What Really Slows Turnover Cycles in Industrial Assets

Turnover rarely extends because tasks are technically difficult. It extends because teams do not fully trust the information they are handed. Too often, turnover is treated as a short, procedural, and largely administrative step: a final checkbox before responsibility shifts to the next stakeholder. Yet, in practice, they are some of the most fragile moments in an asset’s lifecycle. Decisions made under time pressure, with incomplete visibility, determine whether an asset returns to service with confidence or with unresolved uncertainty quietly embedded into operations. So why do turnover cycles so often stretch beyond plan, even when execution is complete, and [...]

As 3 etapas da gestão da integridade dos ativos no setor energético

A Gestão da Integridade de Ativos (AIM) é um domínio fundamental para indústrias de processos de grande porte. Trata-se de uma disciplina voltada a maximizar a eficiência e a confiabilidade de plantas industriais, envolvendo múltiplas metodologias, sistemas, profissionais e atividades. Este blog explora como líderes industriais estruturam a AIM, apresentando um passo a passo para a implementação de um programa robusto. No entanto, antes de compreender o estado atual da AIM, é importante entender: como essa disciplina evoluiu até se tornar uma área tão complexa e específica? Entendendo a Gestão da Integridade de Ativos A Gestão da Integridade [...]

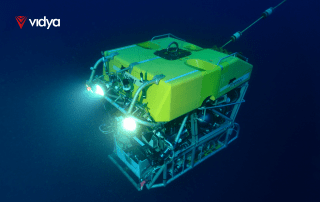

Subsea Integrity and Technology: Managing Wells in the Harshest Environment on Earth

We know a lot about planets that are millions of light-years away, but when it comes to the basement of our own house, it’s a different story. The bottom of the sea remains one of the least explored environments on Earth. While we invest enormous curiosity in what lies beyond our atmosphere, the vast underwater world, right beneath our feet, receives only a fraction of the attention. And yet, it is there, in this silent, dark, and pressurized frontier, that some of our most complex engineering feats take place. Hidden from sight, thousands of meters below the surface, critical assets [...]

Beyond corrosion detection: How is Vidya’s System being used?

Corrosion. AI. Digital Twin. You already know that the Vidya System Platform (VSP) stands out in these disciplines. But what started as a corrosion-focused platform quickly became a versatile system for understanding and managing complex industrial realities. Its evolution reflects how technology and user demands continue to shape one another. But what else is possible to do within Vidya’s solution? Well, we asked our clients how they are using the VSP. Janaina Albino and Stefany Batista, Delivery and Customer Success Team From detecting corrosion to operating with ease Born as a corrosion-targeted solution, the scope and capabilities [...]

Integridad de FPSOs 101: retos, estrategias y el rumbo a seguir

Los FPSO (Floating Production, Storage, and Offloading units, por sus siglas en inglés) se encuentran en la intersección entre la ingeniería extrema y la estrategia económica a largo plazo. Su presencia en aguas marítimas profundas viabiliza la extracción de gas y petróleo en lugares donde la infraestructura fija sería inviable. En estos activos industriales, cada componente de la embarcación está continuamente expuesto a condiciones severas de las profundidades del mar, fatiga estructural, cargas variables y esfuerzos mecánicos. Sumado a ello, la corrosión ataca lentamente los cascos, risers y equipos de topside. Los movimientos repetitivos de las olas y las tensiones [...]

What Is Structural Integrity Management and Why Does It Matter

Structural Integrity Management (SIM) refers to the systematic process of ensuring that a physical asset, whether a pipeline, offshore platform, storage tank, bridge, or structural frame, retains sufficient strength, stiffness, and safety margins over its intended life, under both normal and extreme loads, environmental degradation, and operational changes. It is not just a one-off check; instead, Structural Integrity Management spans all phases of an asset’s life: design, fabrication, construction, commissioning, operation, and decommissioning. In essence, structural integrity combines inspection, monitoring, modeling, assessment, and maintenance planning to detect, evaluate, mitigate, or prevent structural damage, fatigue, corrosion, defects, or other forms of [...]

Beyond Compliance: Integrating Process Safety and Asset Integrity in Offshore Oil & Gas

The evolution of safety in offshore oil and gas operations is closely tied to global advancements in safety culture, legislation, and best practices. A major turning point in offshore safety history was the shift from prescriptive, equipment-focused laws to performance-based and self-regulatory frameworks that emphasize systemic risk management, asset integrity, and human factors. From Frameworks to Function: Why Process Safety Became Central As offshore operations grew in complexity, the limitations of traditional safety models became clear. Regulatory evolution set the stage, but it was the industry's increasing awareness of systemic vulnerabilities that pushed for a deeper, more technical [...]

5 Steps to Strengthen Your Static Equipment Compliance Strategy

In large-process industries, static equipment such as pressure vessels, piping, and storage tanks represents the majority of operational machinery. While these assets may not move or rotate like pumps or turbines, their failure can be equally catastrophic, leading to safety incidents, production losses, and regulatory penalties. Understanding the nature and function of these assets is the first step toward building a robust and auditable integrity management framework. And, given the scale of risk involved, ensuring the integrity of static equipment is both a regulatory obligation and a strategic necessity. But what exactly qualifies as static equipment? And why does its [...]

Vidya Expands Digital Integrity Management to New Markets with Scalable Technology

Curitiba, June 13th, 2025 Vidya Technology announces the launch of its Digital Asset Integrity Management Suite, a set of integrated tools that enables full control over the integrity lifecycle from detection to resolution. Combining Artificial Intelligence, Digital Twins, and Spatial Computing, the new solution delivers a contextualized, end-to-end visualization of physical assets, allowing faster and better-informed decisions while enhancing safety, reducing downtime, and cutting operational costs. Originally founded at COPPE/UFRJ, Vidya has become a recognized player in offshore software solutions. Its visual inspection automation technology, which uses computer vision to measure and classify surface corrosion, currently holds 57% of the [...]

FPSO Integrity 101: Challenges, Strategies, and the Path Forward

FPSOs (Floating Production, Storage, and Offloading units) sit at the intersection of extreme engineering and long-term economic strategy. Their presence in deep and remote offshore fields enables oil and gas production in places where fixed infrastructure would be impossible. Every component of the vessel is continuously exposed to harsh saltwater conditions, structural fatigue, variable loads, and mechanical stress. Corrosion slowly attacks hulls, risers, and topside equipment. Repetitive motions induced by waves and mooring tensions generate fatigue in welded joints and critical structures. And over time, these forces accumulate. And yet, many operators still treat integrity as a secondary concern [...]

![Image of a woman using Vidya System Platforms [VSP] on a tablet.](https://vidyatec.com/wp-content/uploads/2025/11/1-capa-blog-CS@2x-320x202.png)