IoT (Internet of Things) has become, over the last few years, one of the essential technologies for the industry. Every day the interconnectivity of devices becomes greater, the idea of having cities interconnected through billions of devices is already something that permeates reality. Access to cheaper processing networks, microchips, and sensors has made the IoT technology accessible and made its popularity arise.

If you want to know more about the importance of IoT, see our ebook understanding IoT in 5 steps

The industry has been gradually adapting to this new scenario and constantly creating new solutions and new functions for the use of IoT, in this blog we will show you how to take advantage of the Internet of Things and how it can add value to industrial operations.

The incorporation of elements with the use of sensors in the industries has as primary objective to create what we call M2M communication (Machine to Machine), in this way important data will be connected, transmitted, and collected by the machines, creating then a data network.

This data exchange makes the communication process between different elements much faster and more assertive. These data make it possible to get a view of a whole scenario, which can later be used for the analysis of loss of productive capacity and efficiency within industrial plants.

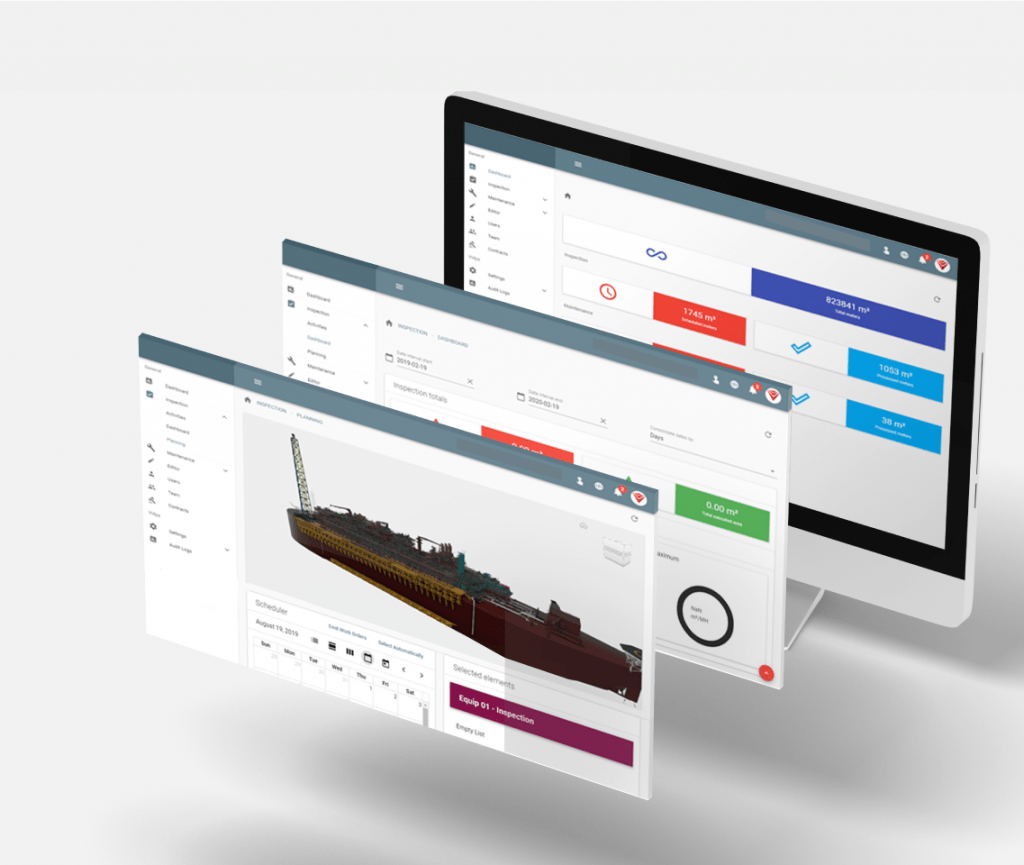

The user has access to this data through specific interfaces that can be accessed remotely via smartphones or tablets. The management and analysis of this information culminates in process automation, known worldwide as “Smart Manufacturing”.

The intercommunication of these various elements within an industrial facility enables the management of industrial assets in an optimized way.

With a well-fed data network, managers can access information that will support the management of specific operations. Decision making is then assisted, as machines within different systems and different functions start to communicate with each other.

The resolution of eventual problems becomes faster, and optimization points can be found more easily. You can even have minimal readings of parts wear and eventual failures within the process.

But what are the opportunities that the Internet of Things can bring to a company?

Well, with the automated management of several assets, the workforce can be moved to other areas of production, being able to carry out other activities that involve a higher degree of complexity. The travel time of employees and operations is also optimized, thanks to automation, the execution time, processing and information sharing happen in seconds.

Maintenance resource management is another benefit that industries should look favorably on. Software specialized in asset management that is powered by the IoT data network can detect wear and tear and thus the risk of having an entire extraction line interrupted for a long time becomes minimal.

For the Oil and Gas, Pulp and Paper and Petrochemical industries, this functionality becomes even more interesting, considering that these plants involve a greater degree of complexity due to the high wear and corrosion of their systems.

And what are the scenarios for the implementation of IoT by industries?

According to a study by Forbes magazine, industrial products are the ones that lead the use of IoT in their facilities with 45%. The magazine also mentions an additional 22% in companies that are scheduled to implement IoT over the next 12 months.

The same study also reveals that the forecast is that the IoT market in industries will exceed the value of 123 billion dollars with an annual growth rate of 7.3% in 2020.

Now that you know how the use of IoT drives the results of the industry, click here and read our blog where I explain how IoT is capable of revolutionizing the industry.