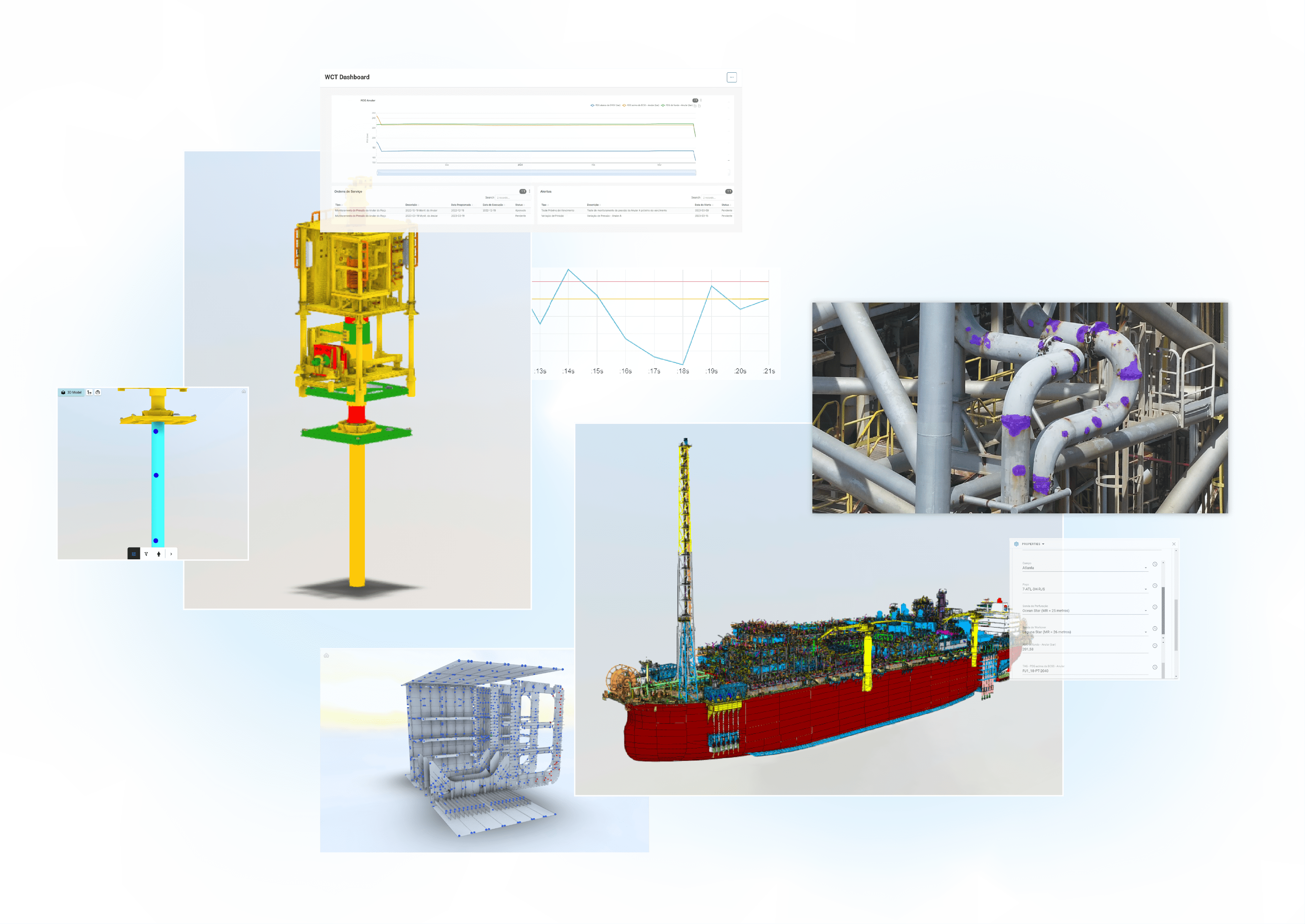

Upstream Asset Integrity Management, powered by AI:

Move beyond manual data analysis, people in risky areas, and unpredictable maintenance costs, and unlock the hidden potential of your inspection data. Vidya’s AI platform can predict equipment failures, optimize maintenance schedules, and maximize uptime across your upstream operations generating ROI over 450%.

