The application of new technologies in the most diverse industries has shown very positive results when it comes to greater control of the operation and improvement in results. In the case of steel industries, this scenario is intensified.

Located in harsh environments and operated in critical situations, the digitization of processes and improved data collection and analysis has allowed these industries to reduce unplanned downtime, improve worker safety, and cut operational costs. As the main protagonist of this digital transformation, there is the Digital Twin.

Here is a more detailed explanation of how Vidya’s application of this technology can benefit the Steel Industry operation:

3 Benefits of Digital Twin in Steel Industry

1. Unplanned downtime minimization

Dealing with unplanned downtime in Steel Industry equipment is quite complicated, as these machines operate in very critical environments, and it is not possible to perform these pauses at any time.

Our Digital Twin, through the constant exchange of information with the real environment, allows a better planning of stops for inspection and maintenance. This happens because it uses data collected from the operation to generate failure predictions and replace corrective maintenance methods, in which the problem is waited to happen in order to act on it, by predictive methods, correcting any inconsistency in the operation before it affects the production as a whole.

By expanding this type of action to all processes, it is possible to have a much more complete planning and control over the operation, in order to reorganize production if necessary, optimize the performance of workers in the field, and increase the useful life of equipment and its mean time between failure. This also allows achieving other benefits such as the reduction of on-site workers and overall cost reduction, which will be explained below.

2. Workers safety

The assertiveness of action provided by Digital Twin predictive maintenance also reduces the risks that field workers are submitted to. Besides minimizing accidents due to equipment malfunction, since the maintenance of these assets becomes more effective, the time spent on rework is also minimized.

In addition, the contextualization, integration, and processing of operation data in the technology allows the information analysis to be performed remotely, reducing the need for people in the field. Thus, the analog methods of risk analysis, failure and efficiency are replaced and workers no longer need to expose themselves unnecessarily to the criticalities of the Steel Industry operation, such as high temperatures.

3. Cost reduction

One of the final main benefits of this whole digitalization process based on the Digital Twin is the reduction of the industry’s OPEX.

All the consequences of increasing the time between equipment failures, predictively acting on operational problems, reducing rework, and maximizing process efficiency translate into lower component costs and total maintenance expenses.

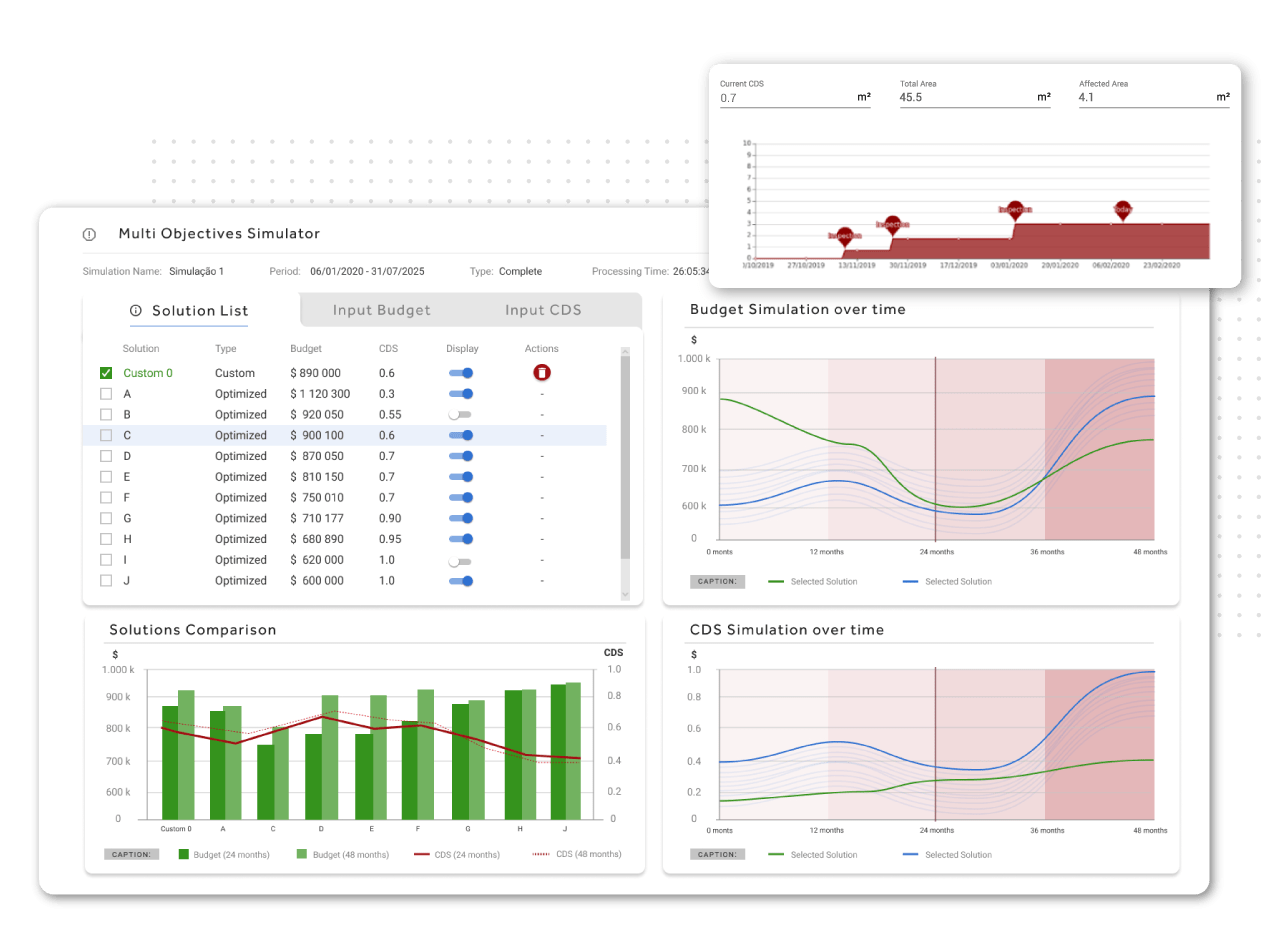

Vidya’s Digital Twin is also able to cross-reference historical efficiency data with expenses and budget information required for equipment maintenance, generating time graphs to indicate the most cost-effective time to perform maintenance on an asset.

Conclusion

The application of Digital Twin in the Steel Industries shows itself as one of the best opportunities from the perspective of transforming the current environment of these companies to a data-driven context.

The contextualization and processing of data provided by Vidya allows the reduction of unplanned downtime of the operation, while increasing workers’ safety and reducing plant operating costs.

However, Digital Twin’s applications go far beyond this and are able to adapt according to the difficulties presented in the operation. Want to know how this is possible? Download our one-page brochure below and learn even more about our solution!