The technologies driven by industry 4.0 and the digital transformation have been helping many industries to adapt to a new model of operation guided by digitalization, which is establishing itself in the market.

Among these new technologies, IoT (Internet of Things) is one that has been attracting attention due to its various applications.

The importance of this technology for the industry and its functionalities applied to operations and processes are already well known by a large part of the sector. Many companies tend to adapt to this new scenario so that they can make the best use of the benefits generated by the application of IoT sensors.

Read: The secret for a better performanc of IoT sensors in the field

IoT and Tools for Industries

Despite being an amazing technology, IoT sensors have their potential enhanced when used in complementarity with other technologies, thus allowing a wider range of applicability. Among them, collaboration with:

Digital Twins: Sensors are used to collect information and feed the digital twin’s continuous data flow.

Artificial Intelligence: The data collected by the sensors can be processed through algorithms to identify patterns and predict scenarios

Cloud: With cloud systems, the data collected by the IoT sensors can be stored on decentralized platforms facilitating access and interpretation of the data.

Combining these technologies it is possible to generate value in multiple disciplines within the operations.

IoT sensors applied for greater safety within operations

Asset integrity management is the discipline in which the use of IoT technology directly contributes to the continuity of the operation, security for operators, and the automation of maintenance and inspection plans.

This integrity discipline can be improved in many ways, from collecting corrosion rates in a pipeline to software capable of managing an entire industrial plant.

Some of these tools are:

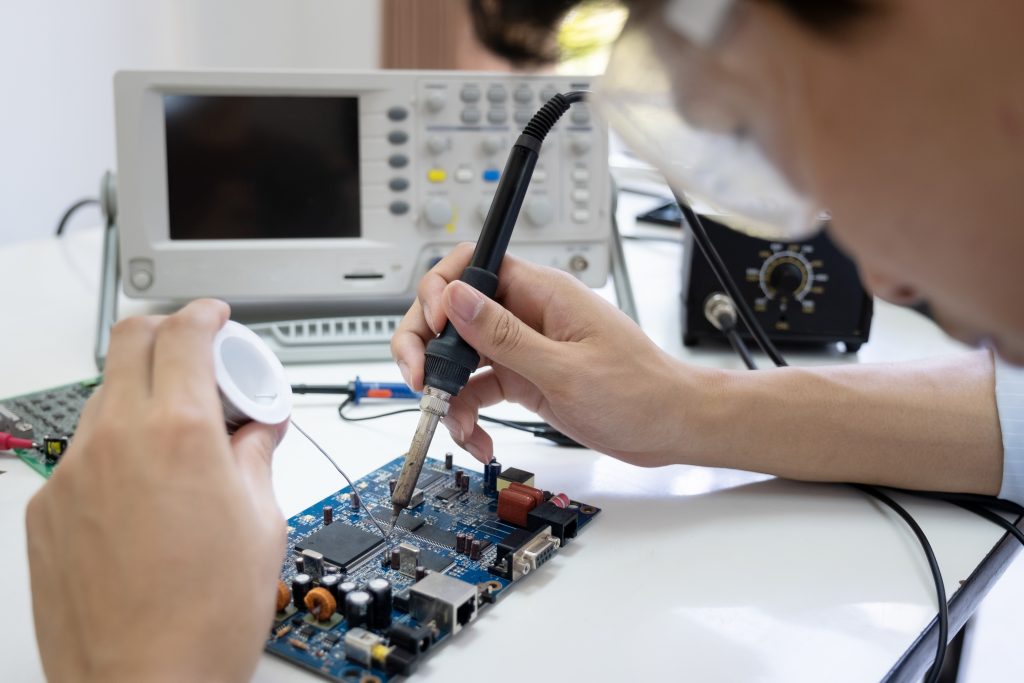

IOT Data Logger

The data logger is hardware for real-time data collection equipped with sensors that automatically extract and store electrical resistance measurements from corrosion probes in the data logger. This device is applied in conductive or non-conductive environments, such as chemicals, water, gas, and oil systems.

The Data Logger provides access to real-time data that is sent to a Cloud platform.

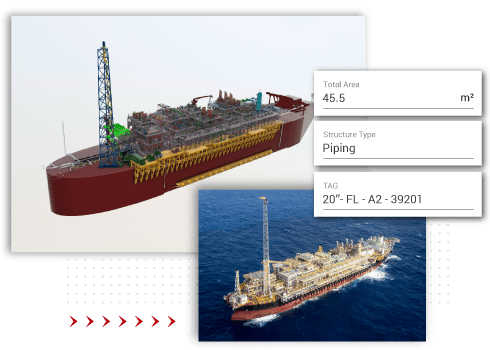

Vidya Digital Twin Software

Vidya Software is a platform used for asset integrity management that manages the automation of maintenance and inspection plans, based on information collected in the field. With the use of Digital Twin, IoT, and Artificial Intelligence, this platform allows an entire industrial plant to be replicated within its interface through 3D scanning, engineering models, sensors, data collected in the field through a mobile app, among other factors relevant to the operation.

All processes and data are directly linked to virtual representation. Therefore, it provides a constant flow of data and information, which serves to predict, simulate and generate knowledge for decision making.

Having this data in hand, within the software itself, it is possible to draw up maintenance and inspection plans, generating schedules and work orders for inspection.

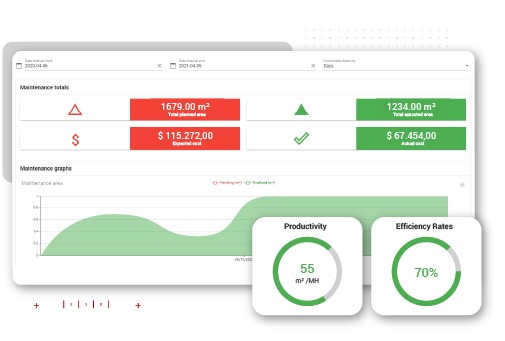

The software allows better management of resources and manpower, allowing the management of work orders through customizable BI dashboards that favor the visualization of the status of assets through images, tables, graphs, and widgets

These are just some of the features that these tools can perform. It is thanks to the DNA of innovation and resilience in the journey of digital transformation that today industries can be ahead of their time and generate more and more value to their operations with technologies that are increasingly smarter and aligned with their needs;