Each year new technologies become more present in our lives and routines. This technological advance has caused a strong disruption in the most varied sectors, including the industrial one. From the 4.0 industry technologies such as IoT, Artificial Intelligence (AI), and Big Data, started to become popular and gain space among the most varied industrial processes.

These technologies were some of the factors responsible for the disruption of the sector, which previously performed tasks and activities manually, and which, afterwards, managed to embark these technologies within its processes in search of greater agility, precision, and control over many variables.

Although the use of technology has provided clear advantages over the past few years, there is still a long way to go for these industries.

Industry 4.0 is one of the main technological movements of the last century, it was through it that many processes gained new perspectives of execution based on the use of technology. Understand how this process happened through detailed content, click and access!

INTELLIGENT INDUSTRIES FROM DIGITAL TWIN AND ARTIFICIAL INTELLIGENCE

Industrial processes involve a high degree of complexity in their operations. Industrial facilities are composed of thousands of components arranged in gigantic plants, where every component has its function within the operation and needs to be monitored according to what the operation requires.

In addition to being very extensive, these plants face a great degree of complexity due to their operation. These are disciplines that involve risks for operators and that in the event of failure can lead to catastrophic accidents.

It was thanks to the adoption of mechanisms that make use of artificial intelligence, that year by year these risks have been reduced and these operations become increasingly secure and reach new ways to generate more precision and new forms of optimization.

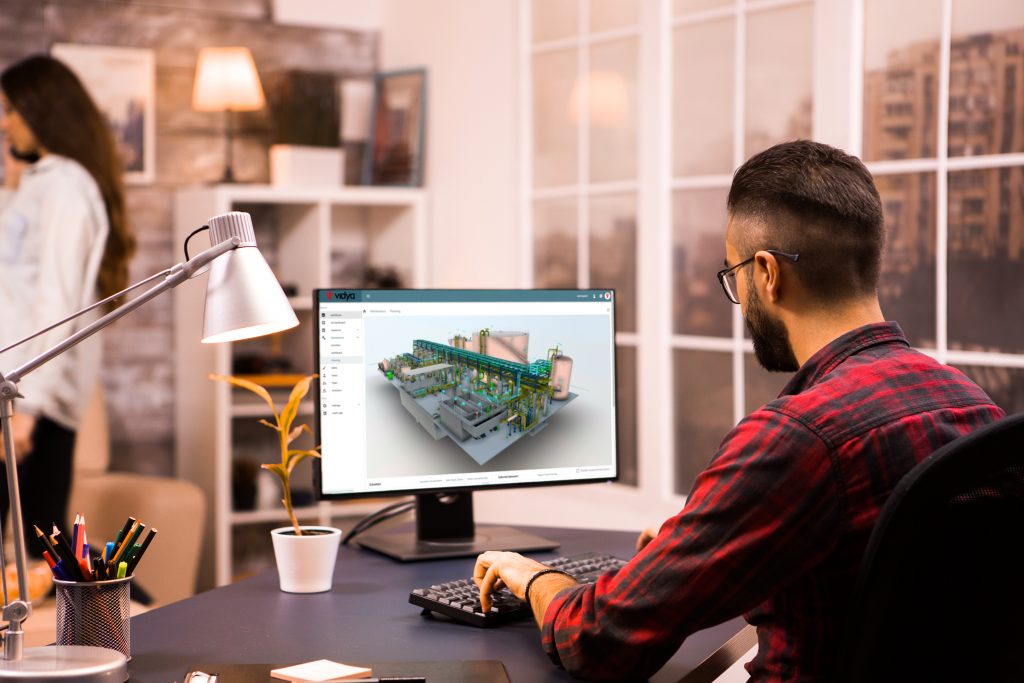

Artificial intelligence was the starting point of the rupture, but soon after, a new technology began to attract the attention of many managers, thanks to the possibilities generated by its use. The Digital Twin consists of a continuous flow of data between a real asset and a virtual twin. This continuous flow of data allows information to be extracted and processed quickly, thus generating an accurate and updated database.

To have an idea of the size of the activity, we have as an example the offshore plants. In addition to being in harsh environments, these large facilities require the integrity of their assets to be healthy, so that they can continue to perform their function without generating risks and loss of productive capacity.

As we mentioned earlier, in a plant where tens of thousands of components must be constantly monitored, it is thanks to Digital Twin, that this activity can be performed without requiring a lot of time from field teams.

Manually, the guarantee of the integrity of these assets would be made through inspection and maintenance activities that could take months to be completely carried out. But it is thanks to tools equipped with artificial intelligence and digital twin that this task can be automated, and manpower can be allocated at strategic points.

The use of technologies has made industries increasingly intelligent and independent of traditional methods. Algorithms and digital twins have added value to operations, generating greater flexibility, agility, and precision in tasks that are crucial for the good performance of an operation.

This disruption should be seen as the next step for industries looking for a future where there is more value to their production chain, generating less risk, and obtaining greater profitability.

Discover the tools that have been used in the search for continuous operation and that each day proves to be true agents of digital transformation.

. Click and access!