Maintaining industrial asset integrity is essential to guarantee the worker’s safety on the industrial plant, and avoid environmental incidents. According to Ralph Rio, vice-president of ARC Advisory Group, the asset integrity needs to be managed since the first phases of the PLM (Project Lifecycle Management), concerned with the material lifecycle of each element. Inspection, he points out, is just one of the steps to run a quality asset management program, since it must also include:

- “Risk Based Inspection strategy (RBI)

- Pipeline integrity management typically for corrosion

- In-service inspection with routine and specialist non-destructive testing (NDT)

- Reliability centered maintenance (RCM)

- Condition-based maintenance

- Vibration induced fatigue failure solutions”

In that way, technologies can control, optimize and make the industrial production more sustainable. Some of the technologies that we can highlight are:

- IoT (Internet of Things),

- Artificial Intelligence (AI),

- Machine Learning,

- Digital Twin and other cloud based tools.

The market of these industries technologies are increasingly developing with innovative companies figuring out new uses and integrating those tools in cloud-based platforms, besides improving these existing technologies.

Accordingly to the “Global Market Insights”, the AI sector is expected to grow by around 40%, followed by the Digital Twin technology, growing 28%, and the IoT, by 19% growth in the same period (2019-2026). It shows an interest in the global industry to invest in digital technologies that bring more efficiency through data automation for industrial manufacturing.

Vidya Technology proposal to industry innovations

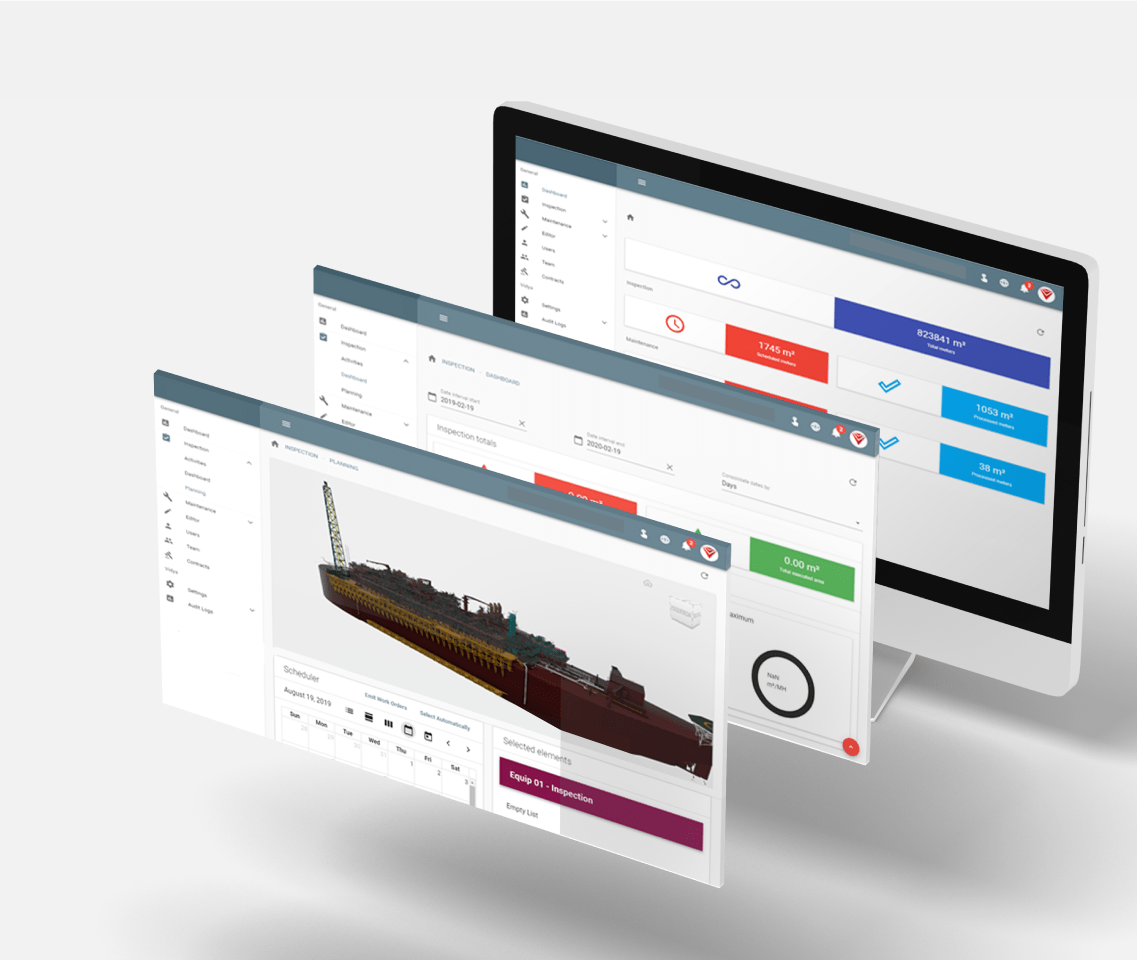

Vidya Technology is one of the companies that invested in this global tendency. Adopting those technologies and developing asset integrity management solutions, Vidya Software has characteristics such as remote team management for the industry (focused on the distribution and monitoring of inspection and maintenance tasks), besides the inventory digitalization, which can be updated in real-time.

Team Management article of Vidya Characteristics series can be accessed here, and the Inventory one, here. Click in the links to check on these texts!

However, one of the main features that Vidya Software brings is the files/documents centralization and customization of component attributes for each element of the Digital Twin. Therefore, you can link any sort of dataset needed to Digital Twin operation, to any particular element of the plant. Among an infinity of possibilities, some examples of dataset or attribute schemes can contain:

- Dimensions

- Location

- Position

- Types of Structure

- Materials

- Coating

- TAGs

What are the advantages of having customizable attributes?

With customizable and specific attributes we can populate the dataset. In this dataset, for each element, several characteristics can be indicated. Therefore, you can have all attributes needed for each operation you perform using the Digital Twin. For example, using Vidya Software to manage anticorrosive coating integrity, various types of paints and their information are registered as attributes, together with their respective consumption and cost schemes.

The coating management is just one of the several modules that Vidya Technology covers. It’s precisely the customization of the system’s attributes that makes it so flexible and ideal for the most diverse process plants. Therefore, you can centralize the process of asset inspection and maintenance in a single customizable platform.

In this context, you can apply attributes schemes to measurements points, alerts, work orders, plans, and checklists, for example. In addition, this information can be integrated with other systems, since our database is based on the REST API. Consequently, it facilitates the data consumption and supply to other systems, as ERP and management systems.

In conclusion, with customizable element attributes, asset integrity management can be more efficient. If you want to know more about how Vidya Software works, you can download our presentation here.

Thank you for reading our content!