Our company is trusted by:

Our company is trusted by:

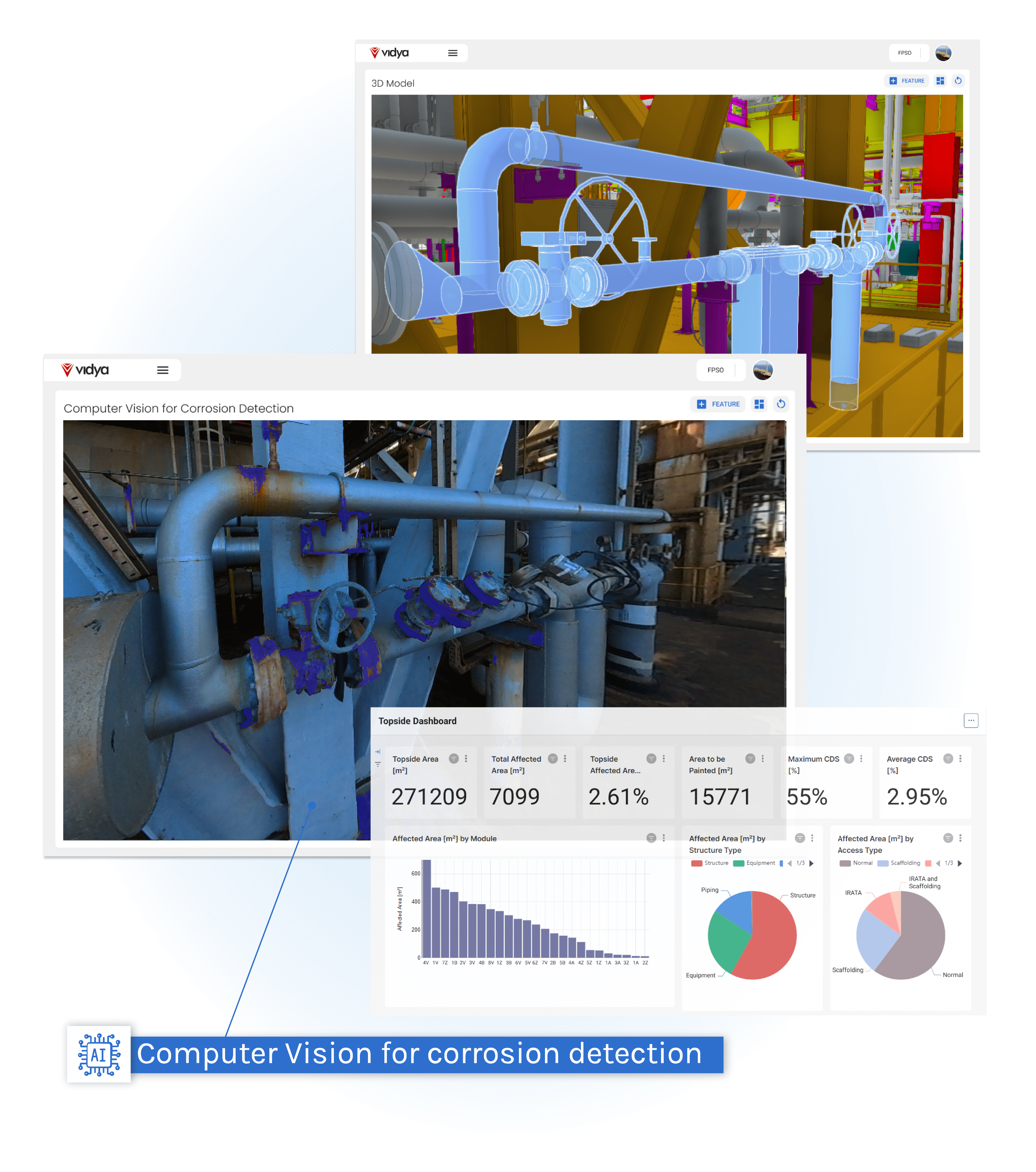

Digital Fabric Maintenance

Target Assets: Offshore Units, FPSOs, refineries

The Digital Fabric Maintenance (DFM) application comes as a solution to the broad problem of corrosion management within and is the ideal application for streamlining corrosion assessment with reduced PoB in highly corrosive environments.

