In today’s highly competitive business landscape, maximizing efficiency and cost savings is crucial for any organization that wants to succeed. One area where this can be achieved is through effective coating management.

Whether it’s in the manufacturing, construction, or transportation industry, proper coating management can help businesses save time, money, and resources while ensuring high-quality results. From selecting the right coating materials to implementing a robust maintenance program, there are many steps that can be taken to streamline the coating process and minimize waste.

In this article, we’ll explore some of the best practices for coating management and how they can help businesses achieve their efficiency and cost-saving goals. So, if you’re looking to optimize your coating process and boost your bottom line, read on to learn more.

Benefits of Effective Coating Management

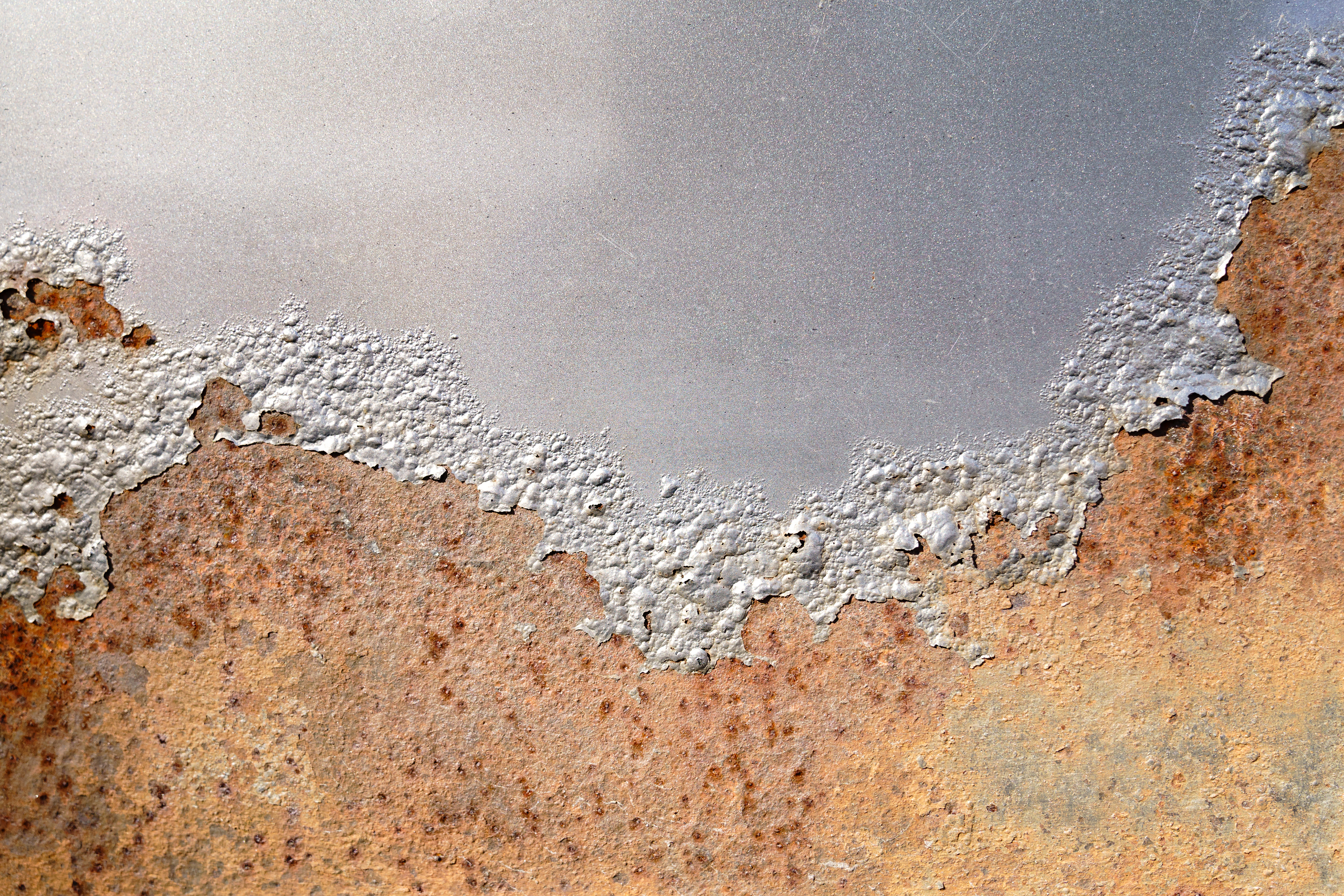

Effective coating management can provide numerous benefits for organizations in various industries. One of the primary benefits is improved quality control. By implementing a robust coating program, businesses can ensure that their products are protected from environmental factors such as corrosion, UV radiation, and abrasion. This can improve the durability and lifespan of products, resulting in fewer returns and replacements.

Another benefit of effective coating management is increased efficiency. By streamlining the coating process, businesses can reduce waste, minimize downtime, and improve overall productivity. This can lead to faster turnaround times, increased throughput, and ultimately, higher profits.

Common Challenges in Coating Management

While effective coating management can provide many benefits, there are also some common challenges that businesses may encounter. One of the biggest challenges is selecting the right coating technology. With so many options available, it can be difficult to determine which coating material is best suited for a particular application. Factors such as durability, adhesion, and chemical resistance must be considered when selecting a coating material.

