The digital transformation has proven to be a great tool for industries in recent years. It is thanks to its innovative technologies that many industries have the possibility to automate and digitize their processes and operations.

However, there is still a big gap in the industrial sector for the implementation of these technologies.

Discover all the aspects, applications and innovations resulting from digital transformation through content that we have prepared detailing this concept. Click and access!

With access to IoT, Digital Twin and Artificial Intelligence (AI) technologies, many activities have been transformed and digitized through tools that have been using these technologies as a way to achieve better results through greater control over the operation, aiming to extinguish line interruptions production, possible failures and generate the best team management in the field.

Despite the great advantages provided by digital transformation, there is still a slow pace in adapting industries to this new business model. The complexity of industrial processes is one of the obstacles that the new digital age has in its path.

HOW DIGITAL TRANSFORMATION HAS BEEN APPLIED IN THE INDUSTRIAL SECTOR

Digital transformation is already a reality in our daily lives. We easily find IoT devices becoming part of basic everyday equipment and being increasingly commercialized on the market, smart devices, and even digital twins, are technologies that have become increasingly present in our lives.

However, when we analyze how these technologies have been adapted to industrial processes and operations, it is noted that many industries are still going through a transition process between manual and digital.

One of the main examples is the oil and gas sector, in which there are many variables that are difficult to control that must be considered, analyzed, and understood, for any decision making or execution of activities.

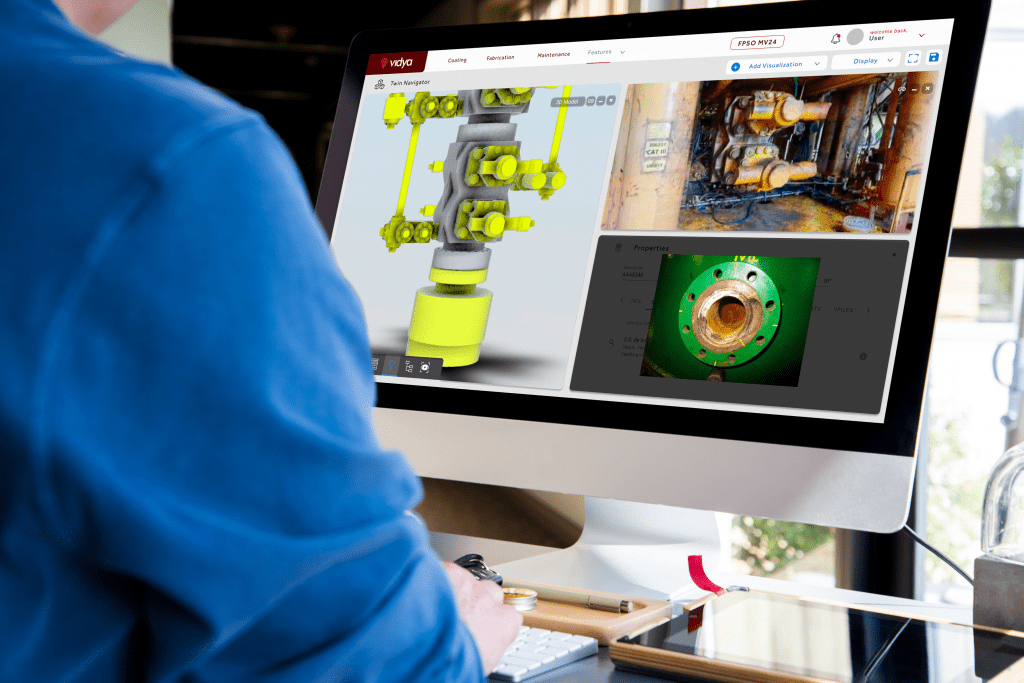

And it is in the midst of this complexity of the sector that many industries have opted for specific software that assist in the application of technologies such as IoT, IA, and Digital Twin within the processes.

From these software, industries now have access to tools capable of performing specific functions to their operation with technologies that are generating a strong disruption with the current operations models.

It is this software that has given these large industries, which are considered complex, to reach new heights with the help of technology.

For the oil and gas sector, the use of this technology is reflected in total control over the operation. It is through Digital Twin that the operation is controlled, it is through IoT sensors that data is extracted, and with the aid of AI algorithms, it is possible to have the prediction, simulation, and in-depth analysis of the countless variables that make of the complex operation.

Having a tool that brings together all these technologies and information in a centralized way means having the necessary means at hand to move towards innovation. Achieving the best results with sustainability, flexibility, and, above all, security.

Digital transformation is based on the ability to adapt and resilience, it is disruption and reinvention. It is the ability to evolve safely, reducing risks, valuing the production chain.

Understanding digital transformation not as an advantage, but as a necessity, maybe the great differential of the coming years. In an increasingly digital age, it is the capacity for adaptation, flexibility, and innovation that will tell which industries are ahead of their time.

Learn more about the software that has been helping the transition to the new digital age within complex industrial operations. Click and access!