With the 4th industrial revolution, the world began to enter a stage known as digital transformation. This period is marked by countless technologies that have gained space among industries, generating new possibilities for optimization and control over operations and processes. Among the various technologies emerging from this period, iiot (Industrial Internet of Things) has become essential for many companies to achieve better results through control over assets, resulting in greater safety for operators and the environment.

When we refer to iiot, we are talking about a segmentation coming from IoT (Internet of things) technology, however, the industrial internet of things has its application focused on industries and their processes.

-

WHAT IS INDUSTRIAL IoT

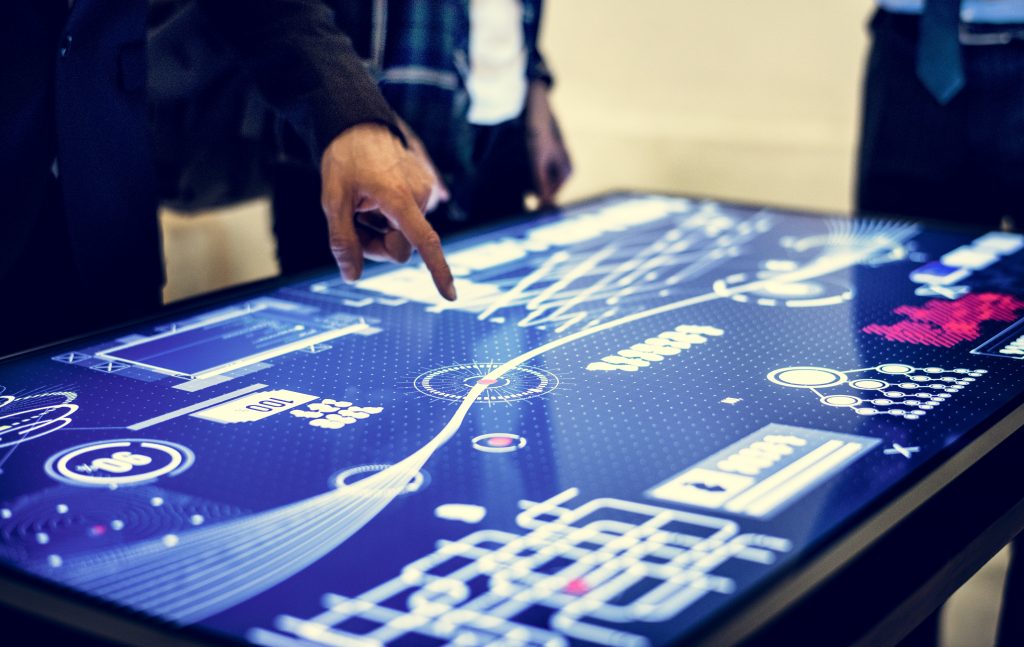

Industrial Internet of Things is an IoT segmentation focused on the specific needs of industries in the most varied segments. Through this technology, machines, equipment, and processes began to share data with each other, in a process known as M2M communication, enabling the control and monitoring of various data, from various disciplines within the operation, thus allowing the responsible operators to gain insights with accurate data, and even quickly identify anomalies that would go unnoticed without the aid of technology.

