In the ever-evolving landscape of the Oil and Gas sector, Vidya Technology stands out as a lighthouse of innovation, leading the charge in digital transformation. Over the past decade, Vidya has not only provided generic solutions but has tackled the intricate challenges faced by the industry, specifically within the realm of asset integrity management. What sets Vidya apart is its unwavering commitment to understanding the nuanced needs of its clients, enabling the company to craft solutions that are not just complex algorithms but fast, scalable, and practical applications that can be implemented, yielding tangible results in a matter of months.

Addressing the Challenges

Within the domain of asset integrity management, safety is the primary concern. Vidya recognizes this and has made it a core objective to ensure that every operation prioritizes safety above all else.

In addition to safety concerns, the effectiveness of integrity management has been a persistent challenge. Vidya, leveraging the power of Artificial Intelligence, has made significant advancements in this area. Through automation, Vidya’s solutions can now track anomalies with a staggering 256% increase in accuracy compared to visual inspection methods.

This level of precision not only ensures the smooth operation of facilities but also provides confidence in the integrity of the assets.

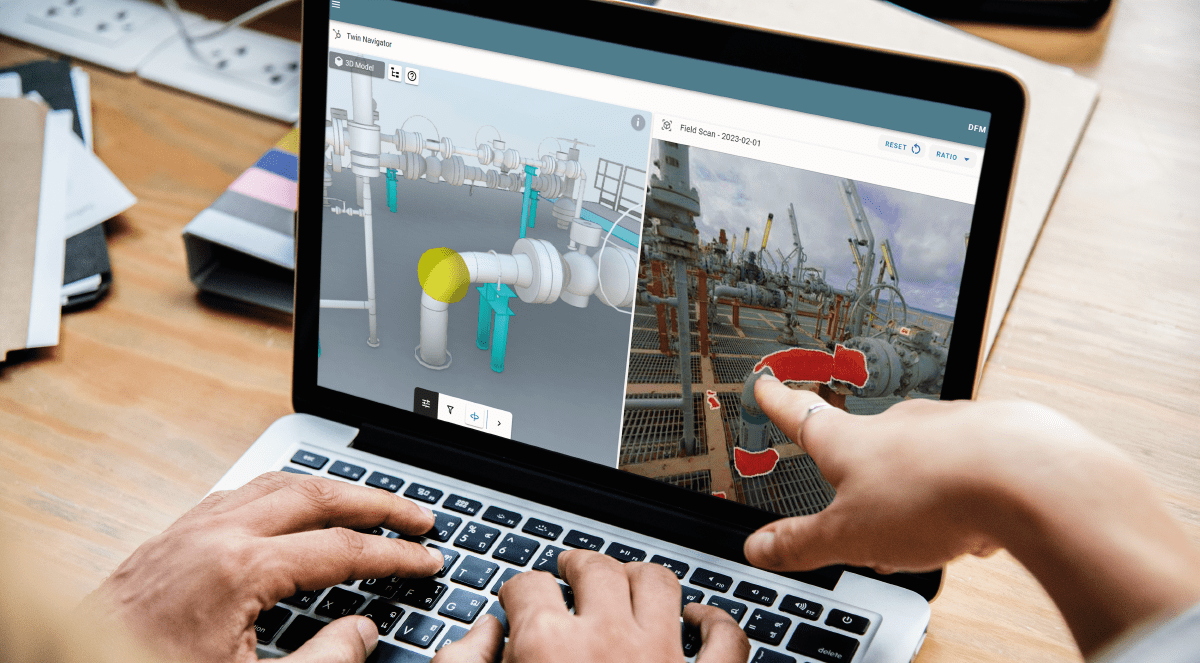

Bridging the Gap with Vidya VSP

Vidya VSP (Vidya System Platform) is the embodiment of Vidya’s commitment to excellence. It serves as the bridge between integrity data and management systems, presenting crucial information in a visually intuitive manner. Unlike mere reporting tools, Vidya VSP empowers users with actionable insights, fostering informed decision-making and driving operational performance to new heights.

Applications in Action

Digital Fabric Maintenance:

Corrosion, a pervasive issue in the Oil and Gas industry, poses a significant financial burden. Vidya’s Digital Fabric Maintenance application tackles this challenge by streamlining corrosion assessment. Through the power of Artificial Intelligence, it enables automated corrosion monitoring, offering real-time insights that allow industries to optimize their resources effectively.

