Digital Twin technology can predict risk and cost in 2021, through asset integrity awareness. Keeping the integrity of industrial assets is an essential task for any industry especially Offshores, Refineries, Oil & Gas, Pulp and Paper, Mining among other complex industrial plants.

However, some challenges can appear in the process of inspection and maintenance of these assets. Such as:

- Lack of a complete and updated inventory of the complex plant;

- Difficulty in outlining a maintenance budget;

- Time-consuming inspection tasks;

How could asset awareness be achieved?

Until the operational phase of the complex plant, many engineering data , technical drawings, and database, were generated in the firsts phases of the PLM (Project Life-Cycle Management), but not always these rich data are available for the handover of the project in the Operational and Maintenance phase (O&M).

These engineering documents can offer advantages for who’s responsible for asset integrity management. Like knowing if scaffolding or irate are needed to inspect and maintain certain components and assets. Besides, it can provide many other crucial information about the life-cycle of the material. Offering a complete inventory for who operates the plant.

Vidya Technology, is a group of specialized engineers in asset integrity management. They realized the potencial of automation, centralization, and optimization of asset integrity management through Digital Twin technology. By the development of Vidya Software they learned how to recover and organize all paperwork generated in the firsts phases of the PLM with the digital twin technology. In that way, all the documents that were designed in the engineering phase are collected and combined with Artificial Intelligence. And through Machine Learning, predictive algorithms, and other smart features, integrated and centralized in a single platform.

How does it works?

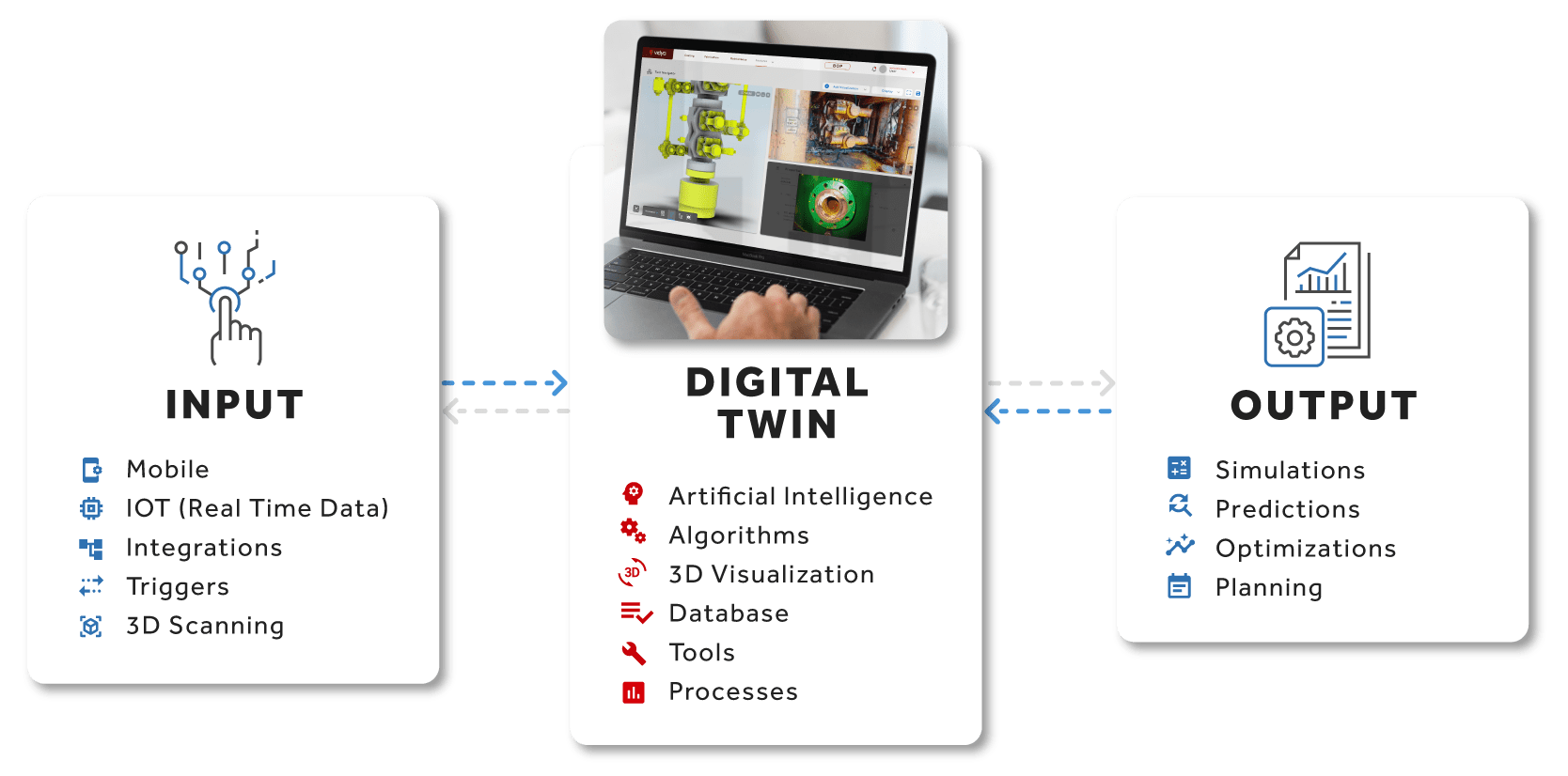

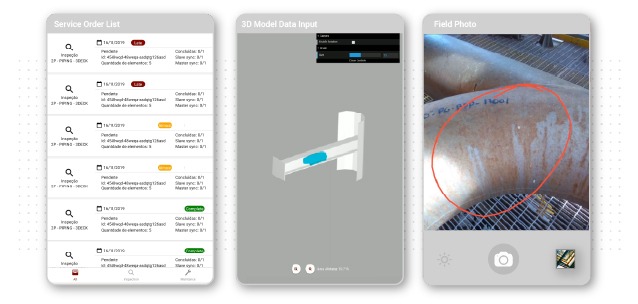

The Digital Twin we talk about as a trend in 2021 receives information about the physical object and vice-versa, creating a continuous flow of data. Having a complete inventory of the plant, the Digital Twin works in a system of inputs and outputs. The field team responsible for asset inspection utilizes a tablet with custom checklists synchronized with the digital model. Implementing inputs through the tablet, with screenshots, forms, and photos, or even marking degraded areas directly on the 3D model.

Firstly, the digital twin receives that information. Secondly, utilizing data from the life cycle of the material determines, together with the technology of Machine Learning and predictive algorithms. Warning you when other components from the same material will need maintenance. This constant cycle teaches the digital twin how to understand your plant, enabling predictive maintenance of industrial assets.

It’s also possible to personalize all the software systems based on the unique characteristics of your operation.. You can register new attributes and create checklists accordingly with the asset management execution plan itself, being the ideal software for any complex industrial plant.

The results

Through this technology, it’s possible to decrease maintenance costs and risks. For instance, you can simulate and calculate the asset life cycle. And manage all the work orders from a single platform. In that way, you can have 100% control over the teams working on the plant. And even reduce 30% of the people working on the field for activities of maintenance. In conclusion, exposing fewer workers to the risks of this activity.

The connection of a predictive maintenance – the safest for industrial assets and at the lowest cost in the long run – with the digital twin that centralizes information, brings the result we did with the last survey done by Vidya: 25% savings on asset maintenance in 10 years campaigns, a 50% increase in the productivity of maintenance teams, and 66% people reduction on field.

Your operation can be more efficient, safer, and at the lower cost using Vidya Software! If you want to know more about our solution, you can contact us or make the download of the presentation of our results here.