Asset Integrity Management, also represented by AIM, is the ability of an industrial asset to perform its function precisely and efficiently, with optimal lifetime and proper safety.

Asset management is necessary from the design stage to the end of an asset’s useful life. All stages of the process must be taken into account so that there is efficient management without major risks to the environment, people, and the industrial installation of which they are a part.

In this blog, we will explore the major challenges of Asset Integrity Management and how the Oil and Gas industry is facing the digitalization of this important discipline.

Signs of unoptimized asset integrity management

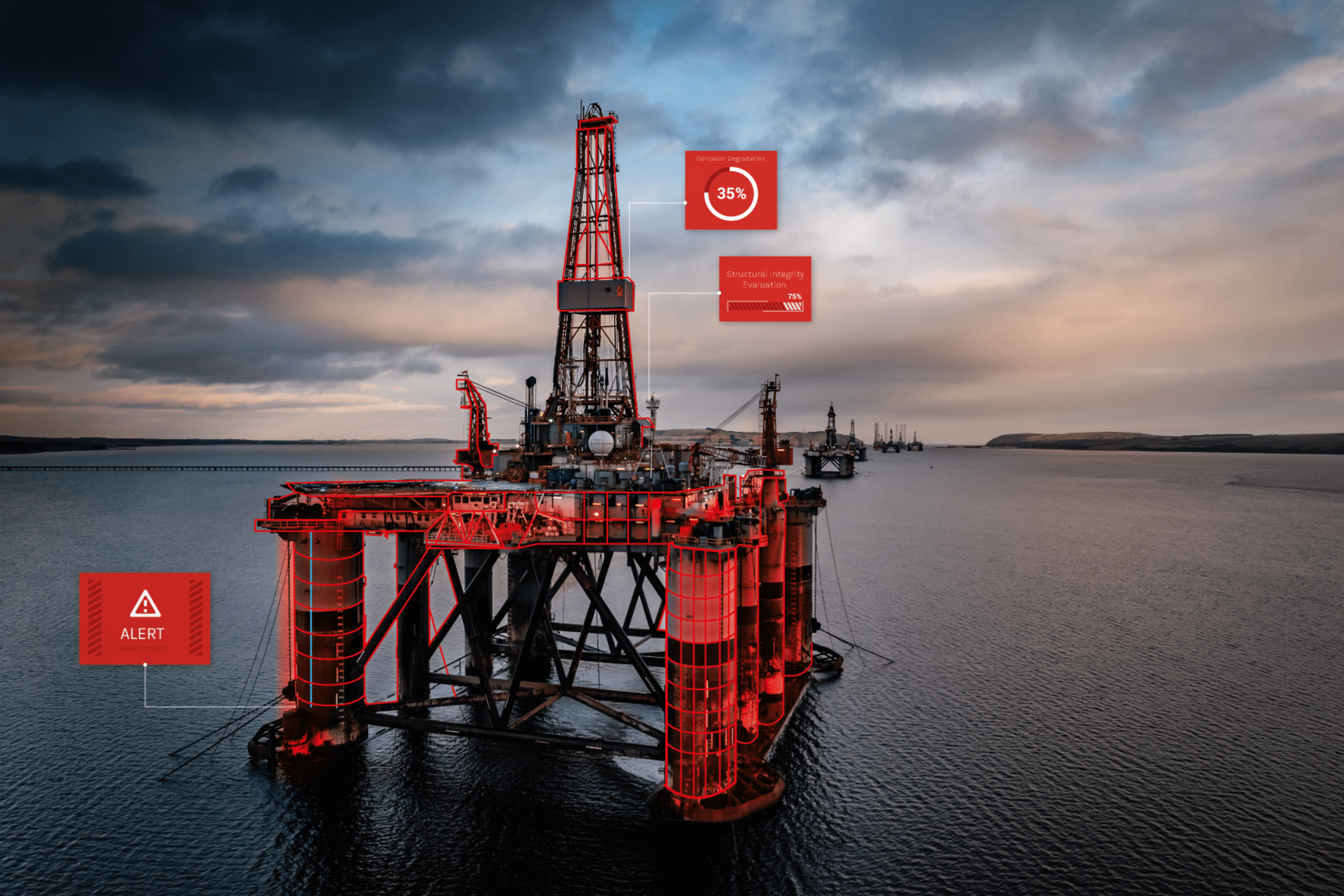

The management of industrial assets integrity is of major necessity within complex industrial plants, especially those of Oil and Gas, Offshores, Petrochemicals, and Mining. Many of these plants have a very high degree of complexity, making the detection of minimal failures a task that besides demanding a lot of labor time, may not always be accurate and lead to catastrophic failures.

Meanwhile, new approaches to Asset Integrity Management have arisen so the safety of the process could be preserved and new opportunities leveraged.

Imagine that in a large industrial plant, minimal failures are not noticed and maintenance plans do not give them the necessary attention, either due to a process bottleneck or due to inefficient maintenance management.

It may also be the case that the sector responsible for maintenance is not aware of the necessary budget required for the assets to be preserved or replaced in optimal opportunity.

Those are early signs of unoptimized integrity management. As consequence assets start to fail constantly, minor failures start to exist within the plant and production has to be subject to numerous unplanned downtime. Soon, employees will be exposed to risk and the imminence of a big-scale failure becomes imminent.

This is the kind of scenario that no company wants to go through, and that efficient Asset Integrity Management seeks on preventing.

The early identification and prevention of this kind of failure have become fundamental aspects within industrial plants not only due to safety standards but also because effective AIM has a direct impact on the economics of an operation.