Another challenge in coating management is maintaining the coating once it has been applied. Coatings can degrade over time due to exposure to the environment or normal wear and tear. Regular inspections and maintenance can help to identify and address any issues before they become a problem.

Best Practices for Coating Management

To overcome the challenges of coating management and achieve optimal results, businesses can implement several best practices. One of the most important is to establish a coating program that is tailored to the specific needs of the organization. This may involve selecting a coating material that is best suited for a particular application, implementing regular inspections and maintenance, and training personnel on proper coating techniques.

Another best practice is to leverage technology and automation to maximize efficiency. This may involve using robotic systems to apply coatings, implementing software to track coating usage and inventory, and using sensors to monitor coating conditions in real time.

Coating Inspection and Maintenance

Regular inspection and maintenance are critical components of effective coating management. Coatings can degrade over time due to exposure to the environment or normal wear and tear. Regular inspections can help to identify and address any issues before they become a problem. Maintenance activities may include cleaning, touch-up, or recoating.

To ensure that coatings are properly maintained, businesses should establish a maintenance program that includes regular inspections and maintenance activities. This program should be tailored to the specific needs of the organization and should be conducted by trained personnel.

Choosing the Right Coating Technology

Choosing the right coating technology is another critical component of effective coating management. There are many different coating materials available, each with its own strengths and weaknesses. Some factors to consider when selecting a coating material include durability, adhesion, and chemical resistance.

To determine which coating material is best suited for a particular application, businesses should conduct a thorough analysis of the environment in which the coating will be used. This may involve assessing factors such as temperature, humidity, and exposure to chemicals or UV radiation.

