Vidya was born with the premise of guaranteeing intelligent solutions for industries that needed greater control over the integrity of their industrial assets.

It was thinking about the great challenges faced by the Oil and Gas, Petrochemical, and mining industries, that our team of integrity specialists developed the solution that has led large industries to achieve better results, with the optimization of processes that were previously done manually.

VIDYA SOFTWARE AS A SOLUTION FOR BETTER RESULTS

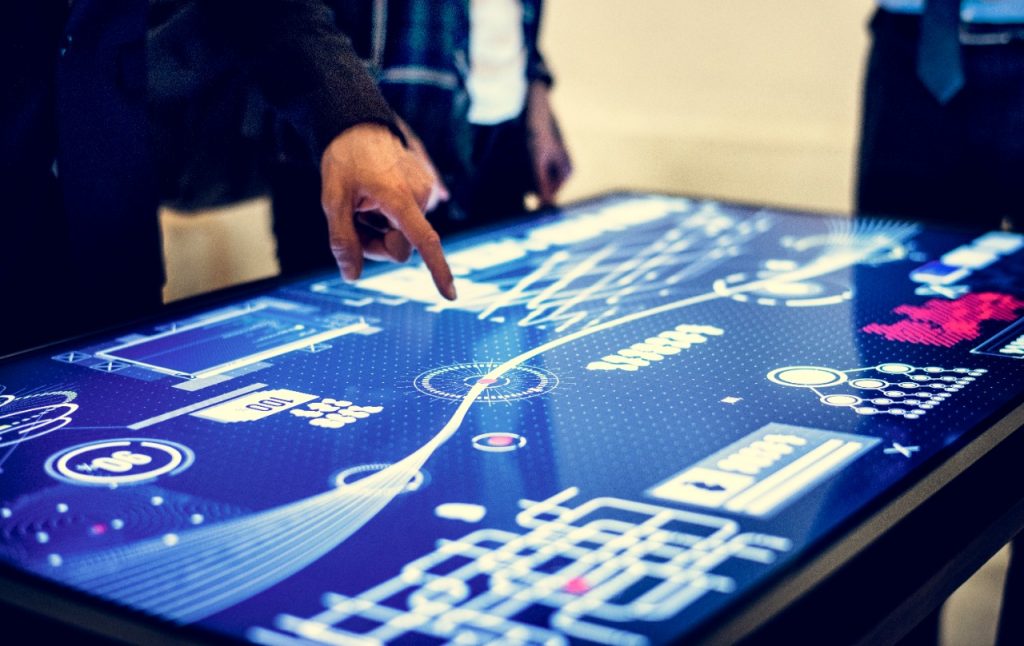

Vidya’s software aims to ensure broad control over the integrity of industrial assets in plants with a high degree of complexity. Through the use of Digital Twin technology, which consists of extracting real data in a digital system, enabling a continuous flow of data between the real asset and its digital representation, which, aligned to the 3D model, allows easy access and visualization on the health status of each element to be analyzed.

The extraction and processing of data on assets can be done through computational artificial intelligence techniques, which make the processing of massive amounts of data viable. In addition, information captured by the operators themselves can be linked to the 3D model, such as field photos and engineering documents.

Using all this information, the 3D model digitally replicates the real status of the real plant. From this, you can have access to analyzes and simulations of scenarios that demonstrate the level of degradation of the components, their remaining lifetime, and even the budget necessary to carry out activities related to inspection and maintenance.

VIDYA SOFTWARE AS AN ALLY IN INSPECTION PLANS

Complex plants such as those mentioned above have large amounts of elements to be inspected, arranged in thousands of square meters. There is also the difficulty of getting around, scheduling tasks and using equipment that is difficult to handle within these gigantic facilities.

Vidya Software proposes a digital revolution for performing these inspection tasks.

From the 3D model, lists, checklists, attribute schemes, and inspection plans can be created with the specific variables of the operation in question. In them, we can register information such as thickness, degree of corrosion, various measurements, cost of execution, steps to be performed within a specific inspection discipline, among other information that can be customized according to the needs of the industrial unit.

The software also enables the automatic calculation of the time required to perform the inspection on the selected elements, facilitating the scheduling and redistribution of service orders between the teams. In the task scheduling function, it becomes very easy to see which tasks are in progress and the demand of the teams in a period of time. Then, the inspection procedures are sent to a tablet to the operators in charge, who can have access to information, data, procedures, and documents in the field to carry out their activity, and also acquire quantitative and qualitative data, photos, 3D markings through the tablet, and automatically synchronize them with the Digital Twin on the Vidya Software base. The program also allows for routing, ensuring greater efficiency in inspection activities with many components, generating routes optimized according to specific inputs, such as distance between elements, for example.

This new model for the execution of inspection tasks has enabled a high degree of optimization, shorter execution time and the need for fewer people involved in the field, being used in routine thickness measurement inspections, visual inspections, NDT inspections and many others .

As we mentioned earlier, this type of activity takes a lot of time and personnel involved, if performed by traditional methods. However, with Vidya Software, the number of man-hours required for inspection activities can be reduced by 60%, or if we only count the number of operators exposed to field activities, a reduction of 66% can be expected. And, of course, 100% control over teams, documentation, work plans, traceability, process steps, and integrity status over industrial assets.

Talk to one of our specialists today and understand how Vidya Software can help your operation. How about being part of this select group of industries that do differently?

Click here to understand more about how Vidya Software will make digital transformation happen in your industry!

Vidya Smart Technologies, for Smart Industries!