Your Hull Integrity deserves more than spreadsheets

By combining data engineering, 3D modeling, and data contextualization, the Naval Digital Tracking converts raw inspection data into actionable insights. Centralize thickness measurements, historical data and anomalies on one platform. Empower your team with predictive analytics for data-driven decisions.

Our company is trusted by:

Our company is trusted by:

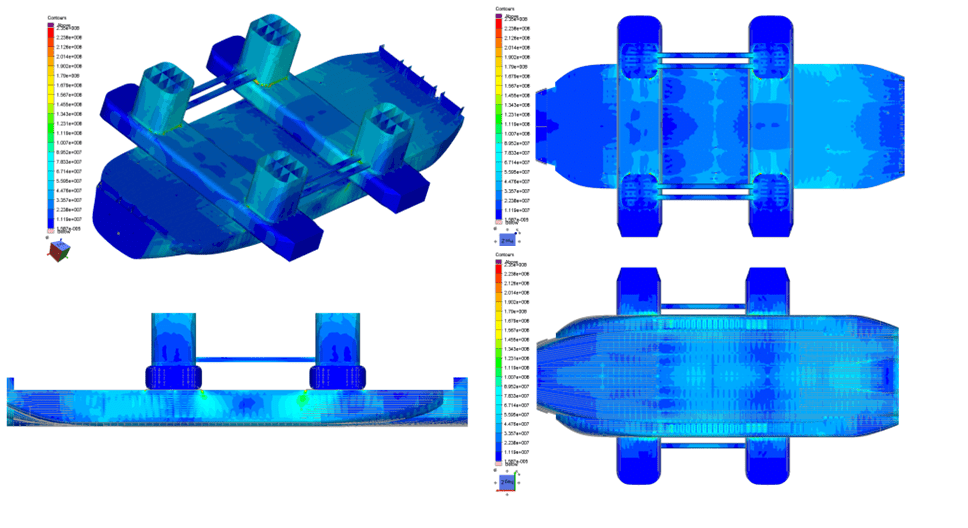

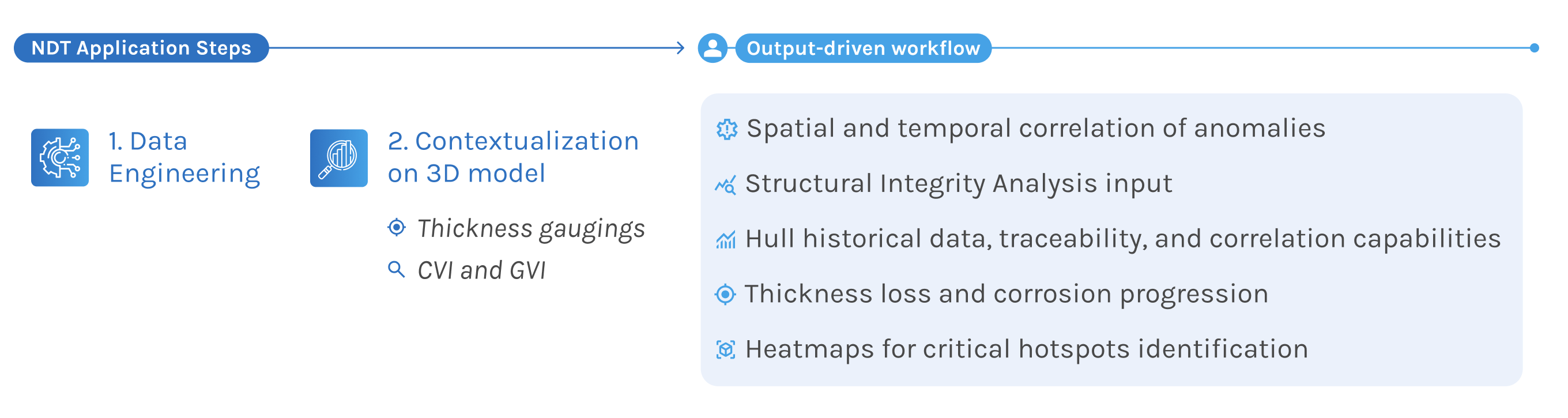

How does the Naval Digital Tracking work?

By employing advanced data engineering, automatic data extraction and contextualization of thickness gauges to process and analyze data within a 3D environment, we provide a web platform for visualizing and managing historical and projected hull integrity.

Understand your hull integrity condition through measurement points and heatmaps. This approach supports naval engineers and classification societies for structural integrity assessments through predictive analytics, traceability of inspection records, and integration of integrity evaluation processes.