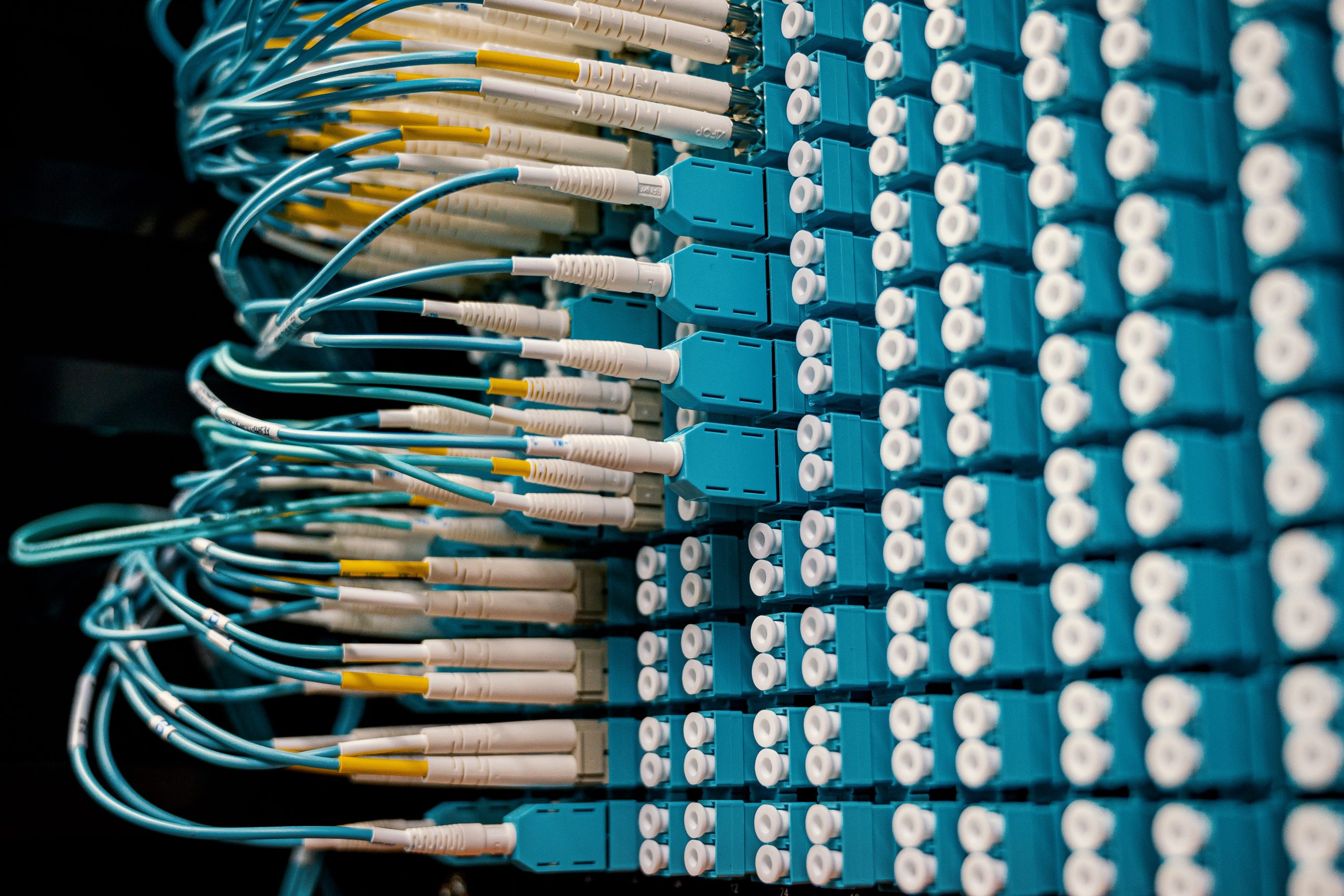

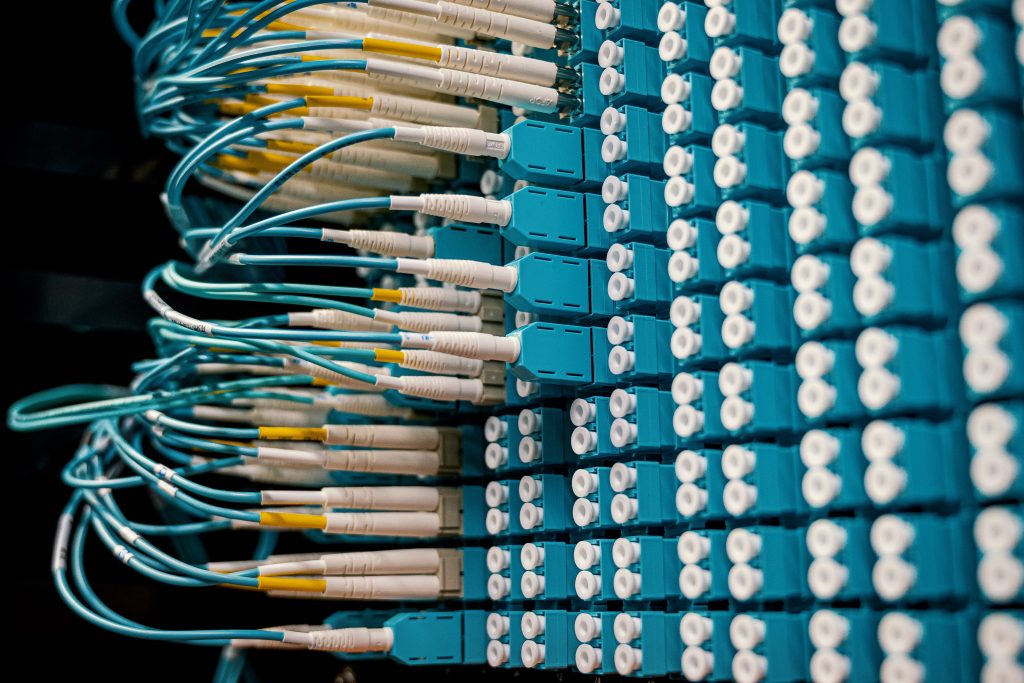

Communication is done through sensors installed on the elements, machines, or components to be monitored. After that, the extracted data are sent to a hub where they are distributed and processed, and thus, can be accessed and analyzed by operators or responsible personnel.

Despite the great advantages that iiot can offer to industrial processes, this technology needs the support of other techniques so that its applications can be better explored within industrial facilities..

The great advance of iiot on the industrial process was possible thanks to the evolution of DCS (distributed control systems), which together with cloud computing enable the automation and optimization of industrial processes.

In addition, the use of Big Data, enabled massive amounts of data to be stored and processed in the cloud, making the flow of information more dynamic, since from its use there is no longer a dependence on physical devices for the storage of data.

Within an industrial plant there are gigantic amounts of data that are processed and examined using techniques that make use of Big Data, however, there is also the decentralization of that information through computational architectures called Edge Computing, which allow the information to be closer to where they are requested, making data access faster.

iiot can then be seen as the basic technology, which requires technologies such as AI (Artificial Intelligence), Big Data, CDS, and Edge Computing so that its application is viable to the various requirements and variables that industrial processes require.

There are several computational techniques that have brought new possibilities for applications to industries. Understand what are the main computational concepts and techniques that make use of Artificial Intelligence that the industry has used to its advantage in a content that will revolutionize your view on this vast technological field. Click to learn more!

-

IIoT for the oil and gas industries

The oil and gas industries are great examples of complex and delicate operations, with many variables that must be considered for any decision making. And it is in this type of scenario that the use of iiot becomes an important differential that can contribute to the technological revolution coming from industry 4.0. These industries have operations with a high degree of complexity, which involves great risks to operators and the environment in the event of failure, thus, the monitoring of assets on a large scale, becomes a fundamental point for the smooth operation of the operation as a whole.

