The Industry 4.0 is a revolutionary movement that has provided increasingly interconnecting components to the industrial sector through the use of technology. Among the several tools that emerged from this movement, one has been calling the attention due to its revolutionary outcome: The Digital Twin.

This technology is being used in industry to raise productivity by planning and optimizing the process of collecting and analyzing data through a continuous flow of information between a real asset and a digital replica.

However, this technology can work in many different ways, and it is necessary to understand its specificities to achieve better results with the software application.

Want to deeply understand the Digital Twin technology? Access the article

What is a Digital Twin?

This technology has in its essence the main pillars from the Fourth Industrial Revolution, being digitized, decentralized, modular, and allowing real-time operation to get the most customizable and optimized outcomes.

The Digital Twin was originally designed by Michael Grieves in 2002, to be used in the Project Life-cycle Management (PLM). Even though the Digital Twin is still being used in this area, other companies have also discovered the value delivered by this technology to the improvement of their process and operations. Here we have two examples of Digital Twin applications:

- NASA in the research for aircraft conditions predictions on a launch environment

- Healthcare system, with researchers pointing to Digital Twins as the medicine of the future – a fully personalized healthcare.

Nevertheless, it is necessary to differentiate the concept of a Digital Twin from a simple simulation. While in a simulation there is the creation of a scenario of what may happen to a product in a given circumstance, the Digital Twin represents what is actually happening in real-time in an asset, thanks to the continuous exchange of data between the real and virtual environments.

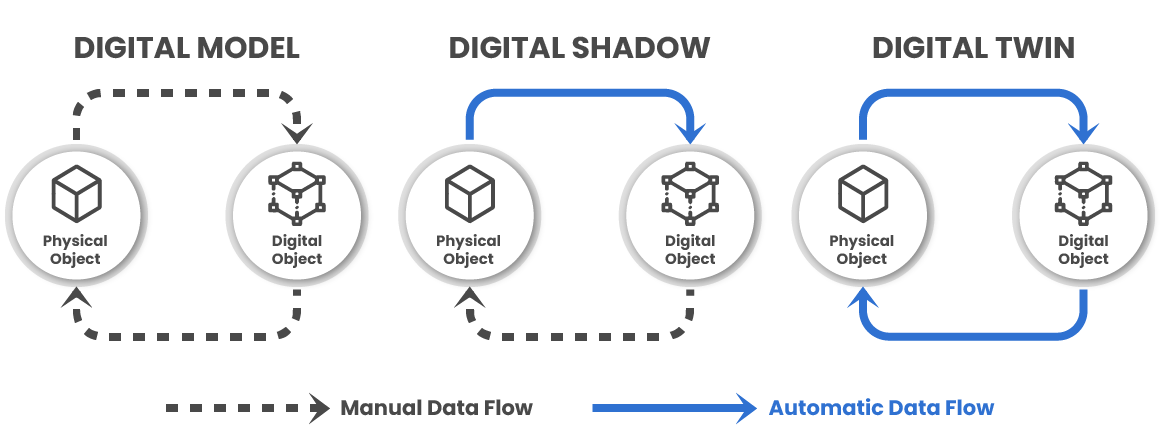

Digital Twin levels according to the ability to exchange data

Digital Twin can be used in many activities, the technology has a lot of different concepts surrounding it. From all these definitions, researchers from the Fraunhofer Austria Research GmbH differentiate them from the level of integration of the technology with the real world. All of them have in common the digital representation of an existing asset, and the distinction is the ability to exchange data. That being said, these are the 3 main models:

- Digital Model: The Digital Model doesn’t automate the data exchange from the physical to the digital model. All the data flow is done manually, furthermore, no change in the state of the physical or digital model has direct consequences in both of them;

- Digital Shadow: Differently from the Digital Model, it has an automatic flow of data from the physical to the digital shadow. A change in the physical object can interfere with the digital, but the opposite does not occur;

- Digital Twin: There’s a flow of data between the physical asset and the digital and vice versa. As the Digital Shadow, the physical can control the digital, but also the digital interferes in the physical in this case. This constant flow fully integrated is what makes a Digital Twin.

