AI-Driven Solutions for Hull Integrity Management

Inadequate hull or tank integrity management activities can result in unplanned vessel repairs, oil leaks, penalties, and in the worst cases, major accidents due to structural failures. Vidya employs AI-driven solutions which specifically target the external hull and tank integrity to guarantee a safe, reliable and sustainable FPSO operation.

AI-Driven Solutions for Hull Integrity Management

Inadequate hull or tank integrity management activities can result in unplanned vessel repairs, oil leaks, penalties, and in the worst cases, major accidents due to structural failures. Vidya employs AI-driven solutions which specifically target the external hull and tank integrity to guarantee a safe, reliable and sustainable FPSO operation.

Our company is trusted by:

Our company is trusted by:

Vidya technology External Hull and Tank Applications

Engineers are responsible for defining inspection strategies to support maintenance actions, which involves the manual analysis and interpretation of extensive technical reports, often being a time-consuming process. Through Vidya’s AI-Driven solutions, it’s possible to transform hull images and tank historical data into integrity outputs and engineering support.

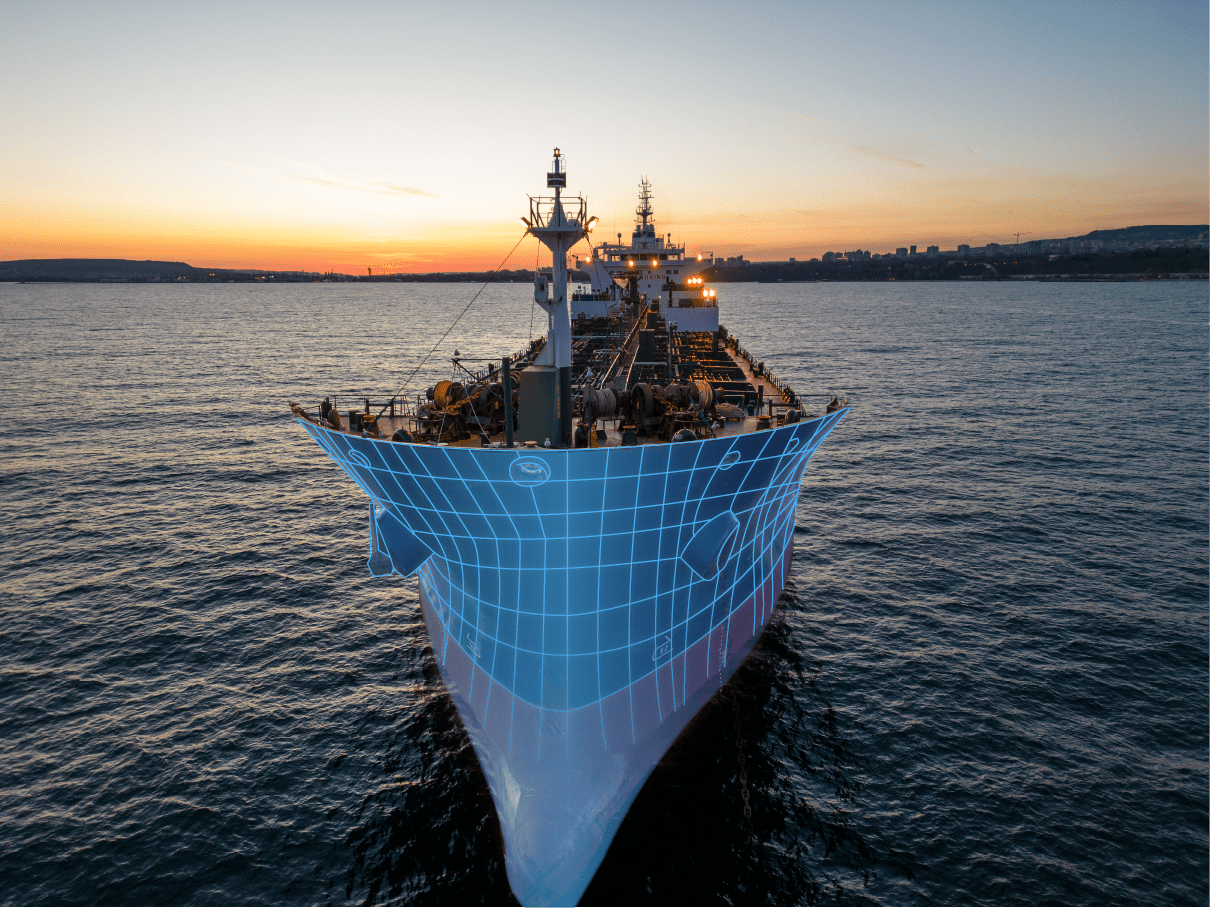

Naval Digital Tracking

The solution processes and visually contextualizes hull historical integrity data, such as thickness measurement and temporary repair history in an AI-Driven 3D environment.