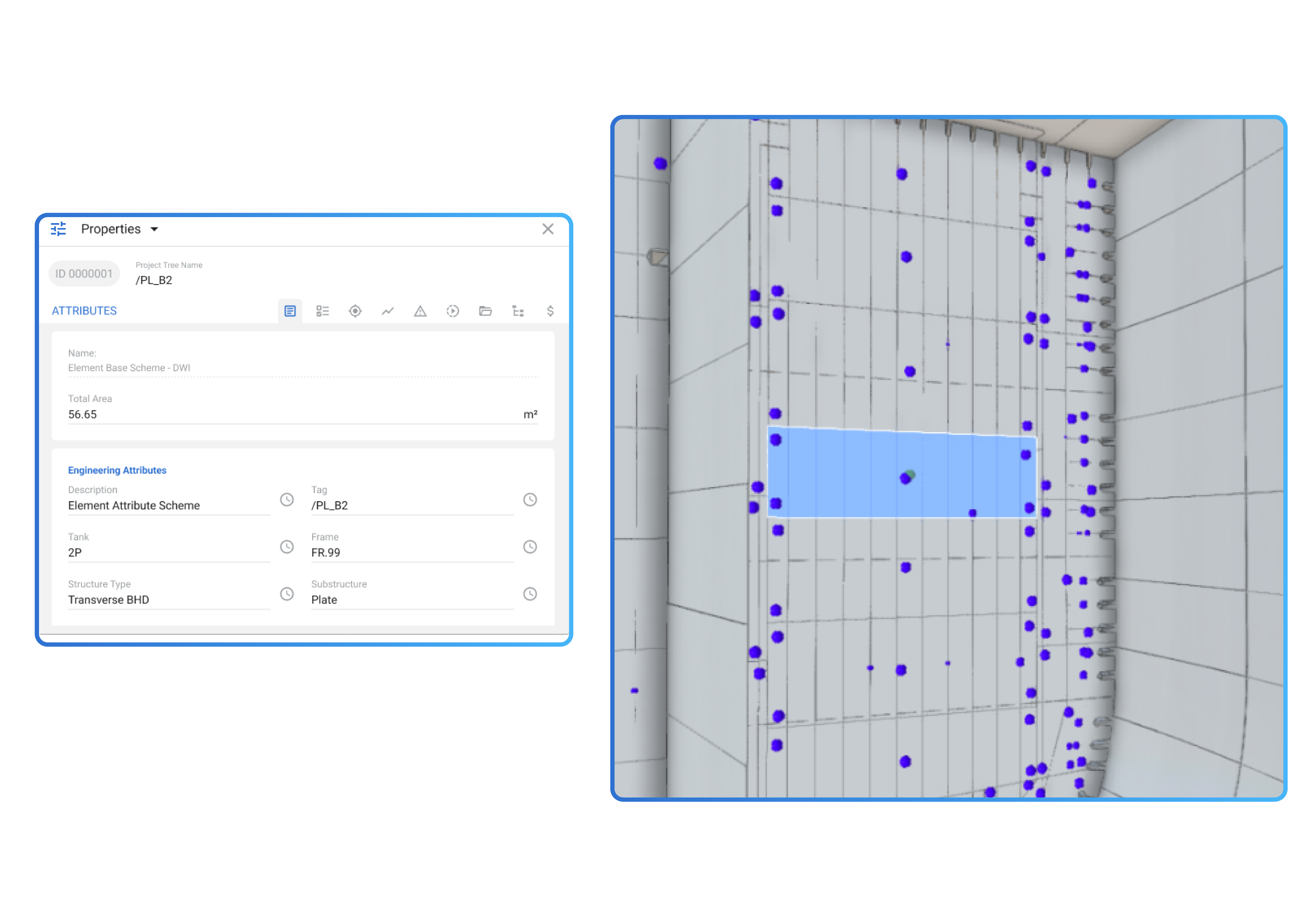

3D Setup: Visual Insights at your fingertips

Data Contextualization: Transforming data into understanding

Enabling Accurate Naval Support through data contextualization.

This approach facilitates identification of corrosion patterns, defect progression, and prioritization of maintenance activities.

Systematic Risk Ranking: Naval Heatmap Visualization

Mobile: Made for Industry

See Naval Digital Tracking in Action. Schedule a Demo and Experience the benefits

Contact us to learn how this solution fits your operation

Beyond a digital solution, we deliver tangible benefits for you. By scheduling a meeting, we will:

- Understand your challenges: We’ll listen closely to your top concerns around tank integrity management and the current methods you’re using.

- Showcase our Naval Digital Tracking application: Discover how our technology streamlines hull integrity management, saving you valuable time and resources.

- Demonstrate real-world results: See firsthand the impact we’ve achieved for other companies in reducing similar issues.

- Craft a tailored plan: We’ll work together to identify how our solution can specifically improve your integrity management and monitoring processes.

- Propose a pilot: Lets target a specific area of your operation to address fabric maintenance challenges. Experience the results and scale up for total transformation.