Inspection and maintenance tasks in industrial plants are extremely important for the proper functioning, guarantee of safety, and continuity of an operation. Thanks to Digital Transformation these activities can be enhanced through Digital Twin and Artificial Intelligence.

The discipline responsible for managing these activities is known as asset integrity management.

Among the main duties of this discipline are:

- Identification of failure mechanisms

- Identification of loss of performance in assets

- Management of inspection and maintenance teams

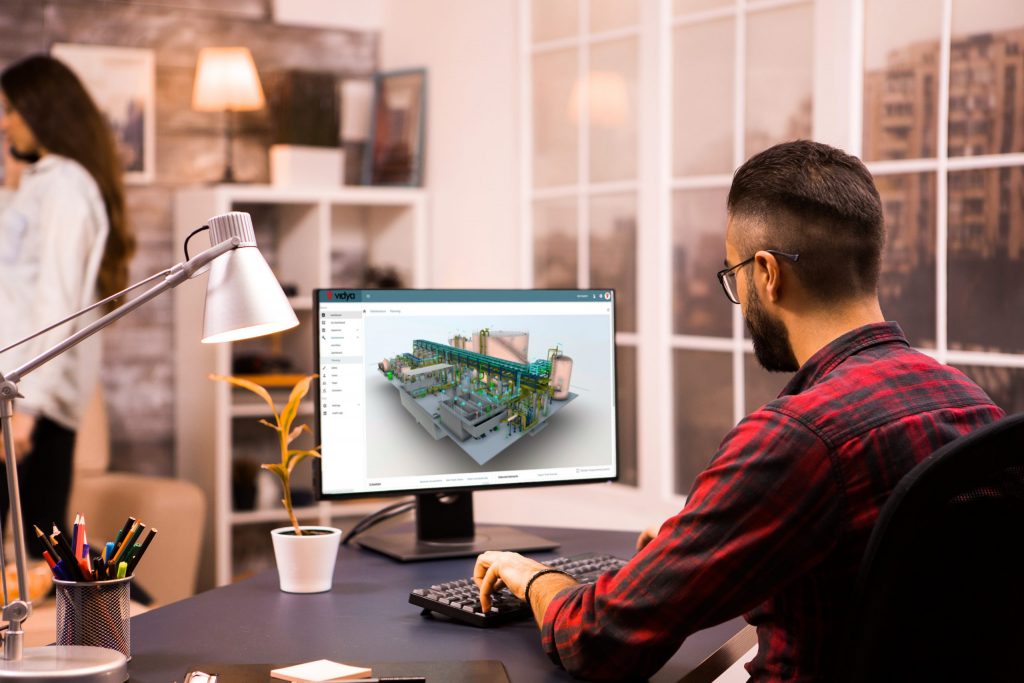

We can understand the essentiality of this discipline for the proper functioning of an industrial plant. However, managing assets can be an extremely exhausting and error-prone task if performed in a decentralized manner. The lack of integration between these platforms and the lack of centralization of information makes the analysis on assets to be monovariable. The purpose of Digital Twin is to integrate, centralize and bring a complete situational awareness of the plant so that the analysis is multivariable.

Having digital systems that support this discipline is essential in a period when industries are increasingly integrating digital transformation technologies into their operations.

Read: the fundamental aspects for efficient asset integrity management.

ASSET INTEGRITY AND DIGITAL TWIN: TOTAL CONTROL ON INTEGRITY

The industry has the possibility to generate greater value and safeness to its operations through systems that make use of Digital twin technology. Simply put, the digital twin is a virtual replica that receives a continuous stream of data from its real twin. With this technology it is possible to have access to data in real-time, which can be very beneficial for everyone who works in industrial plants.

Read: Digital Twin: the main concepts behind this technology

The possibilities generated by this technology for asset integrity management have been attracting great attention from the industrial sector. In a report by Gartner, it is estimated that Digital Twin will be used on a large scale in the coming years and that at least ⅔ of the industries that use IoT (Internet Of Things) will have at least one Digital Twin in their operations.

The digital twin can be applied for different purposes within a plant, process, or even a machine. However, when we analyze the advantages generated by this technology for the discipline of asset integrity, the gains are overwhelming.

Between them:

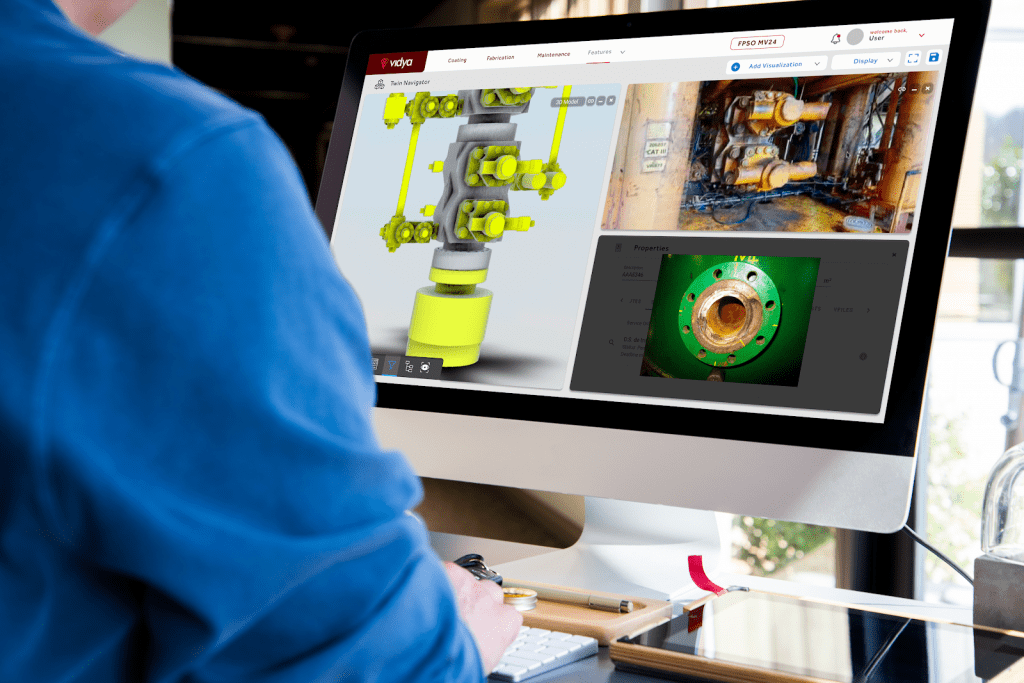

- Real-time visualization of asset health

- Schedule of inspection activities

- Prediction of time performed in maintenance

- Identification of areas with greater degradation

- Budget Planning

These are just some of the main advantages generated by Digital Twin in integrity management tasks. Just as each operation has its singularities, it will also be with the application of Digital Twin in each operation. Solutions equipped with Digital Twin Technology tend to be highly customizable according to the specific needs of each industry.

In addition, the intersection between Digital Twin, IoT (Internet of Things), and Artificial Intelligence further accentuates the performance possibilities geared to asset integrity management. The result of the link between these technologies is the dream of any industry that aims to digitize and automate the management of this discipline in its operation.

Through the combination of these two technologies, it is possible to generate knowledge of value for decision-making based on the prediction of scenarios established by data calculation.

The importance and essentiality of good integrity management is already inherent in the industries and now more than ever the discipline can have its performance boosted by Digital Transformation. Specific needs of the operation provide better resource management, team scheduling, and greater flexibility will be the path to digitize the management of asset integrity in industries.

Get to know these tools by clicking here.