Therefore, delivering the necessary outputs to support naval engineering and structural integrity teams on engineering analysis, lifespan or class society evaluations.

Engineering partner:

Naval Digital Tracking

The solution processes and visually contextualizes hull historical integrity data, such as thickness measurement and temporary repair history in an AI-Driven 3D environment.

Therefore, delivering the necessary outputs to support naval engineering and structural integrity teams on engineering analysis, lifespan or class society evaluations.

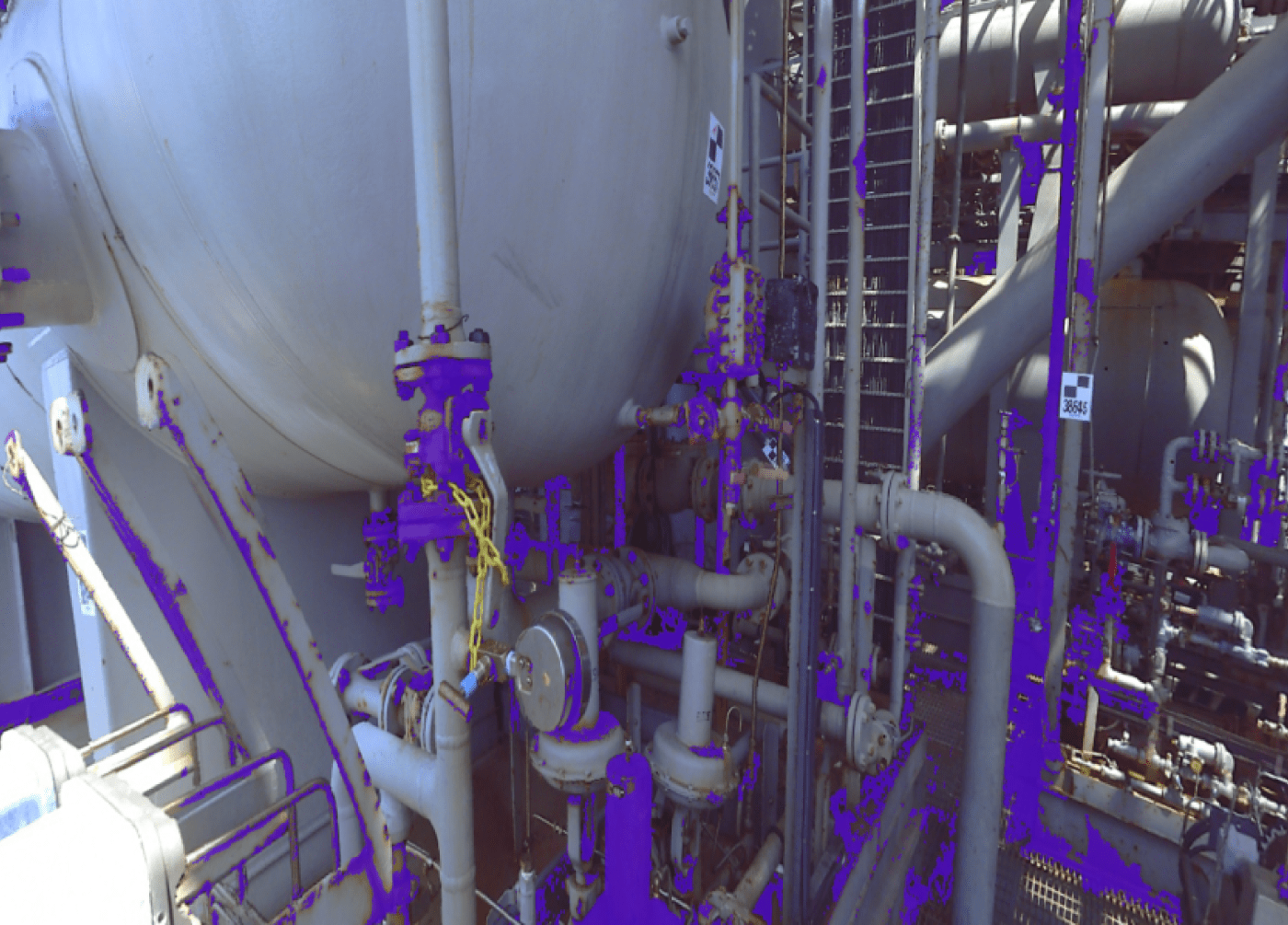

The solution combines reality capture with Artificial Intelligence to view, locate, classify and quantify potential discontinuities, pitting and critical corrosion points.

