Balancing Maintenance and Production Demands for Maximizing Efficiency in Steel Industry

Intro In any manufacturing or production facility, balancing maintenance and production demands is crucial for ensuring that the operation runs safely and efficiently. While it's important to focus on meeting production targets and fulfilling orders, it's equally important to prioritize maintenance tasks to avoid equipment breakdowns and production delays. In this blog, we'll discuss the importance of balancing maintenance and production demands and provide best practices for maximizing efficiency. Understanding Maintenance and Production Demands The steel industry requires significant investments in capital equipment and machinery, which must operate continuously and efficiently to meet production targets. Maintenance demands in the [...]

Overcoming the Challenges of Inspecting Remote and Harsh Environments

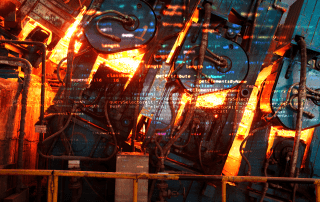

Intro The steel industry, a critical sector that underpins modern society, plays a vital role in numerous areas such as construction, transportation, manufacturing, and energy. This industry is responsible for manufacturing a wide range of steel products, including sheets, coils, bars, and tubes, among others, which are integral to various applications. The steel production process encompasses several stages, from raw material extraction to ironmaking, steelmaking, and casting, each requiring precise execution and quality control. However, the steel industry faces a multitude of operational challenges. Firstly, it must strive to maintain high levels of productivity while simultaneously minimizing its environmental footprint. [...]

Main challenges regarding Steel Industries Operation and Maintenance

Steel industries, one of the oldest and most significant sectors in the global market, has faced long-standing challenges that stem from the inherent rigidity of its processes and the often harsh operating environments it encounters. Despite these complexities, the imperative for innovation within this sector remains essential. In this post, we delve into the primary challenges that the steel industry confronts, with the aim of shedding light on the critical areas that require innovation and process optimization. The historical significance and widespread influence of the steel industry cannot be overstated. Its products form the backbone of countless sectors, ranging [...]

Benefits of Digital Twin in the Steel Industry

The application of new technologies in the most diverse industries has shown very positive results when it comes to greater control of the operation and improvement in results. In the case of steel industries, this scenario is intensified. Located in harsh environments and operated in critical situations, the digitization of processes and improved data collection and analysis has allowed these industries to reduce unplanned downtime, improve worker safety, and cut operational costs. As the main protagonist of this digital transformation, there is the Digital Twin. Here is a more detailed explanation of how Vidya's application of this technology can [...]

3 ways to optimize Steel Industry operation and maintenance results

Despite being an essential sector for almost every type of operation, from the supply of raw materials to the manufacturing of final products, the steel industry is not immune to various economic problems and challenges in optimizing its operation. Aiming to strengthen itself after the peak of the coronavirus pandemic, several opportunities in process optimization and maintenance in this sector have emerged. But what can the managers of these industries focus on to minimize the after-effects of years of declining results? Read the article below and find out what are the best ways to optimize the operation and maintenance [...]