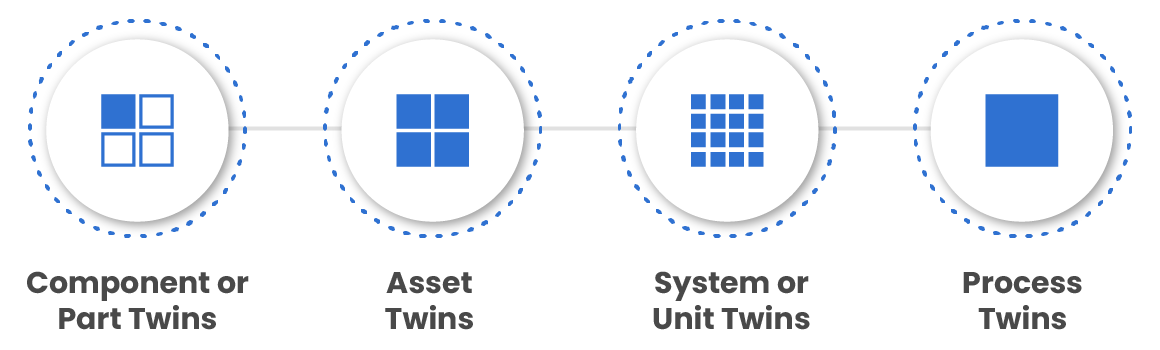

Types of Digital Twin

Understanding what a complete Digital Twin represents, it is possible to distinguish the different application areas of the tool in an industry, which are divided into 4 main types:

- Component/Part Twins;

- Asset Twins;

- System/Unit Twins;

- Process Twins.

Component/Part Twins

This type of Digital Twin represents the model of an individual part of the production system. Although it is more common to use the technology on a larger scale, it is still possible to apply the tool to more relevant units of the operation.

Asset Twins

By combining the application of the technology in different components that are connected, the Asset Twin is formed. In this case it is possible to understand how different parts of a system interact and generate more concrete actions from the processing of the data provided by the analyzed elements.

System/Unit Twins

The next level of Digital Twin application is represented by the union of different Assets that enable the analysis of a complete process within the operation. The insights generated at this level are much more complete, since it is possible to understand the consequences of a situation on a larger scale across the industry.

Process Twins

Finally, we have the most complete Digital Twin model, which covers all the systems of an industry to represent its operation from start to finish. The Process Twin allows you to integrate the data generated all the time in the industry so that you can make decisions more assertively and make processes more efficient.

What results does this technology provide?