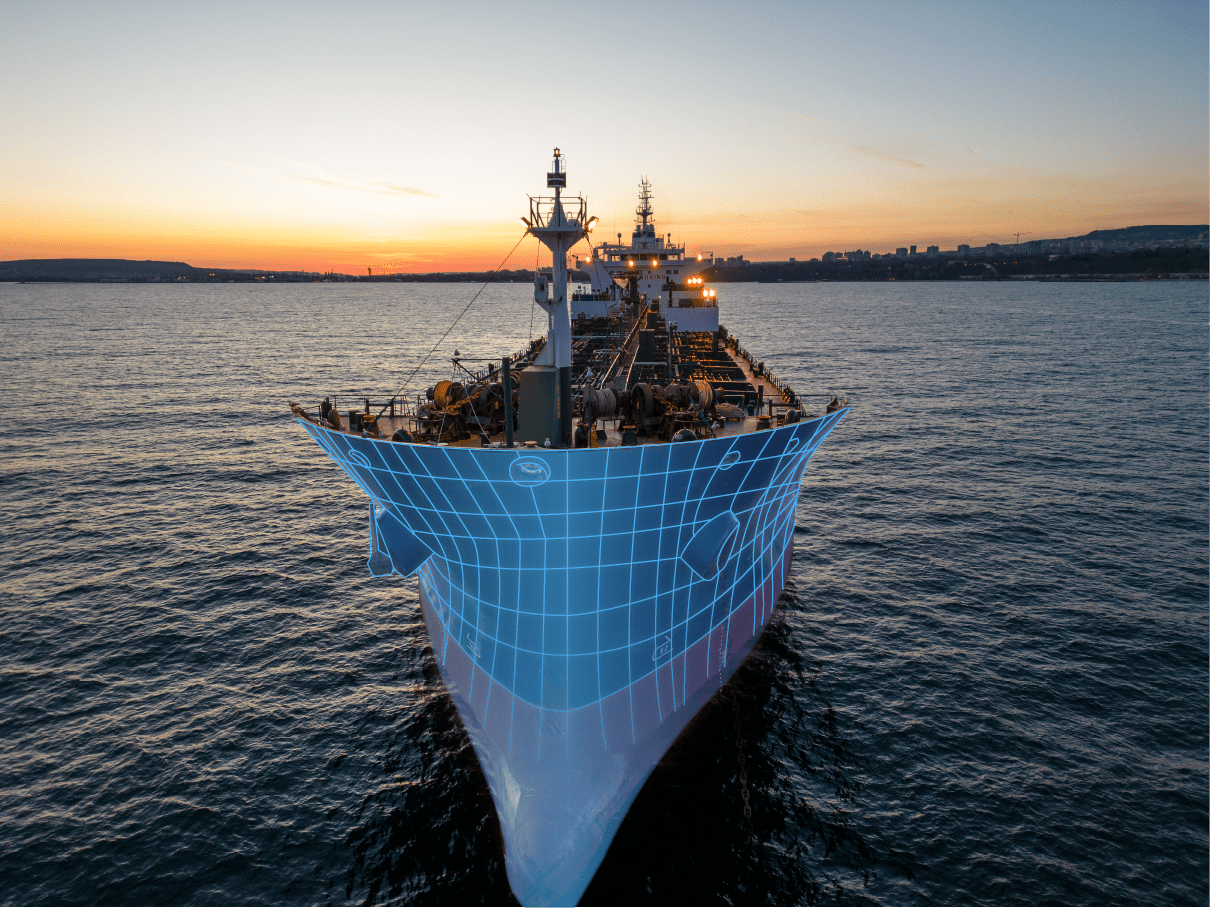

Digital Hull Tracking:

Operational reliability is paramount in marine vessels, and Vidya’s Digital Hull Tracking application ensures that. By leveraging a 90% accurate Artificial Intelligence, it identifies issues such as corrosion, cracks, discontinuities, and welding problems. This proactive approach to mapping and monitoring guarantees accurate information for in-depth engineering analysis, minimizing maintenance costs and downtime.

Naval Digital Tracking:

Traditional inspection methods can be unreliable and often lead to costly errors. Vidya’s Naval Digital Tracking application revolutionizes the process by integrating historical contextualized integrity data into a 3D model. This innovative approach provides engineers with essential outcomes for analytical work, inspection blueprints, and compliance evaluations, ensuring the extended lifespan of vessels.

