Digital twin is a technology that has gained great prominence over the past few years for generating amazing results.

The technology emerges in the midst of a movement known as digital transformation, which has revolutionized the way companies relate to their customers, operate, and develop their products and services.

What is a Digital Twin?

Despite the big boom behind the digital twin the term was conceived in 2002 by Michael Grieves and has since been applied for different purposes.

But how could we define a digital twin? Well, the technology consists of a digital replica of the real world. This concept had already been explored in the book Mirror Worlds by German computer science professor David Gelernter in 1991. But it was not until 2002 that the technology with the real-world application was developed by NASA.

The digital twin mirrors everything from one piece of equipment to entire cities and human beings. For mirroring to take place a continuous flow of data must be established on both sides (digital and real)

Technologies that relate to the Digital Twin

As mentioned earlier, the digital twin is the output of the movement of intense change known as digital transformation. Several other technologies have also emerged in this revolution, many of which relate to the Digital Twin because of its interoperable potential, further increasing its range of applications. Among the technologies developed and strongly related to the Digital Twin are:

IoT (Internet of Things)

This technology is responsible for M2M (Machine to machine) communication. Through sensors, devices, equipment, and machines can be connected and exchange data with each other. Among the various possibilities generated by the use of IoT, are the communication between machines without interference from human actions.

Artificial Intelligence

Artificial intelligence is the science that groups several subfields of computer science with the goal of developing and improving intelligent computer systems to perform complex activities. Digital Twin aggregates AI by providing ways to perform complex tasks associated with intelligent beings.

Machine learning

Machine learning is one of the many branches of what we know today as artificial intelligence. This technique allows algorithms to learn and gain experience from processed data. Machine learning processes data by cross-referencing its information so that it can establish relationships, patterns, and predictions. The use of ML in conjunction with a digital twin provides the ability to predict and simulate future scenarios, one of the most attractive benefits of the technology.

Big Data

Big Data is another subgroup of Artificial Intelligence, responsible for storing and processing large amounts of data, this technology is becoming a necessity in an increasingly digital world where data is generated all the time. As it relates to the Digital Twin, Big Data proposes refined processing over high amounts of data linked to the Digital Twin.

3D Scanning

3D scanning is one of the techniques that most benefits from digital twin technology. Through it, it is possible to replicate and digitalize large-scale physical environments with high accuracy from real images collected in the field and which are later linked into 3D digital models.

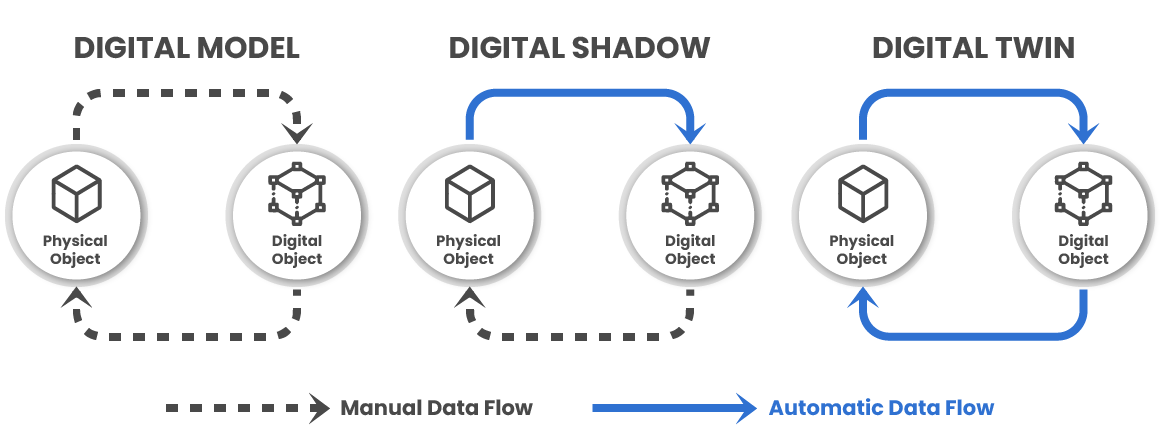

The digital twin can be classified into 3 different types. However, the level of connectivity is an important factor in its classification, so there are many digital twins that do not necessarily have the same level of connectivity as the authentic model advocated by Grieves and that are not rarely confused with the Digital Twin.