Therefore, reducing people on board and risk exposure for hull inspection, delivering precise anomalies targeting and classification to plan maintenance actions.

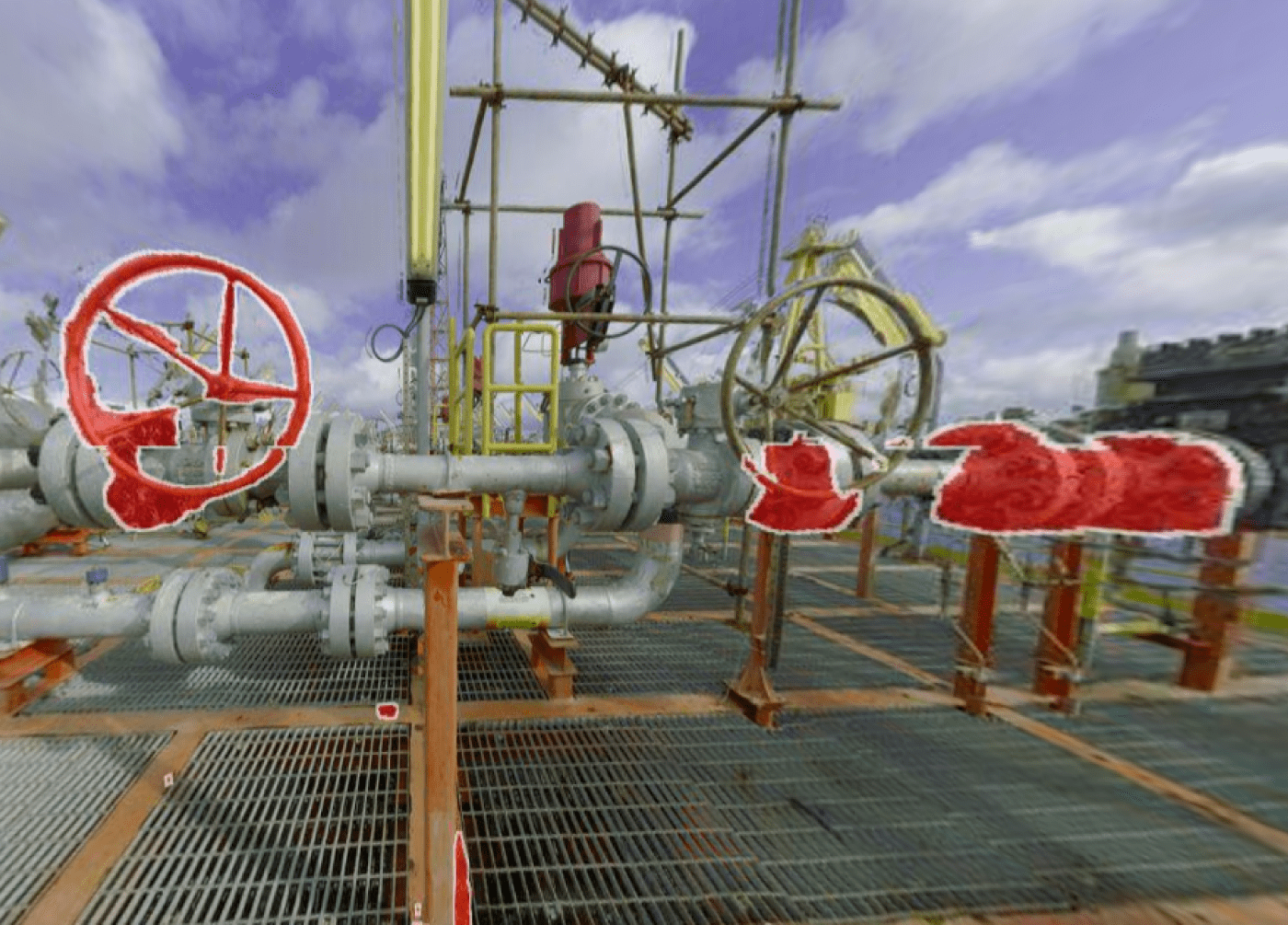

Digital Hull Tracking

AI Anomaly detection

The solution combines reality capture with Artificial Intelligence to view, locate, classify and quantify potential discontinuities, pitting and critical corrosion points.

Therefore, reducing people on board and risk exposure for hull inspection, delivering precise anomalies targeting and classification to plan maintenance actions.