From inspection to maintenance, DFM is enabling automated corrosion monitoring with the support of AI-driven corrosion identification and classification.

Digital Fabric Maintenance

Target Assets: Offshore Units, FPSOs, refineries

The Digital Fabric Maintenance (DFM) application comes as a solution to the broad problem of corrosion management within and is the ideal application for streamlining corrosion assessment with reduced PoB in highly corrosive environments.

From inspection to maintenance, DFM is enabling automated corrosion monitoring with the support of AI-driven corrosion identification and classification.

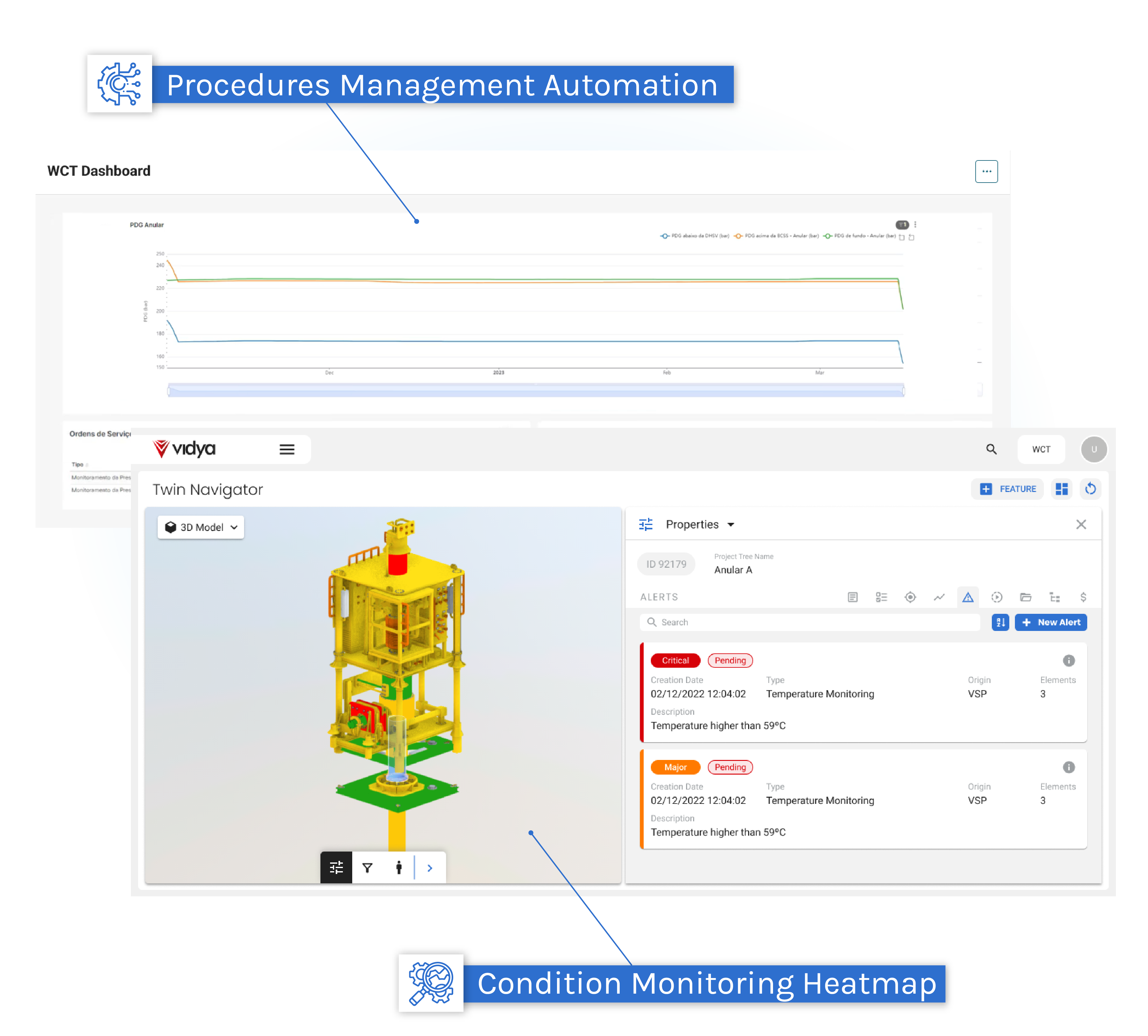

Digital Well Integrity

Target Assets: Blowout preventers, Subsea Christmas Tree, Risers, Manifold, SDU, Flow Lines and others

The solution is designed to streamline well integrity management, centralizing and contextualizing operational data and ultimately represent subsea anomalies and deviations through dynamic visual representation.

Ensure precise risk management, maintenance support, and timely alerts tailored to intervention needs. This approach allows quicker access to critical information and maintenance support based on accurate data.

Digital Well Integrity

Target Assets: Blowout preventers, Subsea Christmas Tree, Risers, Manifold, SDU, Flow Lines and others

The solution is designed to streamline well integrity management, centralizing and contextualizing operational data and ultimately represent subsea anomalies and deviations through dynamic visual representation.

Ensure precise risk management, maintenance support, and timely alerts tailored to intervention needs. This approach allows quicker access to critical information and maintenance support based on accurate data.