The problems faced by the industry

One of the biggest challenges in the industry when it comes to Asset Integrity Management is to achieve a balance between performance, risk, and cost. The harmony between these three factors will reflect in an optimized management of investment, time, and resources allocated so that the longevity of the components of a system is preserved.

Access to understand how Vidya is adressing asset integrity challenges

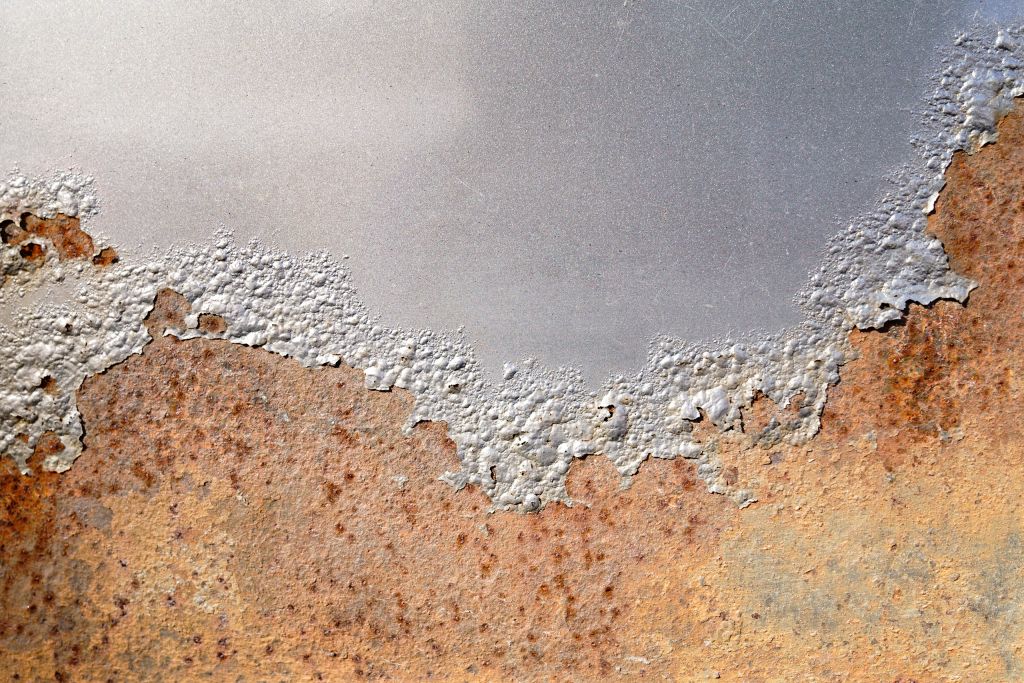

- The main point of attention to inspection teams is to comprehend if the assets are performing according to the expected without presenting wear, cracks, or corrosion that could lead to unplanned process downtime. This task demands tools able to detect and track asset performance.

- Another factor of extreme importance when it comes to the effective management of industrial assets is to guarantee maximum safety within an industrial facility. For this to be possible, the maintenance and inspection processes must work precisely. It is necessary to fully understand the source of failure mechanisms.

The adequacy of the above processes will guarantee the optimal lifetime of assets within the installation, resulting in the continuity of an extraction and production line with the minimum possible downtime and lost performance.

Click and understand the key concepts of Asset Performance Management

Leveraging enhanced asset integrity management in Oil and Gas industries

Asset Integrity management plays a crucial role in ensuring the optimal operation of production systems, encompassing a range of intricate practices. The effective functioning of these practices heavily relies on seamless communication and integration between the various systems involved. Additionally, in the era of advancing digital technology, it becomes increasingly vital to address concerns surrounding trusted and contextualized datasets.

In today’s digital age, the emergence of advanced technologies presents both opportunities and challenges for Asset Integrity management. The adoption of digital solutions, such as the Digital Twin, Artificial Intelligence (AI), and Data Analytics, has the potential to revolutionize the way asset integrity is managed. These technologies can enhance real-time monitoring, predictive maintenance, and risk assessment capabilities, ultimately improving asset performance and minimizing downtime.

In an interview with Forbes magazine, Dean Arnison, global product leader-subsea of production systems, and services at BHGE, explains how companies in the Oil and Gas sector are embarking on this digital journey. According to Arnison, industries are looking for increased productivity and reduced costs, with new business models, strong partnerships, and integrated service models. Arnison believes that most oil and gas companies are on a similar journey, looking at how to reduce basic costs while exploring ways in which digital can be leveraged to optimize asset production through a better understanding of failure and inefficiencies.

In another report by Business Wire, the estimated growth value of the Asset Integrity market is US $ 15.4 billion until 2025. These trends show us how the market is positioning itself and adopting Asset Integrity Management strategies well within its operations.

The adoption of digital processes for managing industrial assets represents a significant technological revolution with the potential to yield cost reductions, minimize environmental impacts, and enhance worker safety within plants.

If you want to understand how Vidya is helping the integrity management of industries fill out the forms below

Conclusion

It is evident that the implementation of Asset Integrity Management (AIM) systems has become an indispensable requirement for industries striving to maintain seamless production operations while achieving optimal productivity, complying with regulations, and ensuring the utmost safety for their structures and personnel. addition to mitigating risks, AIM systems also contribute to enhancing productivity performance. By implementing robust strategies for asset management, organizations can optimize maintenance schedules, streamline workflows, and maximize operational efficiency. These systems allow for data-driven decision-making, enabling timely interventions, resource optimization, and improved asset performance. As a result, industries can achieve higher productivity levels and capitalize on their assets’ full potential.