The 3 definitions of Digital Twins are:

Digital Model

The Digital Model does not automate the exchange of data from the physical model to the digital model. All data exchange is done manually, and no change in the state of the physical or digital model has direct consequences for either.

Digital Shadow

Unlike the Digital Model, here there is an automatic flow of data from the physical model to the digital shadow. A change in the physical object can interfere with the digital one.

Digital Twins

There is a flow of data between the physical element and the digital element, and vice versa. Just like the digital shadow, the physical can control the digital, but also the digital can interfere with the physical. This fully integrated constant flow is what makes a Digital Twin a Digital Twin.

Where can a Digital Twin be applied?

One of the reasons that the digital twin has become such a big business trend is precisely its high flexibility for applications in different industries and for different purposes. Although there are already several application fields for this technology, new ones are emerging every day. Among the main applications are:

Industrial

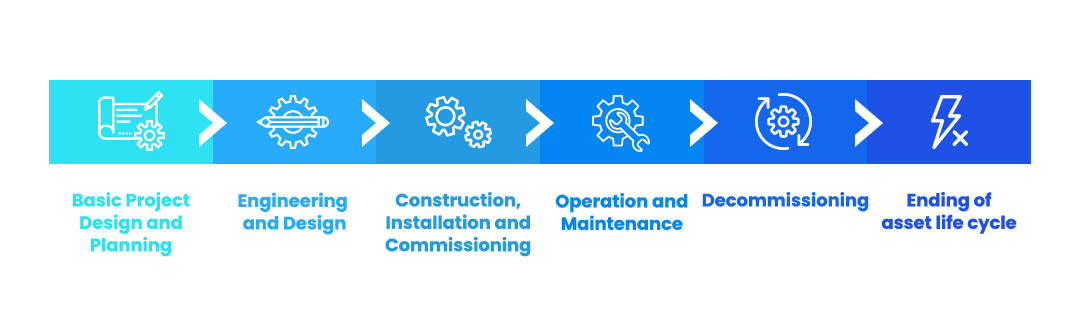

Industries can benefit from this technology to improve their structure, processes, and operations. The technology has been applied on numerous fronts within the industrial sector, from the initial design phases to the operation and maintenance phases, which will be better detailed in the following.

Manufacturing

The digital twin is capable of being applied on production lines even before a physical product is even manufactured. By integrating it with prediction algorithms, it is possible to understand how a product will behave under real-life conditions, thus enabling significant testing and improvement.

Retail

Retail is one of the sectors in which the application of the digital twin tends to expand most rapidly. From intensive data collection, for example, it is possible to understand users’ behavior regarding a certain product. The data processed in the digital twin is used as a basis for decision-making that can result in improvements in user experience.

Smart Cities

As one of the most amazing applications of digital twins, smart cities centralize all infrastructure and service management on its platform. Through Digital Twin processes become faster and more accurate. In addition, resource management can be optimized and sustainability plans can be executed on a large scale.

Health

From the creation of a digital twin of a person, we can understand their behavior, how their habits influence their health, the behavior of their systems and vital signs, and even the prediction of a disease

Click here and understand in detail 4 types of Digital Twin applications!

What kind of benefits does Digital Twin provide?

The large increase in demand for Digital Twins in the business sector only demonstrates the great benefits that this technology can provide. Among the main advantages of using a digital twin we can mention:

Predictive Analysis

Understand the future behavior of an asset, equipment, or product under specific conditions. This feature allows optimizations about product development to be made even during its development phase.

Access and understand how Digital Twin can predict costs

Process Optimization

Identifying process improvements, bottlenecks, and inefficiencies that might go undetected without digital assistance.

Risk Analysis

For industries that have operations that involve risks, a digital twin is a great tool for analyzing risks to people and assets. With the help of this technology, dozens of accidents can be avoided.