Digital Hull Tracking

Target Assets: FPSO – External Hull

The solution combines reality capture with Artificial Intelligence to view, locate, classify and quantify potential discontinuities, pitting and critical corrosion points.

Therefore, reducing people on board and risk exposure for hull inspection, delivering precise anomalies targeting and classification to plan maintenance actions.

Digital Hull Tracking

Target Assets: FPSO – External Hull

The solution combines reality capture with Artificial Intelligence to view, locate, classify and quantify potential discontinuities, pitting and critical corrosion points.

Therefore, reducing people on board and risk exposure for hull inspection, delivering precise anomalies targeting and classification to plan maintenance actions.

Engineering partner:

Naval Digital Tracking

Target Assets: FPSO – Tank

The solution processes and visually contextualizes hull historical integrity data, such as thickness measurement and temporary repair history in an AI-Driven 3D environment.

Therefore, delivering the necessary outputs to support naval engineering and structural integrity teams on engineering analysis, lifespan or class society evaluations.

Engineering partner:

Naval Digital Tracking

Target Assets: FPSO – Tank

The solution processes and visually contextualizes hull historical integrity data, such as thickness measurement and temporary repair history in an AI-Driven 3D environment.

Therefore, delivering the necessary outputs to support naval engineering and structural integrity teams on engineering analysis, lifespan or class society evaluations.

