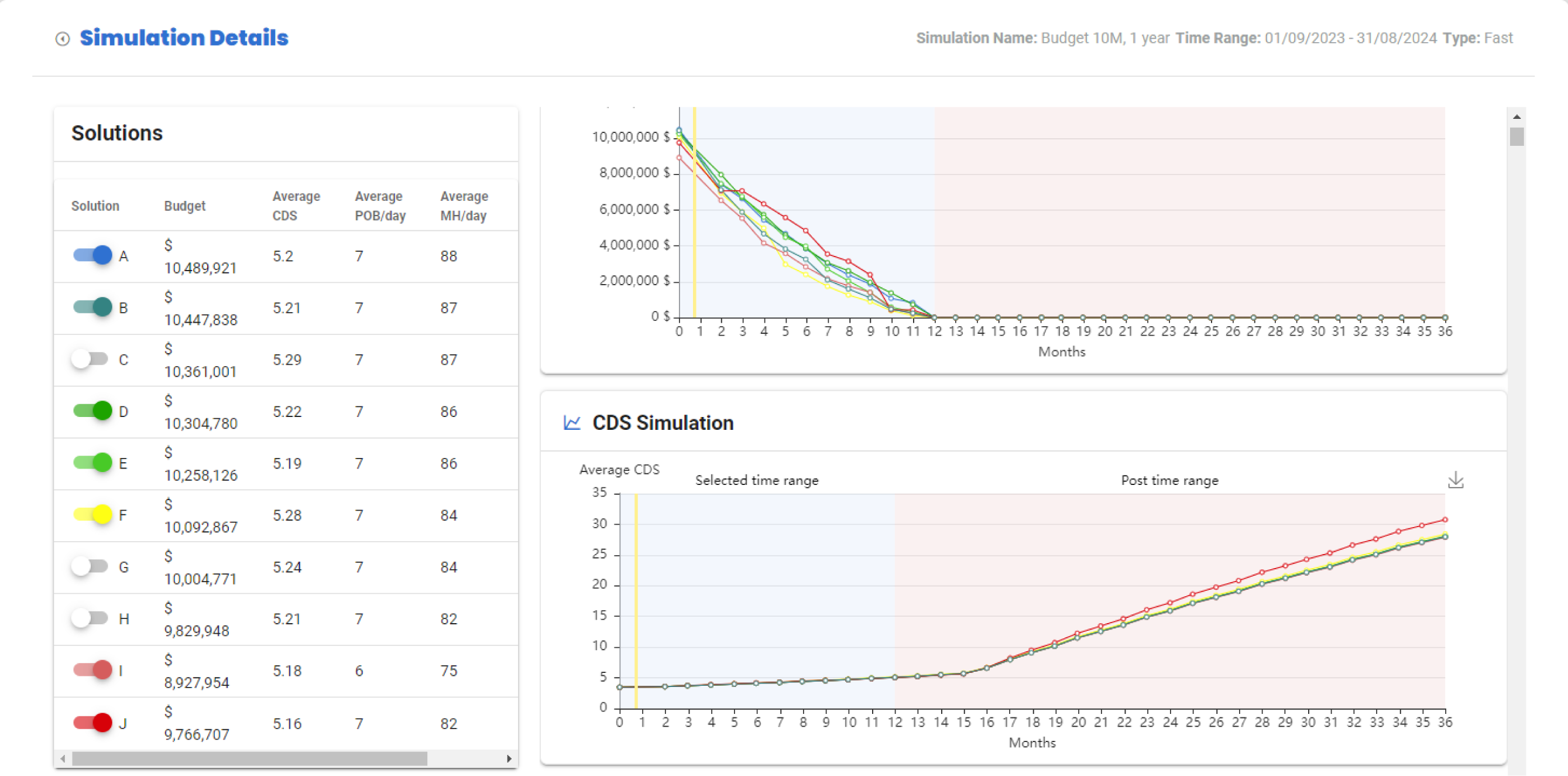

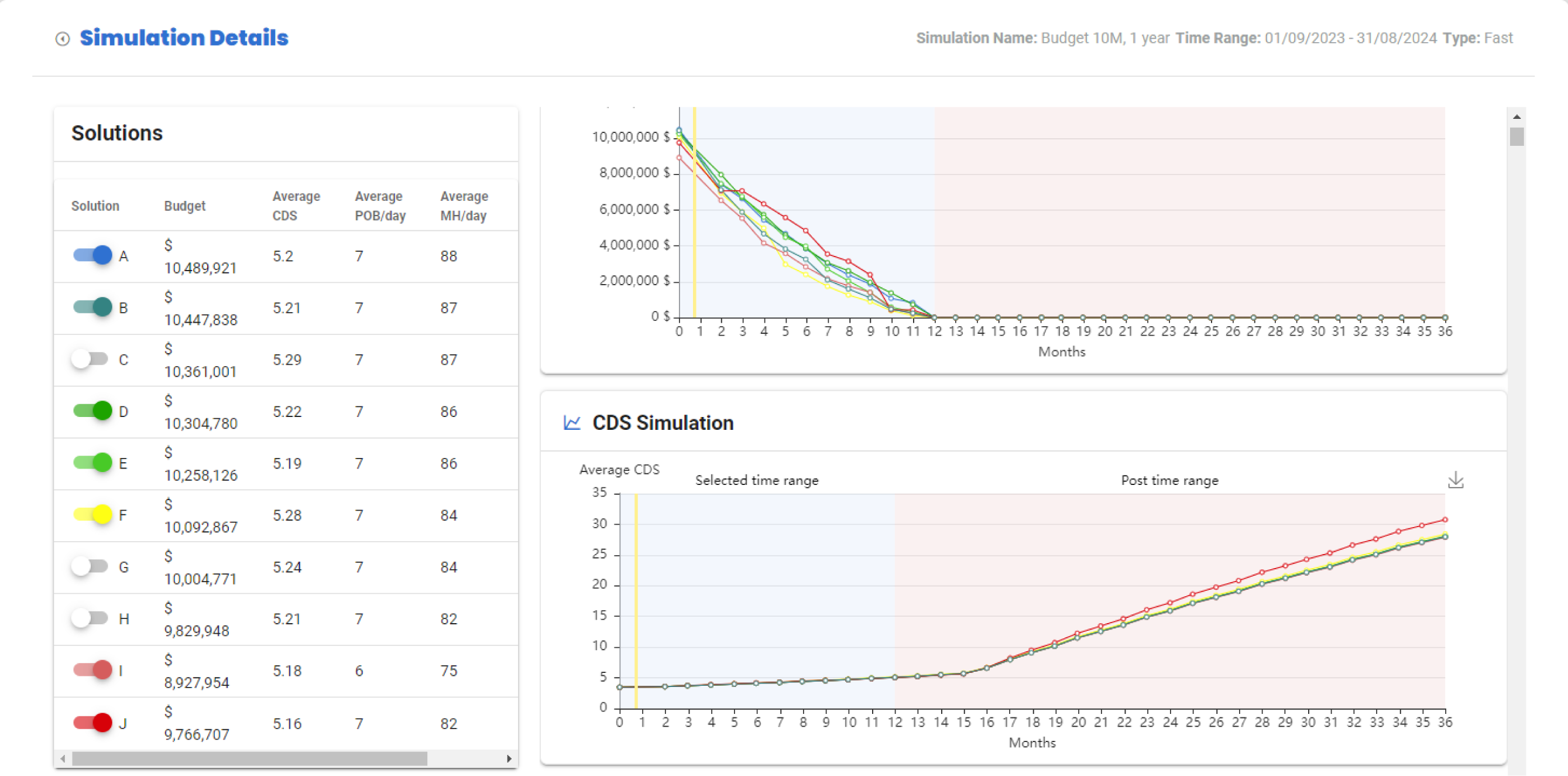

Connect Digital Fabric Integrity with our Digital Fabric Maintenance Application to close the loop between inspection insights and field execution. With the AI Budget Forecaster, you can allocate budgets, simulate corrosion degradation scenarios, and define the optimal maintenance campaign plan. From there, seamlessly plan and execute workpacks through the Digital Twin and Mobile Application, while tracking field efficiency.

Benefits overview

per year/campaign on FPSO

Days spent onboard for field data acquisition

Average POB reduction per FPSO

Reduction in rope access

Why manage Fabric Integrity with Vidya

Tie Integrity decisions to Maintenance work with our Digital Fabric Maintenance Add-on

Connect Digital Fabric Integrity with our Digital Fabric Maintenance Application to close the loop between inspection insights and field execution. With the AI Budget Forecaster, you can allocate budgets, simulate corrosion degradation scenarios, and define the optimal maintenance campaign plan. From there, seamlessly plan and execute workpacks through the Digital Twin and Mobile Application, while tracking field efficiency.

Internationally awarded solution

Trusted by researchers worldwide, this solution has been featured at +16 technical conferences

This solution was awarded by SPE (Society of Petroleum Engineers) in 22ATCE in Houston, and finalist for the 2023 MP Corrosion Innovation of the year award, by AMPP.

See Digital Fabric Integrity in Action.

Schedule a Demo & Experience the benefits. Contact us to learn how this solution fits your operation.

Beyond a digital solution, we help you to operate with ease. By scheduling a meeting, we will:

- Understand your challenges: We’ll listen closely to your top concerns around corrosion assessment and the current methods you’re using.

- Showcase our Digital Fabric Integrity application: : Discover how our technology streamlines corrosion assessment and processing, saving you valuable time and resources.

- Demonstrate real-world results: See firsthand the impact we’ve achieved for similar companies in reducing corrosion issues.

- Craft a tailored plan: We’ll work together to identify how our solution can specifically improve your corrosion management and monitoring processes.

- Propose a pilot: Lets target a specific area of your operation to address fabric integrity challenges. Experience the results and scale up for total transformation.

Send us an e-mail directly, if you prefer