In recent years, new technologies have driven what we now call Digital Transformation. From these new discoveries, many changes started to be part of the industries operation, and consequently, of people’s daily life.

Among the several new technologies, one of them stands out and draws the attention of many people and companies due to its fundamental role and its many functionalities: IoT (Internet of Things).

Next, we will talk a little about the many factors that have made this one of the main technologies in digital transformation, generating new ways of operation and optimization for industries.

The beginning of IoT

The concept was born in 1999 by Kevin Ashton; as a result of research carried out in the Auto-ID laboratory of the Massachusetts Institute of Technology and was only possible thanks to accessing the:

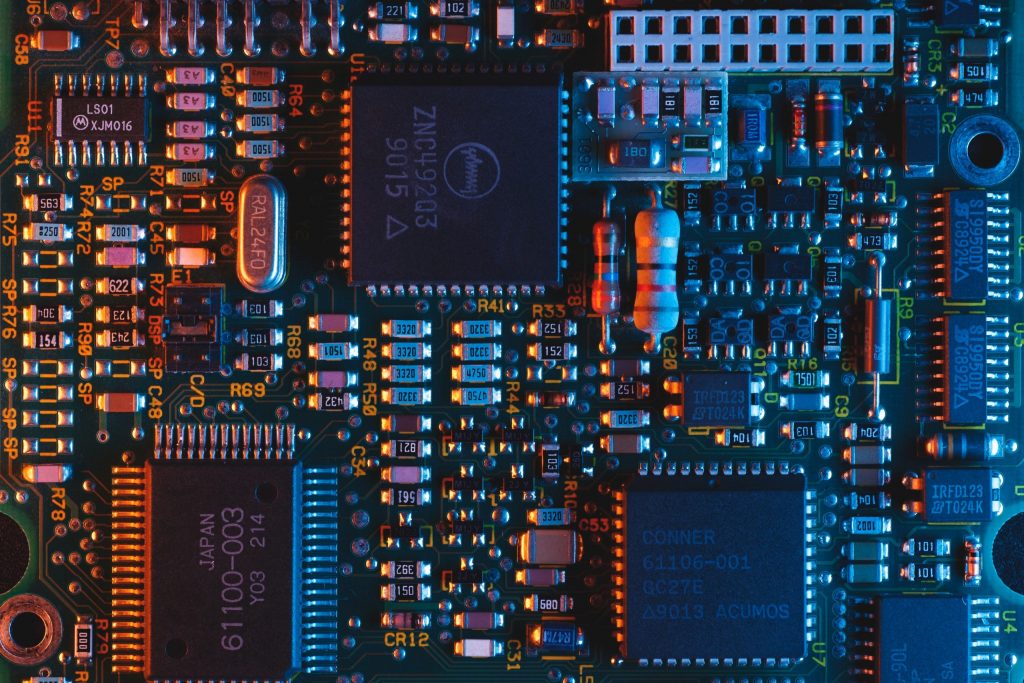

- Low-cost sensors,

- Microchips,

- Evolution from ipv4 to ipv6,

- The constant development of technologies related to cloud connectivity and processing.

In addition to these, we must mention the advances in Artificial Intelligence that were essential in the applicability and development of IoT and enabled the Internet of Things to be what it is today. Along with it, two other concepts have become popular and are considered pillars that supported AI in its development, and consequently IoT, Those are Machine Learning and Deep Learning.

-

Machine Learning

Machine Learning is the ability of a machine, through algorithms, to establish standards and perform calculations based on the information to which they are submitted, being able to establish problem-solving without the need for human intervention. As new actions come into play, the machine uses its previous calculations as a reference and proceeds to trace solutions autonomously.

-

Deep Learning

We can consider deep learning as the attempt to replicate the functioning of the human neural network through more sophisticated algorithms capable of processing large amounts of data in a non-linear and superimposed way, forming a true artificial neural network.

Secrets behind IoT

Well, we can roughly classify the Internet of Things like the ability of devices to communicate with each other without human interference. Such functionality makes it possible to continuously monitor and measure several elements through a connected data network. Thanks to this system, it became possible to know when equipment, part or element, will need repair or replacement.

Another possibility generated is that of turning things themselves into service providers, such as driverless cars, for example. The ability of things to communicate with each other has generated great disruption with manual methods of carrying out activities, proving to be great agents of digital transformation.