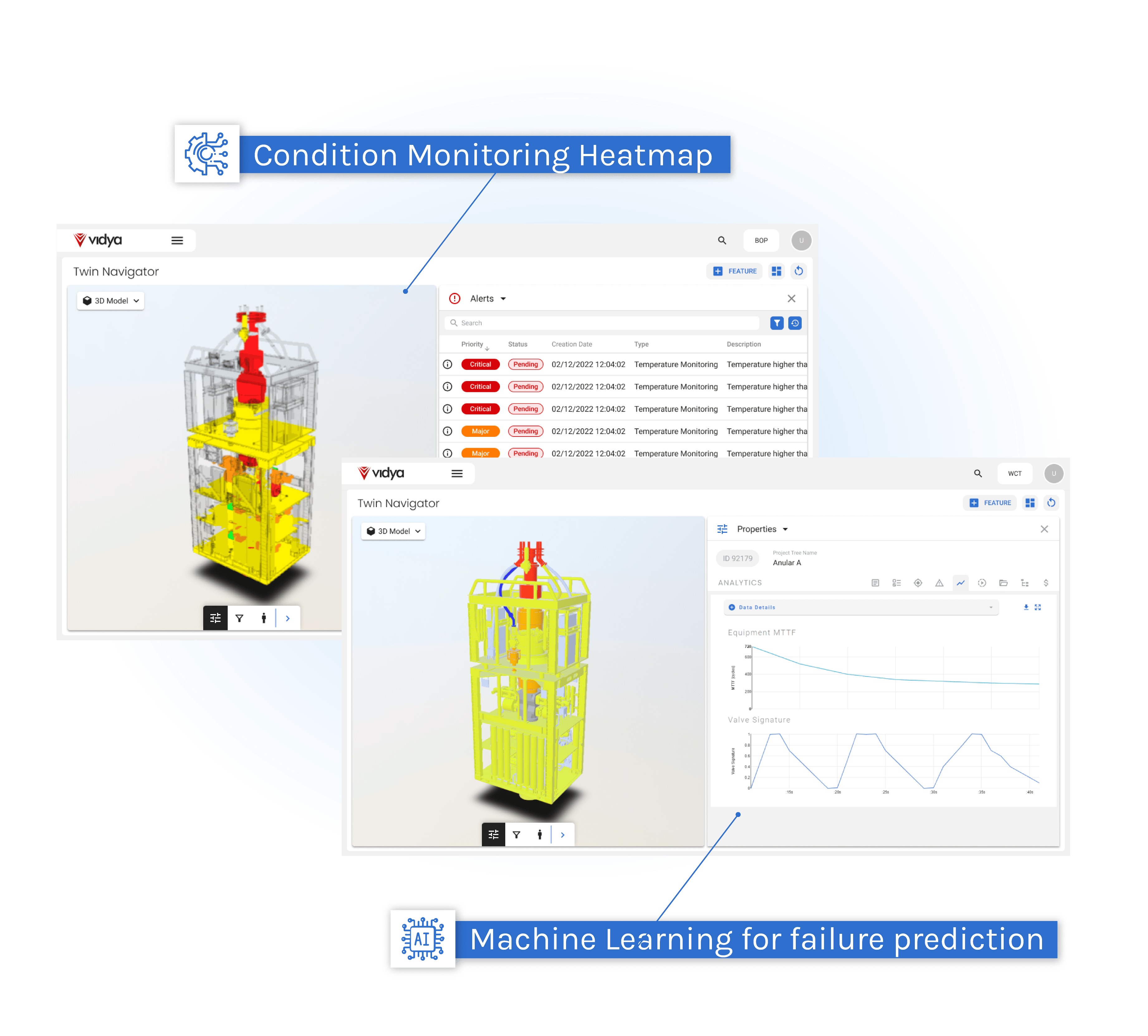

Digital Equipment Performance

Target Assets: BOP (Blowout Preventer), Iron Roughneck, Subsea Christmas Tree, and other critical equipment

The solution enables monitoring of critical equipment performance and integration of large volumes of data through data engineering and artificial intelligence. This application enables faster mapping, analyzing, treating and correlating of equipment data.

Therefore resulting in precise predictive analysis, reduced time between failures, and accurate maintenance planning connected to ERPs and CMMSs.

Digital Equipment Performance

Target Assets: BOP (Blowout Preventer), Iron Roughneck, Subsea Christmas Tree, and other critical equipment

The solution enables monitoring of critical equipment performance and integration of large volumes of data through data engineering and artificial intelligence. This application enables faster mapping, analyzing, treating and correlating of equipment data.

Therefore resulting in precise predictive analysis, reduced time between failures, and accurate maintenance planning connected to ERPs and CMMSs.

Innovation never stops

We’re constantly pushing the boundaries of what’s possible with AI, developing new solutions that address the evolving needs of the upstream industry.