Resource Savings

One of the main benefits for any business sector. From the knowledge generated by the digital twin, it is possible to understand how resources are being used, if they are being efficient or if they need some kind of adjustment.

Simulations

The aeronautical industry is one of the sectors that benefit most from simulations. It was even in a simulation made by NASA in one of its spacecraft that the first real application of Digital Twin was performed. From simulations, we can establish conditions for test execution, without having to use a real product.

What is its importance to the industrial sector (Operation and Maintenance)?

The model proposed by Michael Grieves has as a fundamental characteristic: interoperability in all phases of the asset lifecycle (PLM), despite this, it is worth highlighting the application of this technology focused on the operation and maintenance phase, specifically.

In complex industries such as process industries, for example, the integrity manager (the discipline responsible for the maintenance and inspection of assets) has many challenges.

Since they have a large number of assets, the person responsible must plan maintenance and inspection days, and in turn, operators need to scour different systems in search of manuals and procedures to perform the task.

Normally, these industries have a closed budget for the execution of these activities, that is, if some unforeseen failure occurs, the person in charge must solve the problem based on his available resources.

The execution flow of maintenance and inspection activities in this scenario opens gaps for the disorganization of information among teams, systems, and decision-makers, besides possible inefficiencies in the execution of activities. There you have the opportunity generated by the Digital Twin technology.

Applied in the maintenance and operation phase, an authentic digital twin is able to centralize all information related to the workflow of asset integrity management programs in a single system. Obtaining all the necessary information for the execution of inspection and maintenance journeys, besides making the activity more assertive, it requires less effort and time from the workforce.

Besides the interoperability feature of the tool, the digital twin can visually favor the allocation of resources. Because of the continuous data flow, you can establish areas of higher risk and stagger activities among operators for inspection.

Operators, in turn, can automatically synchronize information gathered in the field to synchronize the model.

Finally, the technology can be equipped with Artificial Intelligence algorithms that, besides processing and contextualizing the extracted data, can be able to generate outputs such as the budget needed to perform maintenance and inspection activities, and estimated time of asset degradation, besides simulations of specific scenarios to the operation.

Certainly, the industrial sector has much to gain with the implementation of this technology in its processes and operations. Specifically, in the operation and maintenance phases, the use of a digital twin can mean less risk, greater efficiency and productivity of teams, total control over the operation, and greater profitability.

How does a digital twin work?

We already know that a digital twin is characterized by a continuous flow of data between real and digital assets, and cooperates with technologies such as IoT, AI, and Big Data.

But there is still a fundamental process for all this to actually work.

The flow of a digital twin is fed by different types of data, coming from multiple sources. All this data needs to go through a process of contextualization, which is organizing it into specific contexts so that it can generate meaning.

In the contextualization process, three questions are fundamental: what is this data, what is it used for, and who is it for?

From this data treatment, the digital twin can process this information in its database and generate outputs that will be used for decision-making by managers. Understand the concept of Data Contextualization and how it has become indispensable for industries by clicking here!

What are its prospects for the future?

According to a report published by Business Wire, a world reference in enterprise sector research, the digital twin market is expected to reach $4.8 billion by 2027.

The research also indicates that the use of digital twins is expected to become standard by 2028, in addition to an extensive movement towards integration with API’s and different information systems.

How quickly can it be developed?

The time required to implement a digital twin is relative to the size of the project and its application. There are also specialized digital twin implementation services available for those who wish to enjoy the multiple benefits of this technology.

Here at Vidya, we have been able to develop and implement a Digital Twin platform for the maintenance and operations phase of process industries in a matter of weeks, and best of all, it can deliver ROI in less than one year.

Conclusion

A digital twin is a revolutionary technology that has created great opportunities for a wide variety of business and industrial sectors. Voted as a breakthrough technology by Gartner in 2019, the Digital Twin has been gaining more and more relevance among investors and stakeholders thanks to the great benefits generated.

The concept of the technology is that of a virtual representation that mirrors a physical object with constant real-time data flow from that object, which can be an asset, a machine, or even a process. The concept is the result of a search for continuous improvements in the development of projects, products, and engineering activities and has revolutionized the digital market in a short time.