The digital transformation has been expanding the horizons of industries in search of better performance in their processes and operations through the use of cutting edge technology.

The use of these technologies, which has been popularized in recent years, and is increasingly gaining space within industries transcending the complexity of operations, generating results, opportunities for optimization, and above all, adding value to the production chain, taking many industries to a new digital age.

Understand in detail what digital transformation is, what its applications are, and technologies that mark this period of extreme importance for the industrial scenario. Click and access our article.

TECHNOLOGY ASSISTED SOLUTIONS

Industries have been adapting to a new digital age, gradually. Little by little new technologies are gaining new applications and are adapted to the specific scenario of each operation, generating automation and control over several variables and tasks that had been performed manually.

However, there is still a long way to go for many industries before the new digital age is actually reached by the industrial sector.

It is the complexity that involves industrial processes that is the main obstacle between industries and digital transformation. It is in order to make these technologies applicable to operations that many software have been developed and have been adapting these technologies to applications within industrial plants.

INTEGRITY MANAGEMENT AND DIGITAL TRANSFORMATION

Asset integrity management is an extremely important discipline for industries and has a huge potential for upgrading performance and assertiveness with the help of digital transformation.

We have extended content talking about the main concepts of asset integrity and how the activities that involve this discipline are performed. Click and watch.

Having the integrity control of assets in a plant, where the number of assets can easily exceed 500,000 is a virtually impossible task to be performed manually, and it is in view of this problem, and the importance of having effective integrity management that digital transformation presents tools that can take the discipline to another level and generate a disruption with current methods of execution.

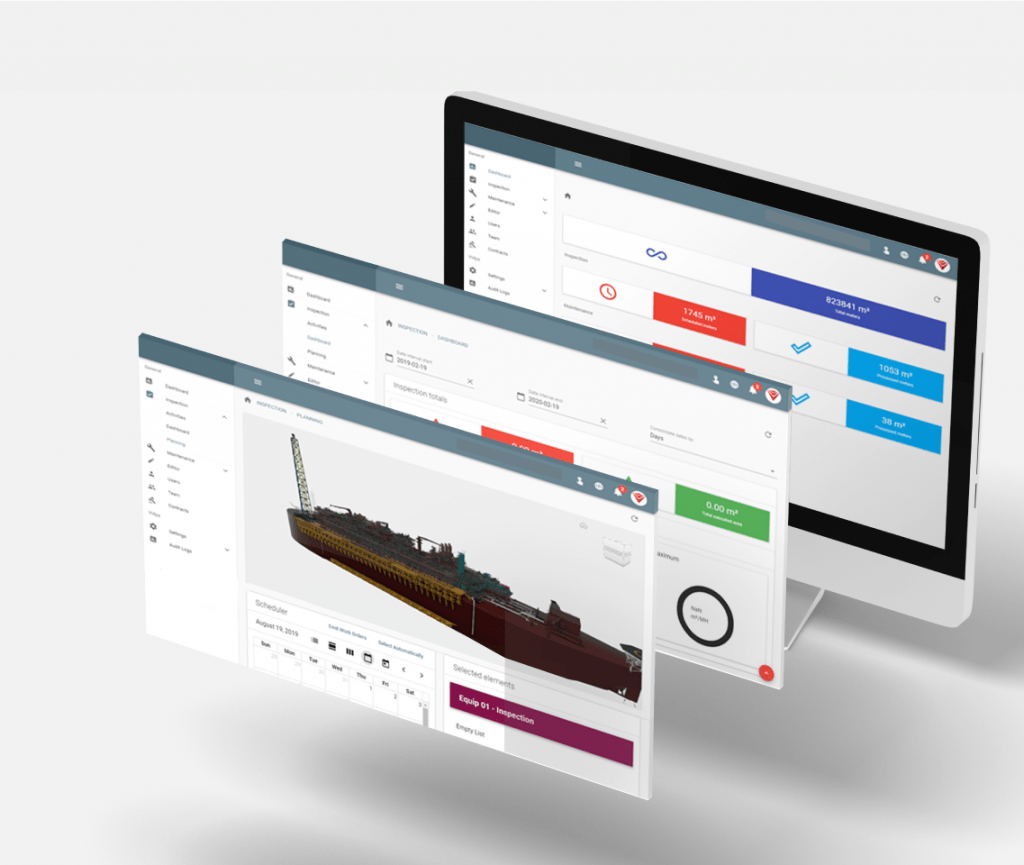

It is with the use of Digital Twin and Artificial Intelligence that automation starts to happen. Through a digital twin, the control and visualization of the assets become fast, contributing positively to the location of mechanisms of failures or loss of useful life that can cause accidents. In addition, the use of Digital Twin allows a continuous flow of information between real and digital assets, thus enabling an overview with real data.

With the use of artificial intelligence, integrity management can reach even higher levels. Failure predictions, levels of corrosivity beyond the standard, and even task scheduling between teams are now possible with the use of AI.

These are just some of the many possibilities generated by the digital transformation for the asset integrity discipline. It is with the use of tools that make use of these technologies in their systems that industries have the possibility to reinvent themselves, overcome adversity, and generate results.

Find out how Vidya software proposes to deliver intelligent solutions for asset integrity management with cutting-edge technology and which has the potential to generate expressive results within complex industrial operations. Click and access!