Digital transformation can integrate the phases of the PLM (Project Life-Cycle Management) through documents and data automation, resulting in more effective results. Therefore, avoiding known problems, as a fragmented data system. I’ve talked more about the PLM in my last article, about Inventory, you can click here to access it.

Piles of documents, technical drawings, and spreadsheets, were produced in the Design phase. However, until the Operation and Maintenance phase, crucial information can be lost. Therefore, the importance of keeping the entire process documented is that projects related and interdependent to each other don’t get missing. Besides, the design project can also change during the Construction and Manufacturing phases. By replacing materials, changing technical characteristics of components, or repositioning them, for instance.

All this information and dataset is directly used by the manager during Construction, Manufacturing and Comissiong, consolidating different projects, from diverse areas, executed by different companies. For this reason, industrial plant constructors must have access to all the documents and maintain a schedule of materials receipt, but part of this data is lost when it comes to the next phase: the Operation and Maintenance, or O&M. Rich parts of the data produced and delivered in the EPC phases doesn’t get to the operation responsible for the handover of the plant. So the operator does not take advantage of the results that these data could bring, if correctly employed.

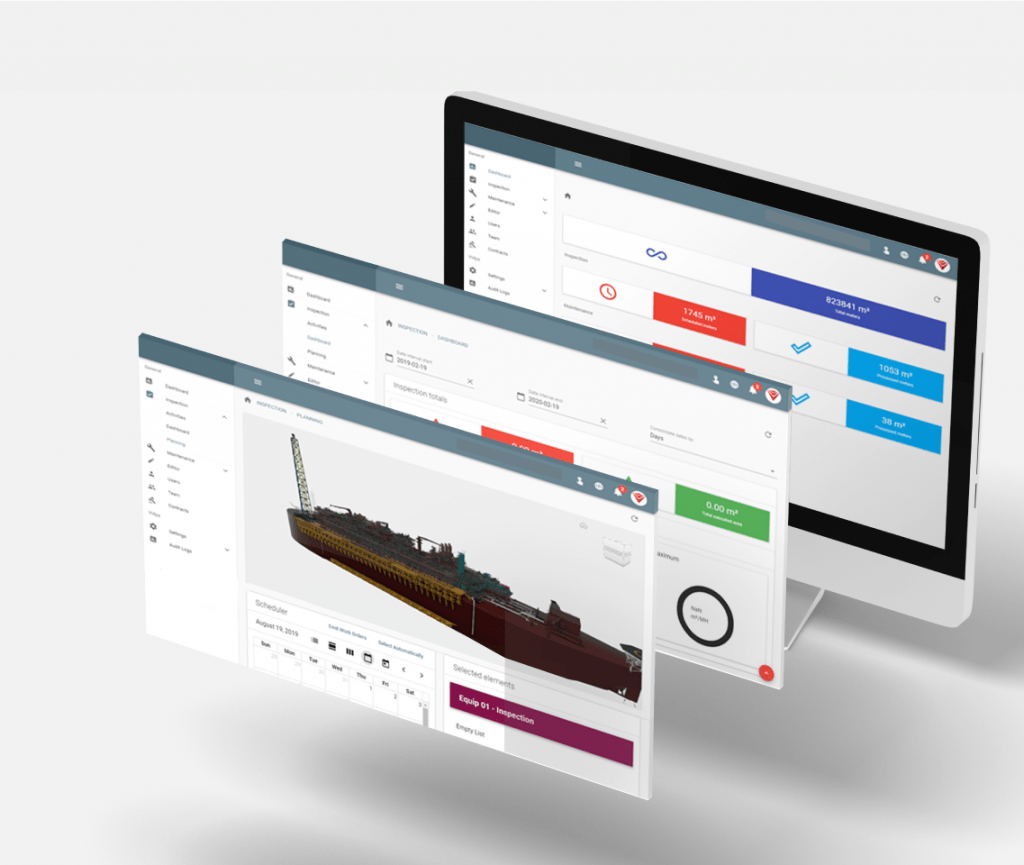

Vidya realized a way to provide greater part of data produced until the O&M through digital technology. For example, one of our richest data sources is the 3D design of the industrial plant, which can be taken to the O&M phase. Consequently, it provides more accurate information as location, coating color, material life cycle, among others. With innovative technologies, like Artificial Intelligence, Digital Twin,), among other cloud-based tools, we manage to unite this rich database in a single platform, Vidya Software.

How does the Vidya Software works?

In that way, you can link information such as materials specification for each element, dimensions and geometrical data, engineering dataset, documentation, and technical drawings, to the Digital Twin created from 3D models from the earlier stages of PLM. Therefore, those informations are accessible to operators and managers of industrial plants. In this sense, Vidya Software can:

- simulate and calculate the remaining life of the elements,

- have easy access to execution plans, manufacturing documents and manuals

- see the location of the assets for maintenance,

An important feature of the software is the VFiles. It centralizes documents collected and relates them to the 3D model. Therefore, you can select any element in the 3D model, and have access to the attached document. Among many others, some examples of those documents can be: technical drawings, procedures, and technical standards. As result, it improves maintenance, inspection, operation and engineering data search, making the whole process more efficient and fast.

According to an article produced by Manufacturing Net, about why is PLM so important to high-tech manufacturers, they highlight some problems that could be avoided with a good PLM management, including the data system fragmentation:

“These firms need to create centralized data owners and management systems. By doing so, they increase accessibility of accurate, timely and reusable data throughout the business. This increases process efficiency and re-use of product development data and, therefore, investment dollars.”

Lots of managers already use document management systems, how can they benefit from Vidya Software?

Vidya Software offers a centralized data platform. This is one of our main characteristics: Vidya platform is ready for integration with other systems. Our database is based on the REST API, which facilitates the creation of integrated systems capable to consume from and supply data to other systems such as:

- Management Systems;

- ERP Systems;

- Maintenance Management Systems;

- Engineering Documentation Management Systems;

Therefore, you can integrate the database already used by the industrial plant manager with the Vidya database. Through the integration, Vidya Software database gets substantial and powerful. And using Digital Twin technology, it brings a constant flow of information from the physical object through inspection inputs, to offer maintenance outputs through the digital model. As so, all your documents are accessible and updated in real-time.

Vidya Software offers you 100% of control over your industrial plant in a centralized, integrated, and real-time updated platform. It means more accessibility to element data, bringing more efficiency to the industrial process.