Maximizing Efficiency with Automation and Technology

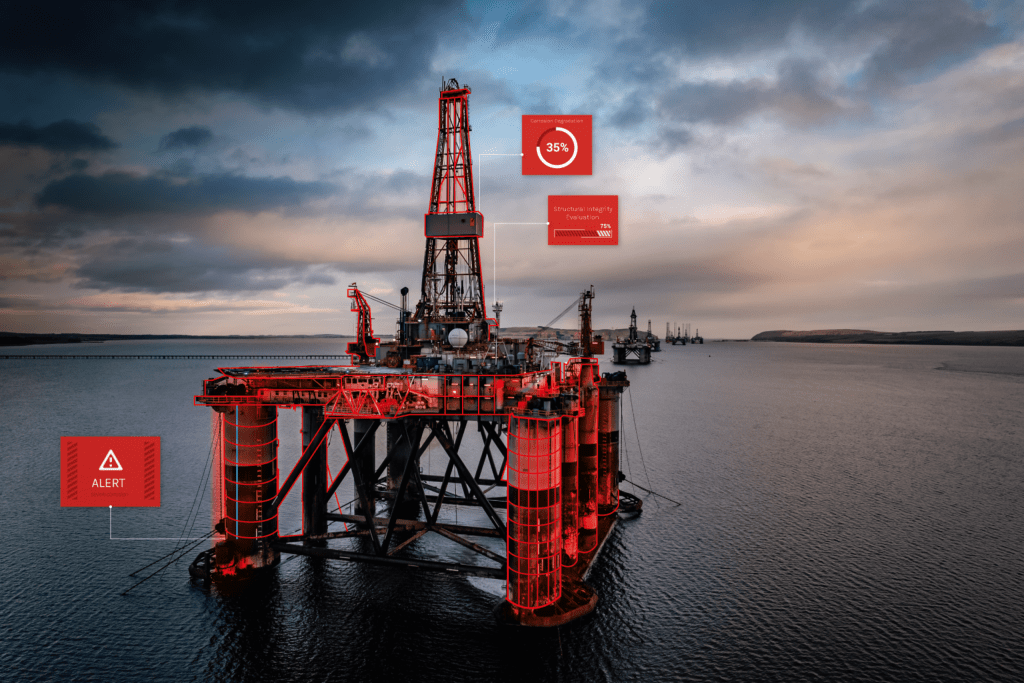

Automation and technology can help businesses to maximize efficiency and reduce costs in the coating process. Digital systems can be used to track coating quality, reducing the need for manual labor and minimizing rework. Additionally, technology can be used to track coating usage and inventory, ensuring that businesses always have the right amount of coating material on hand. Sensors can be used to monitor coating conditions in real-time, alerting personnel to any potential issues before they become a problem.

By leveraging automation and technology, businesses can streamline the coating process, reduce waste, and improve overall productivity.

Cost Savings through Effective Coating Management

Effective coating management can provide significant cost savings for businesses. By implementing a coating program that is tailored to their specific needs, businesses can reduce waste, minimize downtime, and improve overall efficiency. This can lead to faster turnaround times, increased throughput, and ultimately, higher profits.

In addition, effective coating management can help businesses to avoid costly repairs and replacements. By protecting products from environmental factors such as corrosion and UV radiation, businesses can extend the lifespan of their products and reduce the need for costly repairs or replacements.

Case Studies: Digital Fabric Maintenance

Innovation in the Oil & Gas industry has become increasingly attractive. Despite this, McKinsey research indicates that offshore platforms currently operate on average at only 77% of their maximum potential.

In this scenario, in order to speed up the corrosion assessment process and the execution of maintenance plans to assertively manage coating conditions, Vidya developed a project in an operating FPSO. The achieved results in one year are:

- 91 fewer days of People on Board (PoB) for corrosion assessment tasks;

- 59% M/H (Man/Hour) reduction in Maintenance Planning;

- Total savings of more than USD$900,000 in the FPSO.

The contracting company had a pressing need to optimize its annual expenditure of over $2 million on coating management activities. Additionally, the continuous requirement for personnel to be present on board for inspection and problem-solving was leading to increased exposure to risks prevalent in the demanding environments of the Oil and Gas industry. This, in turn, was causing a rise in operational accidents.

Workers walking at oil refinery

To address these challenges, Vidya undertook the development of a Digital Fabric Maintenance project. This project aimed to conduct a virtual corrosion assessment of the FPSO and create corrosion inspection and maintenance plans in significantly less time than usual—less than 70% of the regular timeframe. By contextualizing paint integrity data and integrating field work orders with various ERPs, Vidya effectively managed the customer’s needs.

Fill out the forms to access project details

Conclusion: The Importance of Effective Coating Management for Long-Term Success

Effective coating management is an essential component of long-term success for businesses in various industries. By implementing a coating program that is tailored to their specific needs, businesses can improve quality control, increase efficiency, and reduce costs.

Regular inspections and maintenance, choosing the right coating technology, and leveraging automation and technology can help businesses to overcome the challenges of coating management and achieve optimal results.