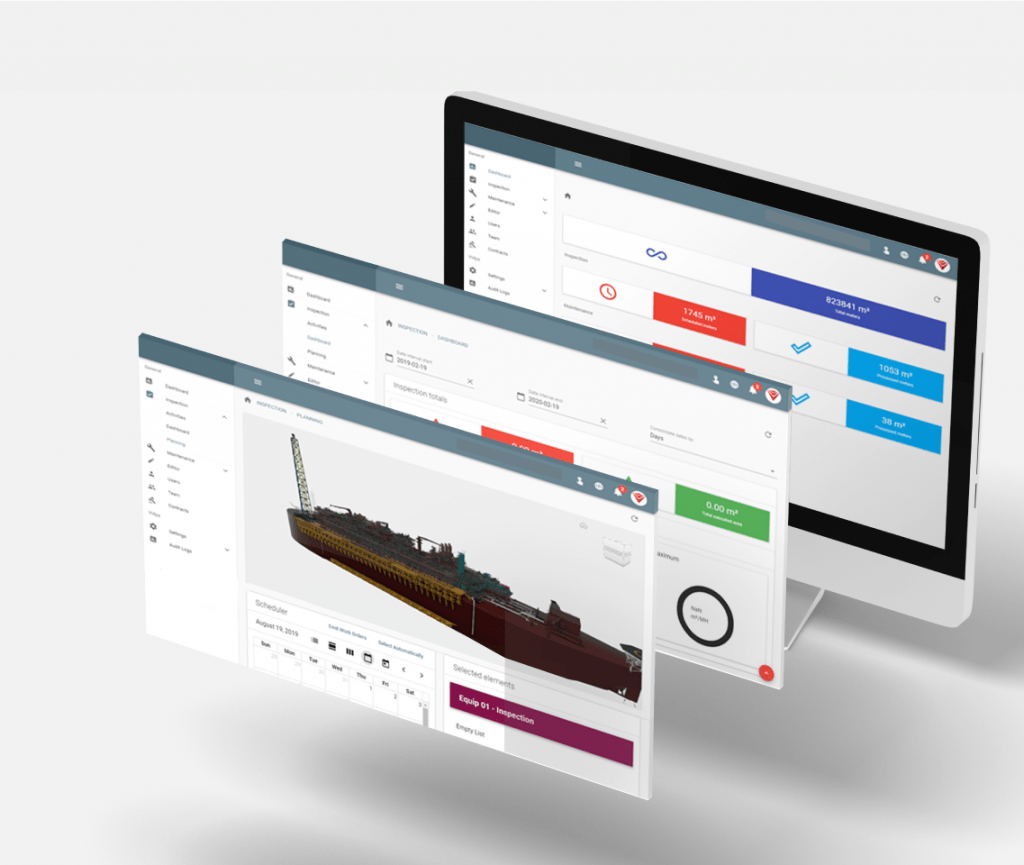

Thanks to the use of iiot in line with software and platforms geared to the specific needs of each operation, the oil and gas industry has the possibility to obtain accurate data on the integrity of its assets, and the progress of its operation.

For this industry, tasks involving maintenance and inspection, which are often major challenges for this type of operation given the size and complexity of the facilities, can be enhanced through iiot technology. Through the sensors, it is possible to identify gas leaks in areas of difficult access, or even to identify areas of overload in real-time, of piping systems with hundreds of kilometers.

Aligned with specific software, there are several possibilities that iiot technology can offer in risk management control, asset integrity control, and field team management.

Given the relevance of the industrial internet of things and the high expectation of implementation by industries, it is estimated that by the year 2030, technology should bring at least 14.2 trillion dollars to the world economy, according to the article by Conrad Hofmeyr on the topic, published by Forbes magazine.

The diverse functionalities and applications of this technology significantly mark the period of digital transformation experienced by industries in recent years and attract the eyes of many industries that aim at the continuous search for optimization and greater performance in their operations through a continuous and accurate flow of data extracted.

It is expected that industries will gradually adapt to digital transformation technologies and that their processes will no longer be done manually and will become automated and digitized. Undoubtedly, the Industrial internet of Things has shown the potential to be one of the main responsible for this great revolution within the industrial scenario. It is now up to companies to decide to implement this technology that has created so many new possibilities since its emergence after the 4th industrial revolution.

Now that you are familiar with the applications of iiot in industrial processes, how about knowing in detail platforms that make use of this technology and enable the implementation of an accurate data network on the integrity of assets, generated optimization of field teams, and greater control over the operation. Click and meet Vidya Software.