How IoT sensors work

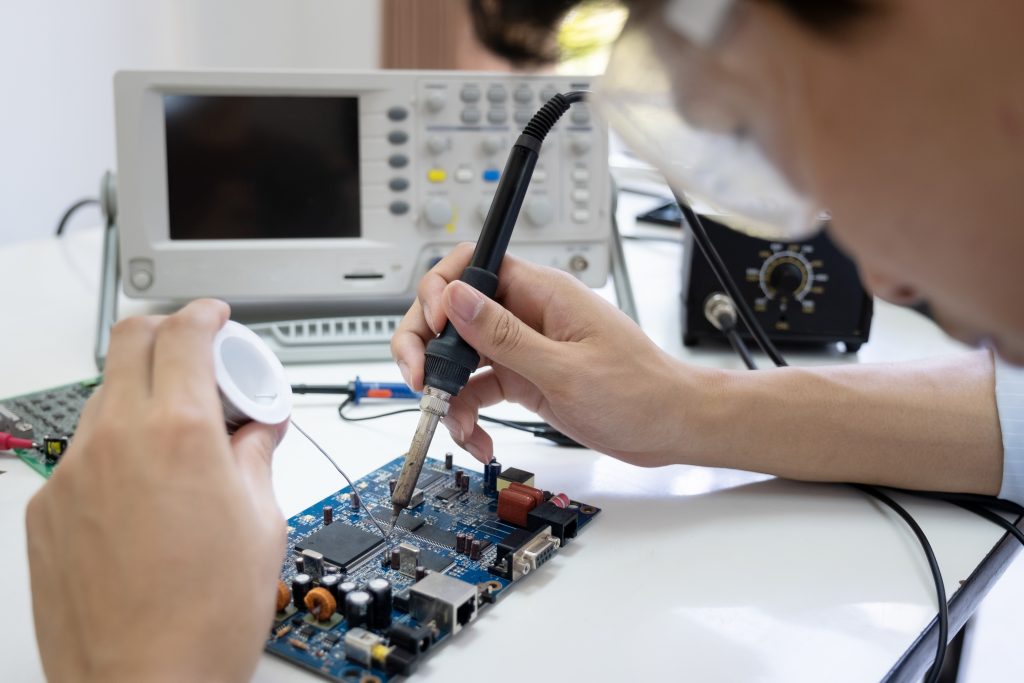

Sensors and microchips are installed in a specific device, part, or asset, and from that point on, data extraction begins, which after being collected are transmitted to an application, which, connected to the internet, will store, process, analyze, and share these data in a database.

Internet is not always necessary to communicate between two devices, they can also be done through dedicated networks and Bluetooth systems. After the collection of this data by the “things” through its sensors, they are grouped and transferred through a hub or gateway and after that organized in interfaces on which the user can make decisions remotely.

Machine Learning and IoT

The applicability of IoT becomes even more interesting when associated with Machine Learning. The data collected and processed by things will later be accessed by the user and the user will make decisions. After some input, the devices are able to learn from the user’s behavior and are able to generate predictive analytics, and thus, automatically make decisions based on the user’s historical preferences.

An example of this are home management applications like Amazon Alexa, and Apple Home Pod.

Through them, various devices such as locks, thermostats, televisions and stereos are remotely controlled through equipped sensors. The data collected by them goes to a database in which the user can make decisions such as:

- Room temperature control,

- List of favorite shows,

- Custom Playlist,

- Home arrival times,

With these inputs, the devices gradually start to learn about their user’s preferences and after some time decision-making starts to be done automatically. Thermostats begin to adapt to the preferred room temperature, the television turns on its user’s favorite programs, stereos recognize musical tastes, and days when its user likes to listen to them.

How does IoT support industrial processes?

The range of assets that can be connected via IoT sensors is immense, and thus, their functionalities will be as broad as their options.

But how exactly does the industry make use of this technology?

With the constant incorporation of digital transformation concepts, the use of technologies such as IoT becomes essential in plants. Industries have made these technologies native to their plants and operations, and gradually new uses and functionality adaptations are found for them.

Due to the high interconnectivity of these elements, it is possible to access high-value information and knowledge that help predict failures, problems, and bottlenecks in a production line. This makes the resolution process faster and more flexible.

With a database being fed by sensors, we can then have at hand the necessary information to seek alternatives and explore with maximum efficiency managerial processes. In this way, we optimize the workforce, and avoid possible interruptions, having in hand the necessary information to carry out inspection and maintenance planning.

The Internet of Things is already used in the most diverse areas within engineering and industry, and can be widely used to:

- Perform logistics management,

- Soil acidity monitoring,

- Blood glucose measurement,

- Data on the departure, arrival, and outflow of delivered products,

- Fleet, traffic, and mobility management

- Real-time corrosion monitoring in oil and gas plants.

These are just a few examples of areas that are taking advantage of the intelligent data network and exploring its functionalities in their processes.

IoT for maintenance activities in the oil and gas sector

For industries with complex operations, the use of sensors can be applied within plants in order to automate asset integrity management. The plants of these industries have in their structure at least 500,000 assets that need monitoring so that accidents and failures are avoided.

Through the use of IoT sensors on these assets, inspection and maintenance work can be optimized so that labor can be relocated to strategic points. In addition, the use of these sensors allows easy access to information for carrying out activities, since the information collected in the field can be centralized on a single platform.

Future perspectives

A good example to get an idea of the proportion of growth in IoT use in recent years is the growth of access to Smart Cities technology, systems that connect entire cities, managing their electrical networks, supply chain, and public maintenance processes. The healthcare area is also one of the areas in which there is a great expectation of expansion in the use of IoT sensors, today it is already possible to have access to blood glucose meters in real-time, and even to pacemakers equipped with the Internet of Things.

We can conclude that the use of IoT systems is already very common and will soon be a prerequisite for industries. Research carried out by Norton estimated that in 2016 there were already 4.7 billion things connected to the internet and in 2021 this number tends to reach 11.6 billion devices and in 2025 we will have already surpassed the mark of 21 billion IoT devices. It is now up to the industries to adapt to the new scenario and seek to improve the processing capacity of this data generated by the devices, it is also up to the search for new forms of utility and optimization for better performance and results.

Well, now that you know what the Internet of Things is, how it works, and how important it is, how about learning how you can take advantage of its advantages in the industry?

Click here and check out our material that proposes ways to take advantage of IoT technologies in your industry!