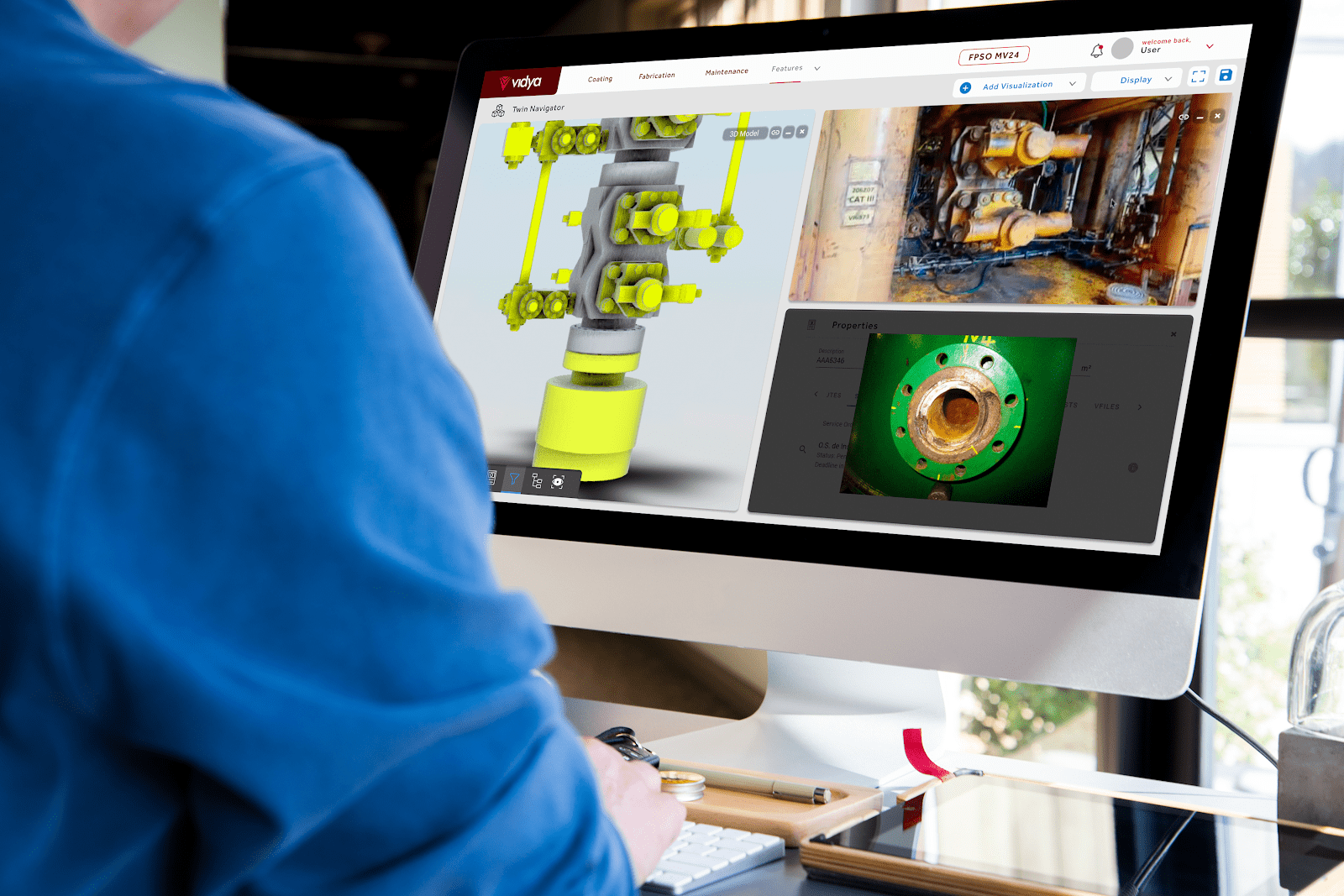

Although the majority of articles and papers use the term Digital Twin a few of them really follow the definition. The adoption of this revolutionary technology in industry can increase the effectiveness of an operation, offering lots of benefits. Based on these parameters, Vidya is part of this small group who provides a real Digital Twin. Using our platform the following results could be achieved:

- 100% control of the asset and the team in real-time;

- Increase of 50% in the maintenance and execution of team productivity;

- 30% reduction of people in the field;

- Evaluation of machine conditions based on descriptive methods and machine learning algorithms;

- 75% savings on time to reach data and information about assets;

- Predictive maintenance based on the forecasts made by the system based on the gathered data from the operation.

Vidya manage to reach all these results centralizing engineering data, 3D models, technical drawings, and databooks, generated on all phases of the PLM and combining different cutting-edge technologies such as Artificial Intelligence, Machine Learning, and IoT to create the Digital Twin.

In this way, we connect all the previously contextualized data in a cloud-based tool with the data that is being generated in real time by sensors and tablets used on the field. This way it’s possible to identify and gather valuable information from the asset, such as degradation state and efficiency, improving inspection and maintenance activities.

Conclusion

Knowing the types and applications of the different Digital Twins allows you to understand the potential of the tool, as well as the benefits of the most complete models.

Even in the smallest applications, such as in just one Asset, to those that cover the entire process of the industry, this technology provides an increase in productivity, equipment efficiency, safety, and especially profitability.

Access to understand the trends for 2023

From the use of Digital Twin, you’ll have the ability to control asset integrity status, manage inspection and maintenance operations, and predict the life-cycle of the material for example. It is an important industrial process improvement that can save a lot of the maintenance budget.

Do you want to know more about our results and how our Digital Twin Platform works? Download our Digital Twins Portfolio in the form below!

Want to see it in action? Access our use cases