![]()

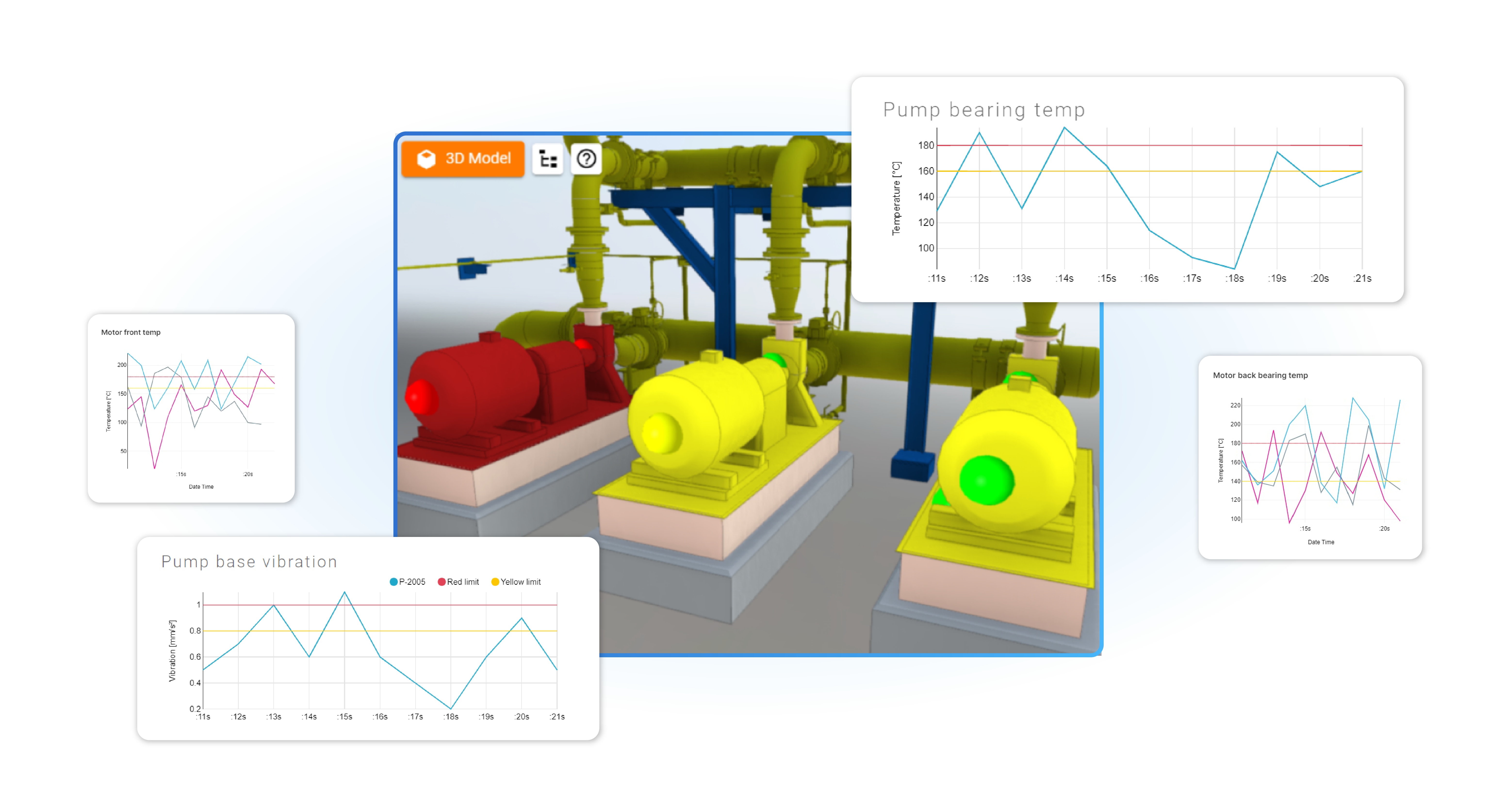

Digital Equipment Performance:

Predictive maintenance is a cornerstone of operational efficiency, and Vidya’s Digital Equipment Performance application takes it to the next level. Through meticulous data engineering supported by Artificial Intelligence, it enables rapid mapping, analysis, and correlation of vast volumes of data. As a result, precise predictive analysis, reduced downtime, and seamless integration with ERPs and CMMSs, ensure optimal performance of critical equipment.

Transforming the Future

In a landscape where digital transformation is not just a choice but a necessity, Vidya Technology stands ahead. Through innovative solutions, Vidya not only addresses the challenges faced by the Oil and Gas sector but propels it into a future where efficiency, safety, and reliability go hand in hand. As industries continue to grapple with the complexities of asset integrity management, Vidya’s commitment to excellence and cutting-edge technology serves as a guide in the way of a digitally transformed future.